Industry and production

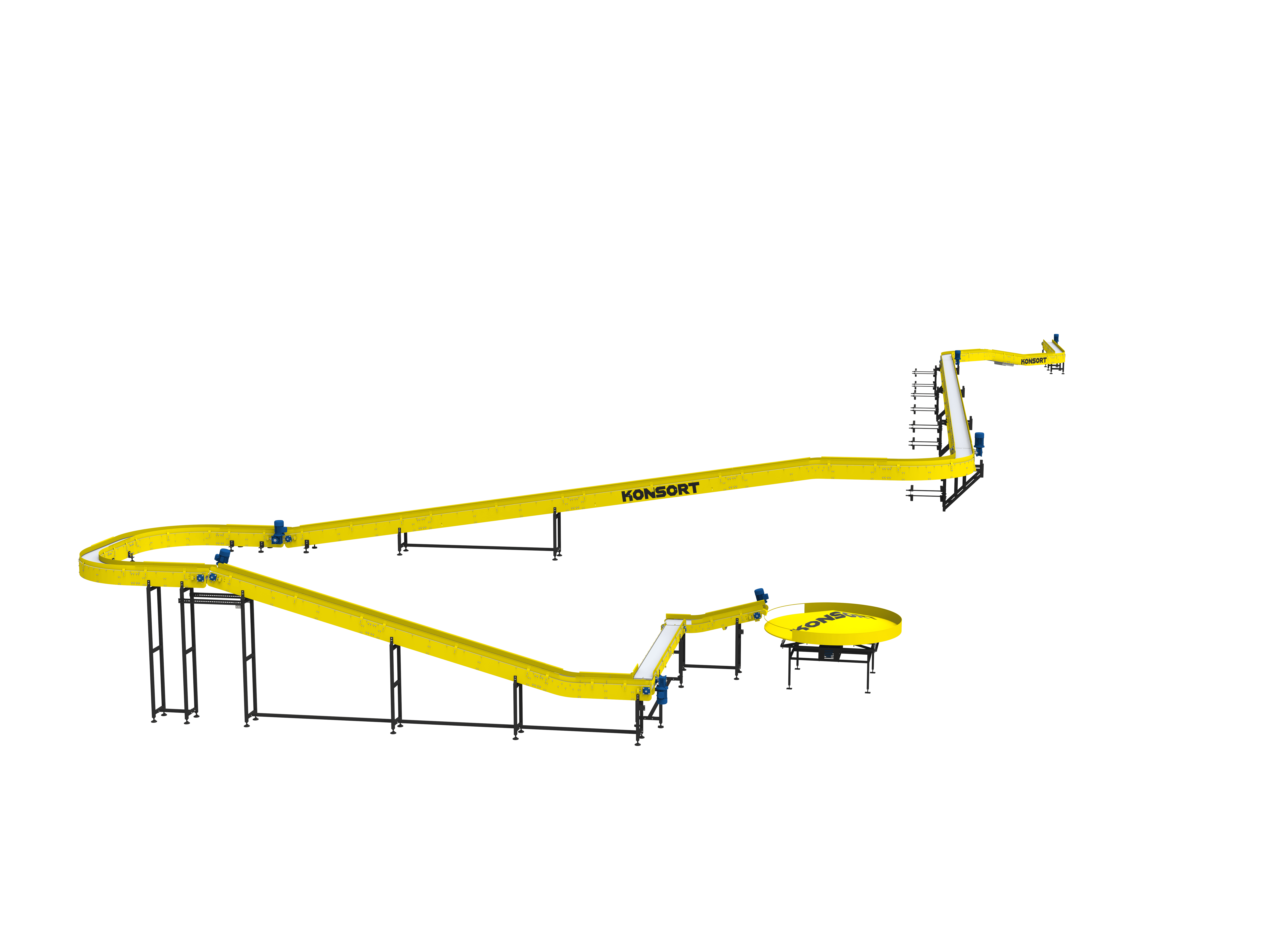

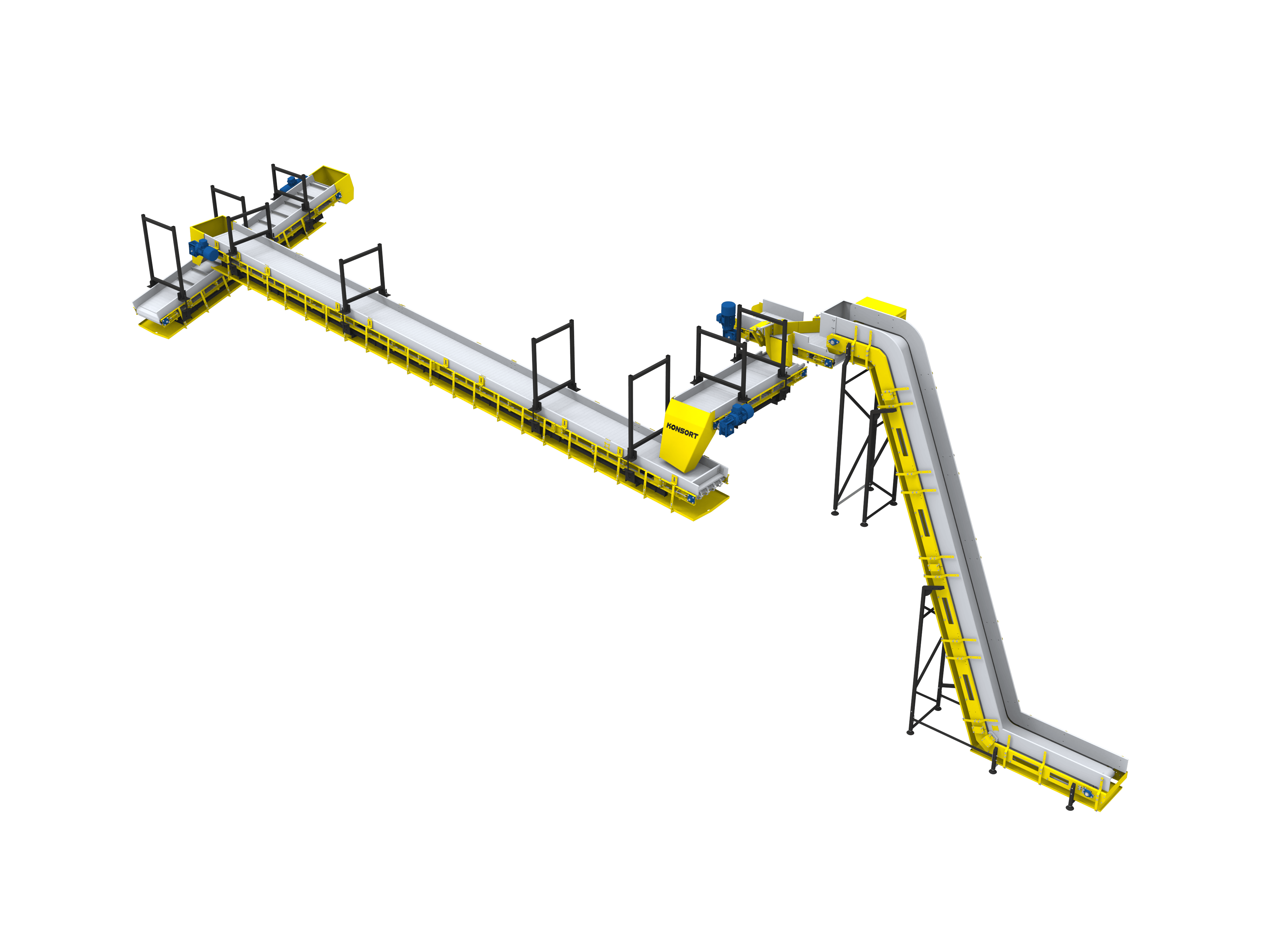

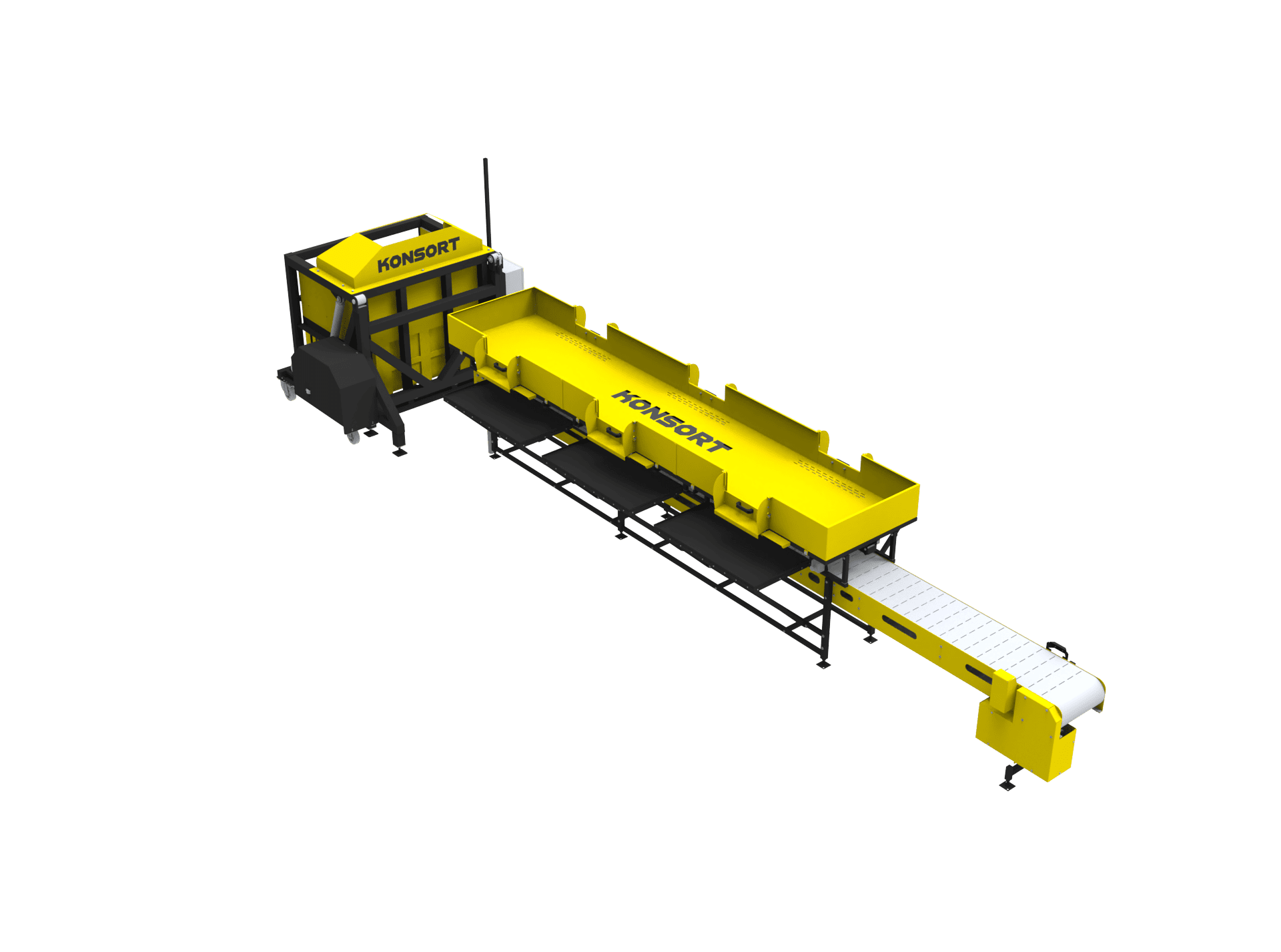

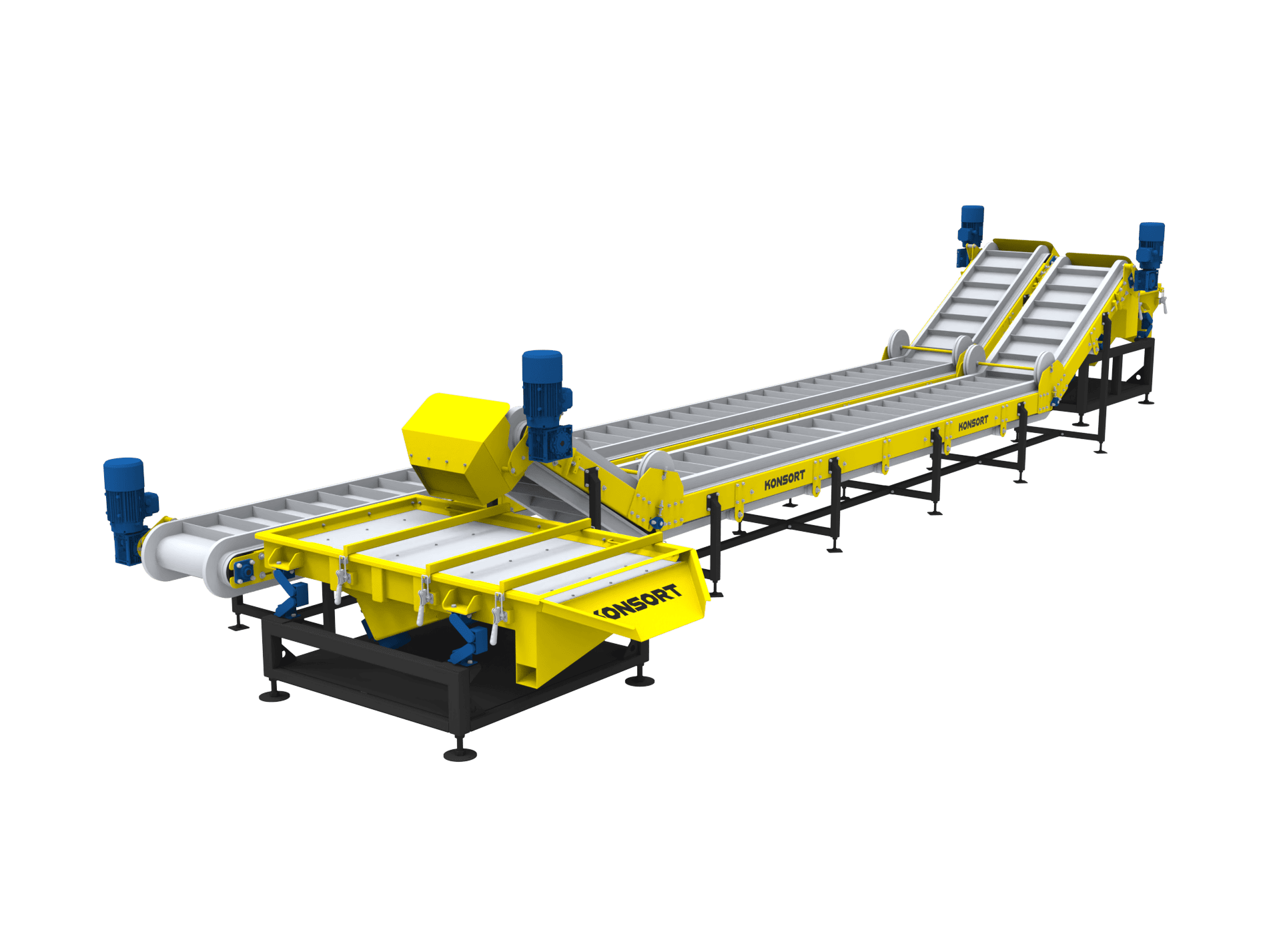

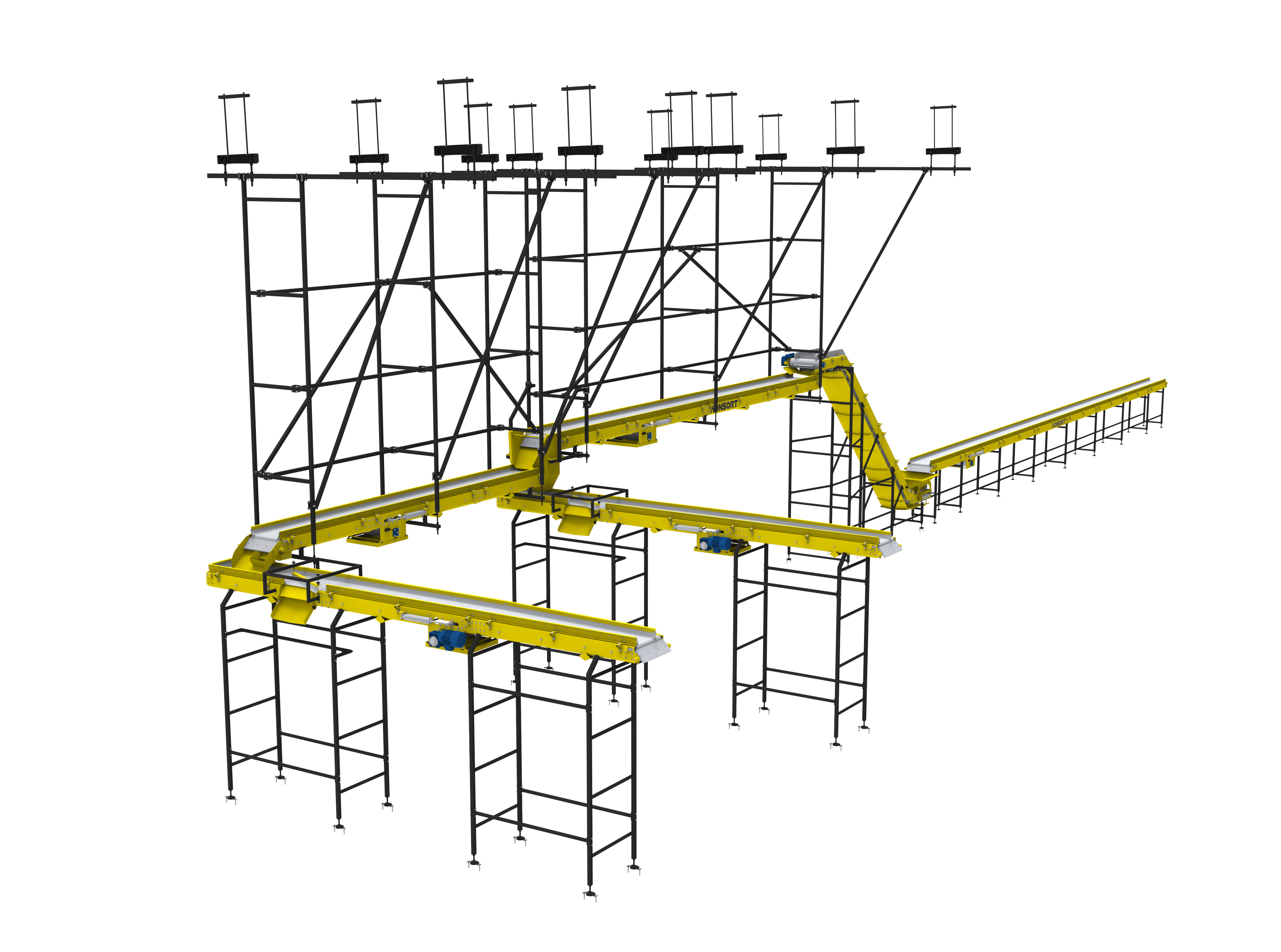

Conveyor equipment for production automation

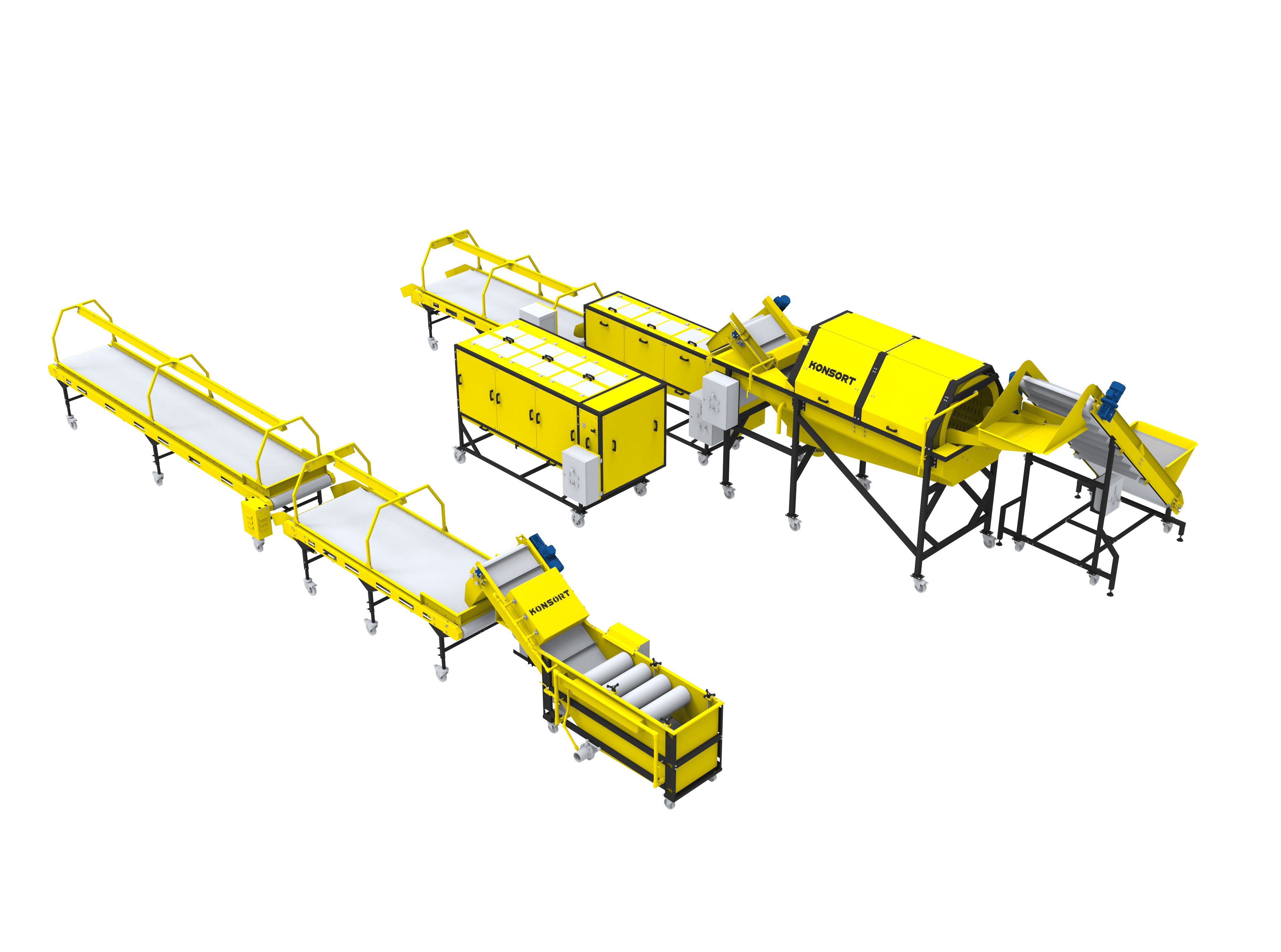

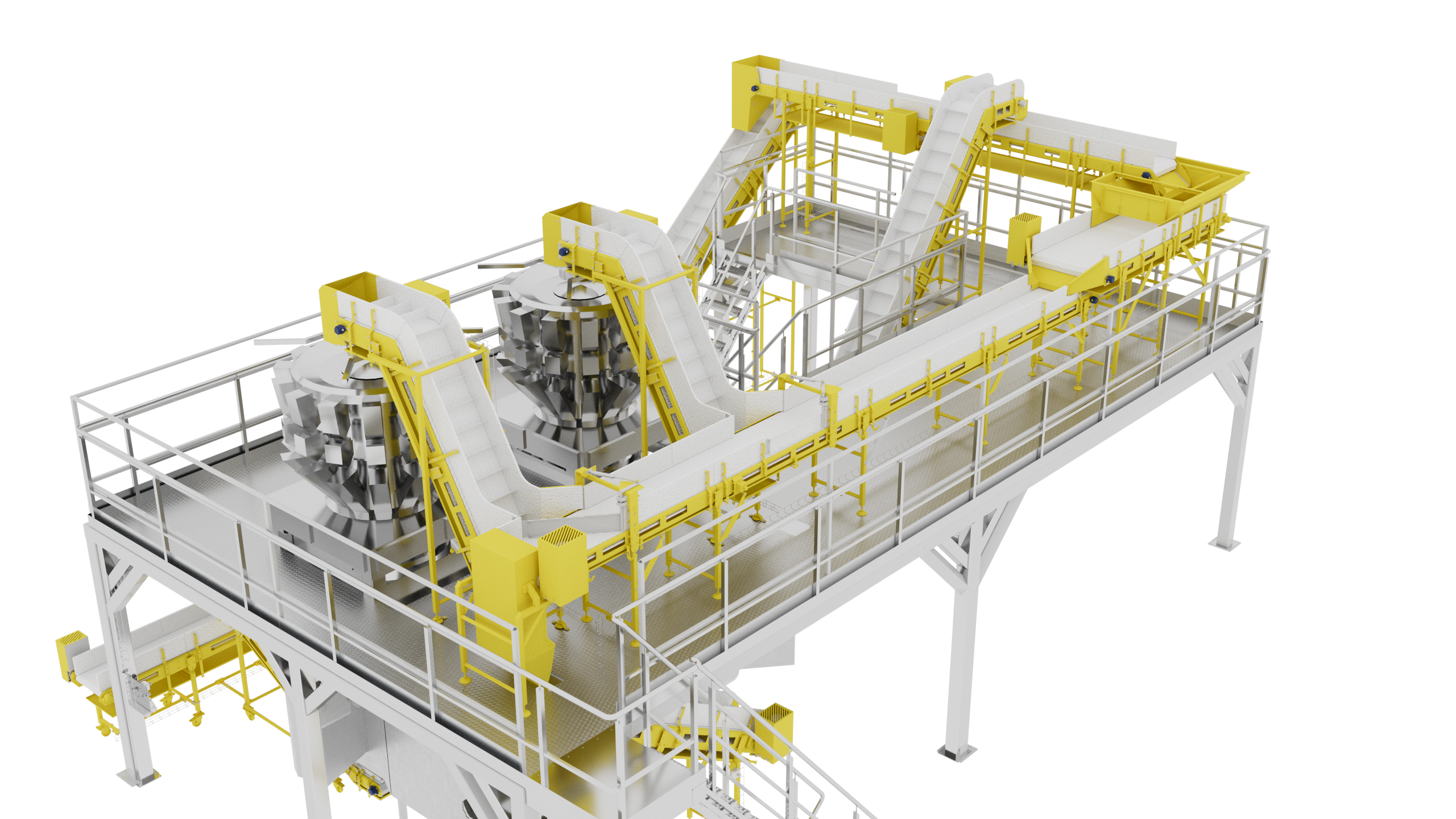

Conveyor solutions for production automation are complex technologies and equipment aimed at optimizing production processes in various industries.

These solutions enable the automation of various production steps, including warehousing, sorting, transportation, processing, counting, weighing and packaging of products. They help increase productivity, reduce costs, improve product quality, and ensure efficient use of resources.

Thanks to conveyor solutions, enterprises can achieve a significant increase in the efficiency of their production activities and ensure competitiveness in the market.

Types of conveyor equipment and their functions:

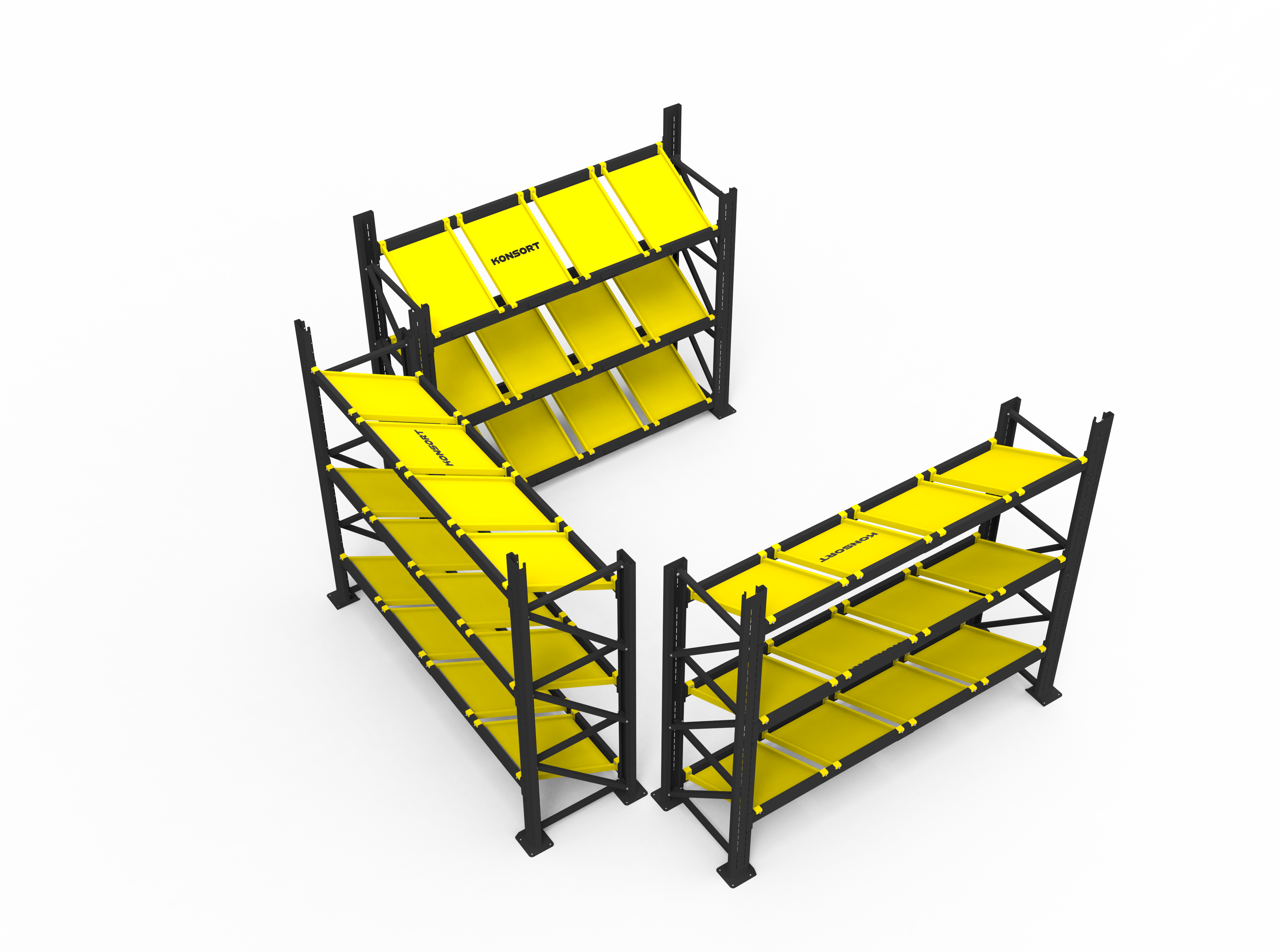

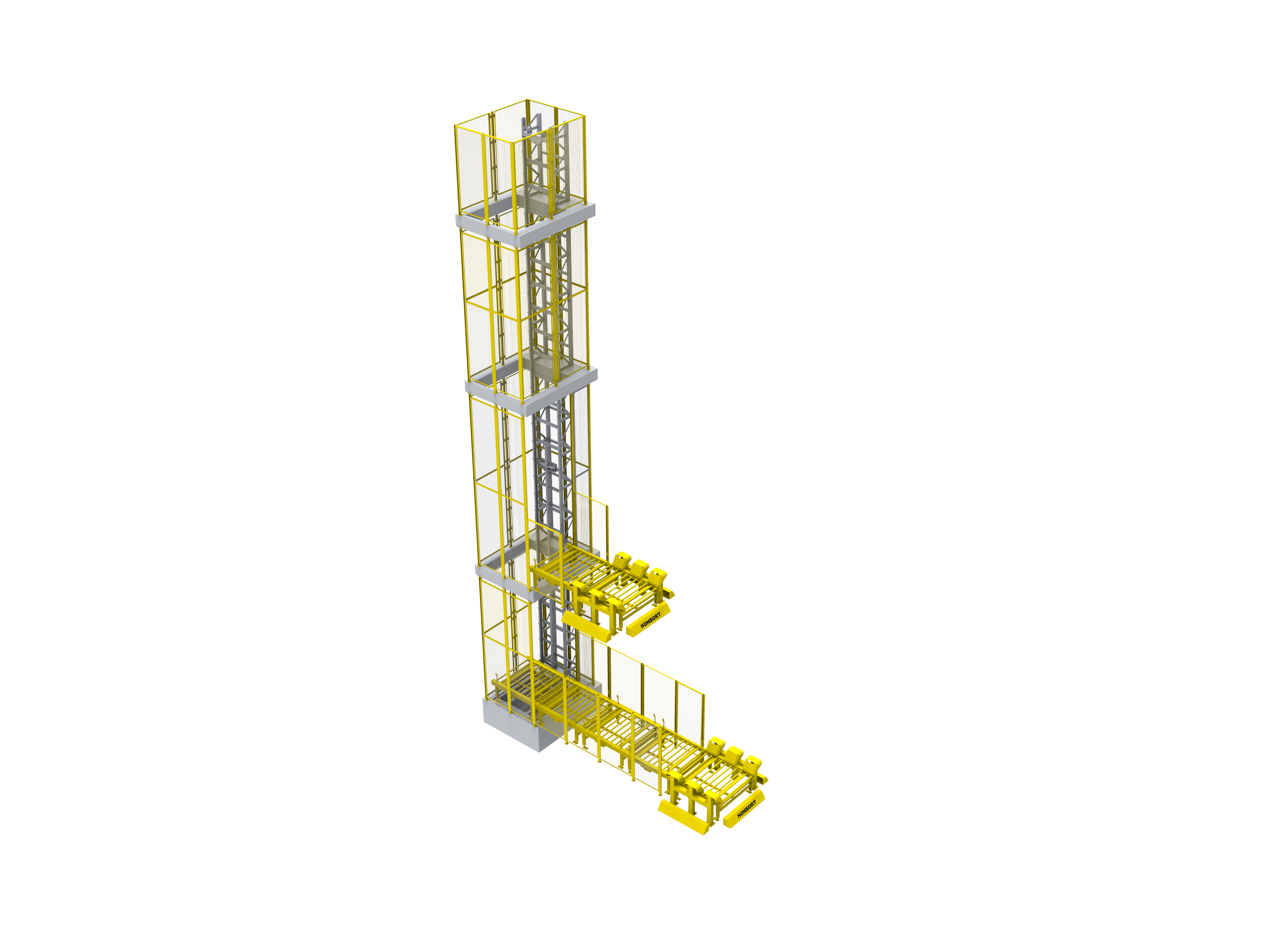

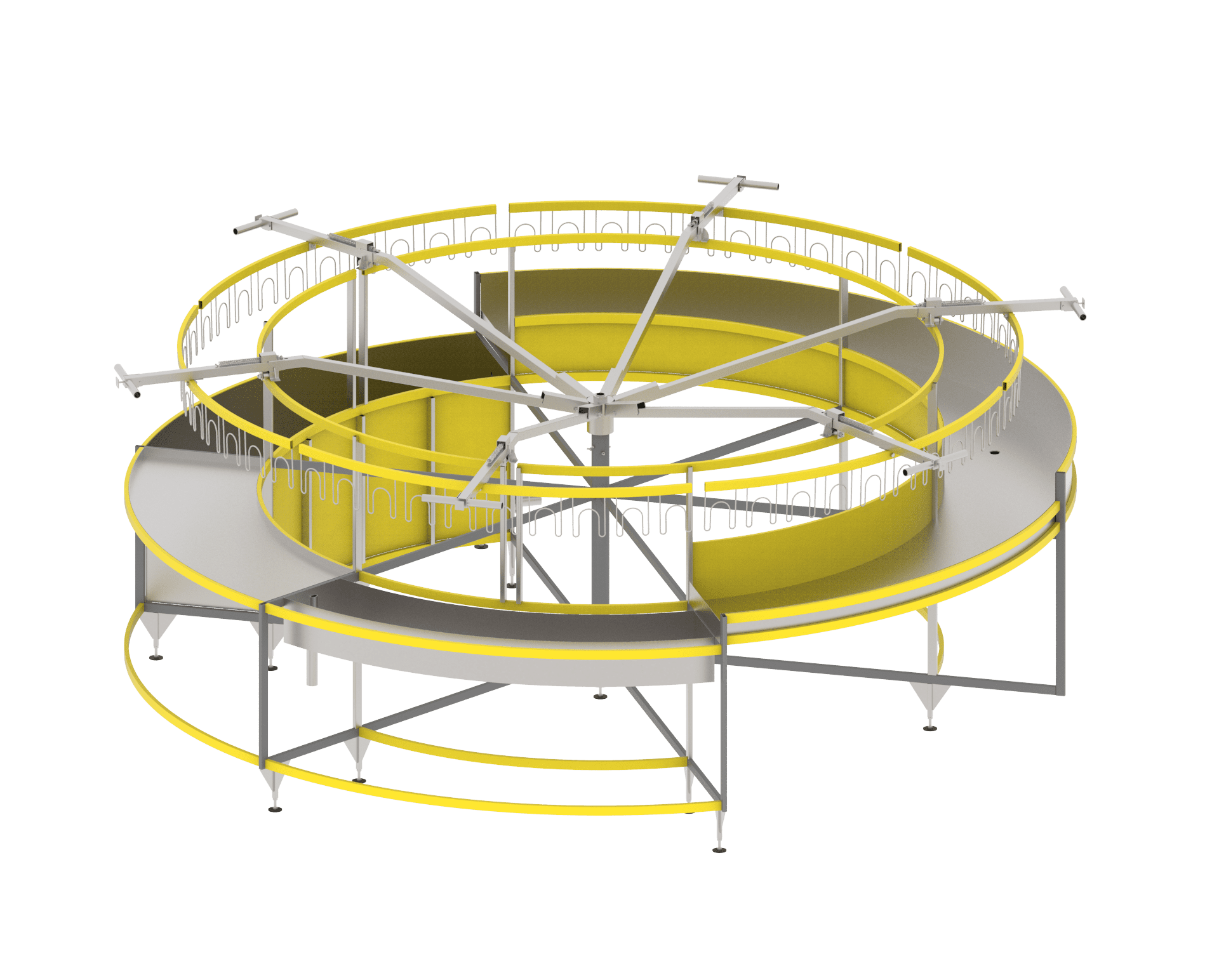

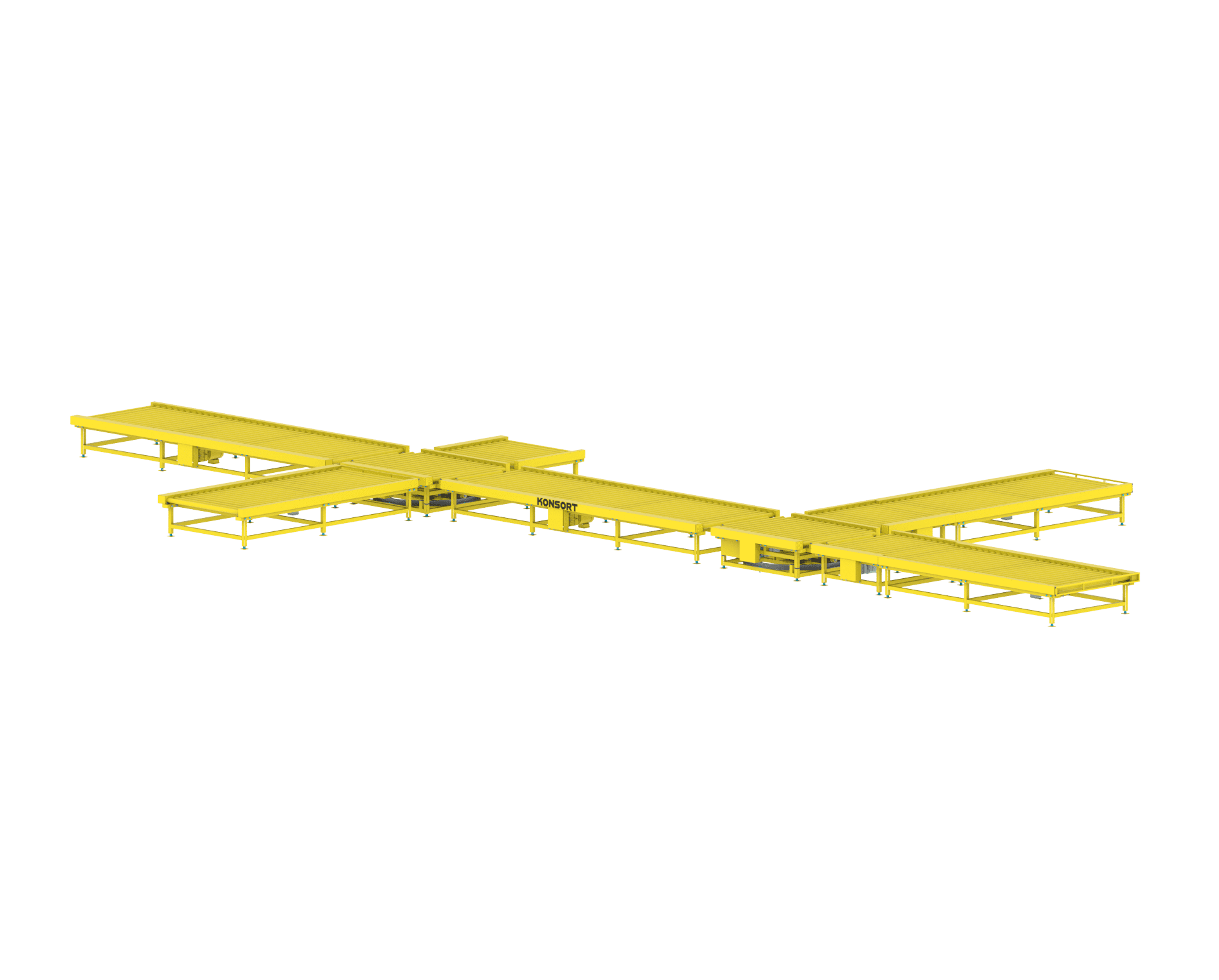

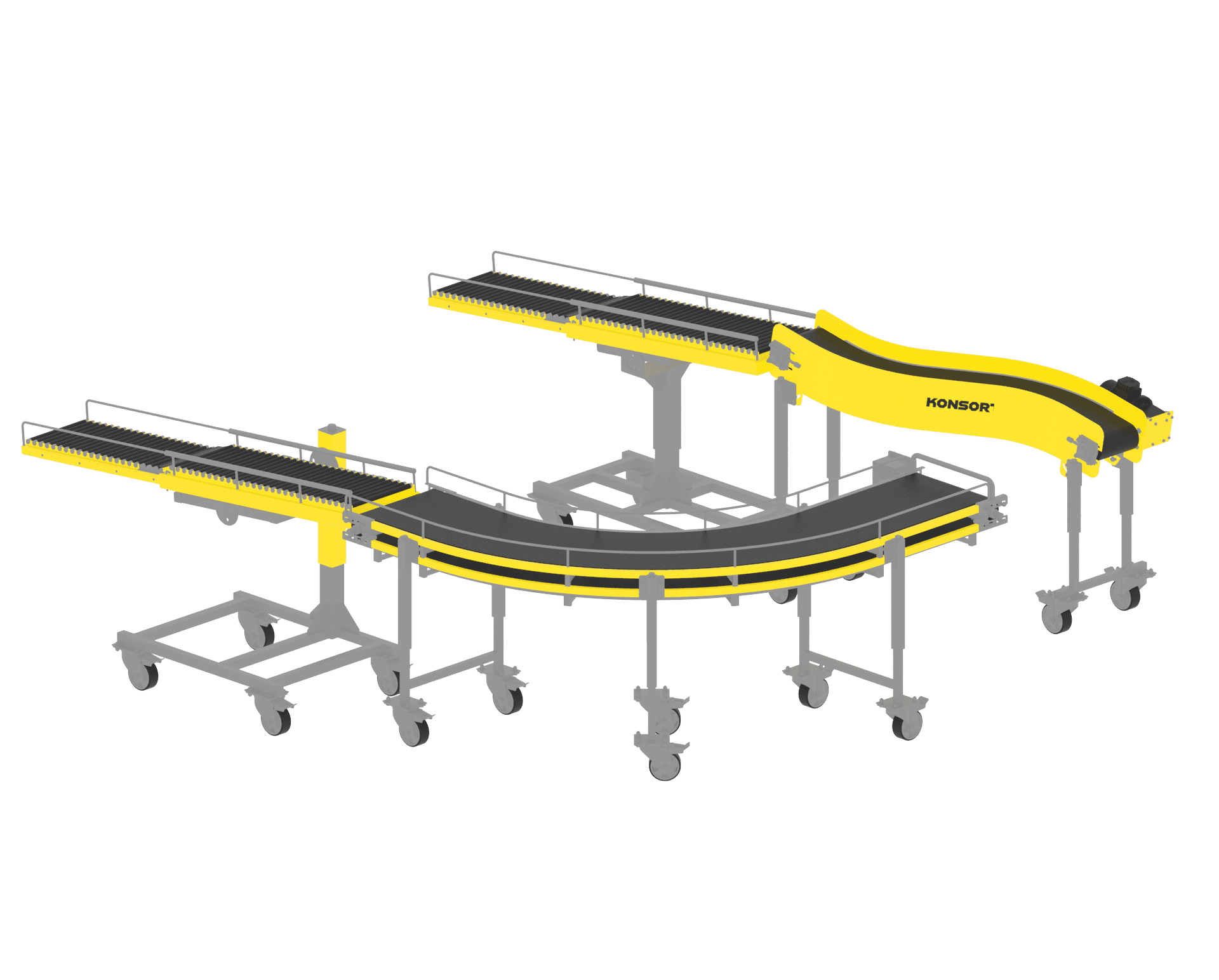

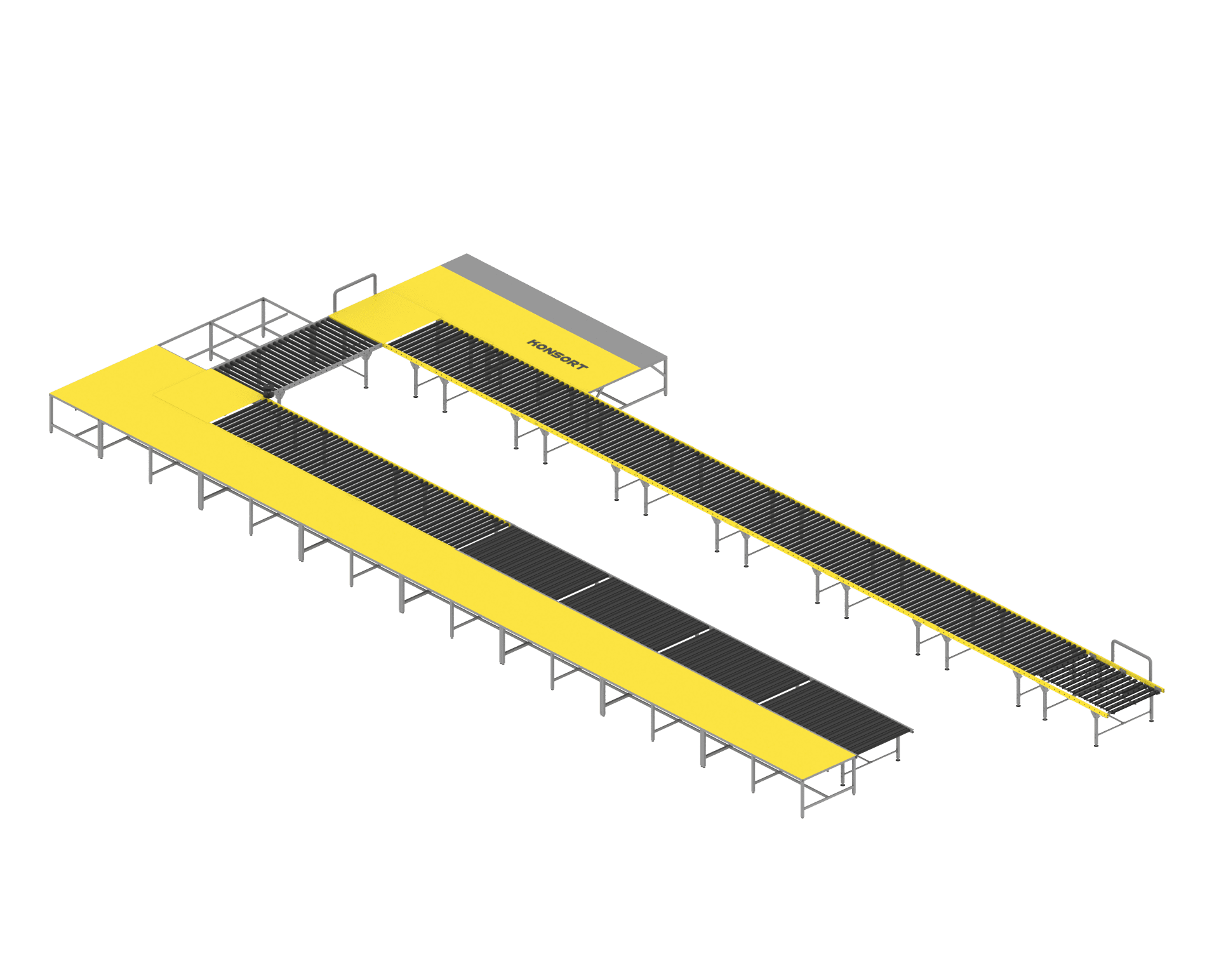

Warehouse conveyors: provide organized storage and movement of materials in the warehouse.

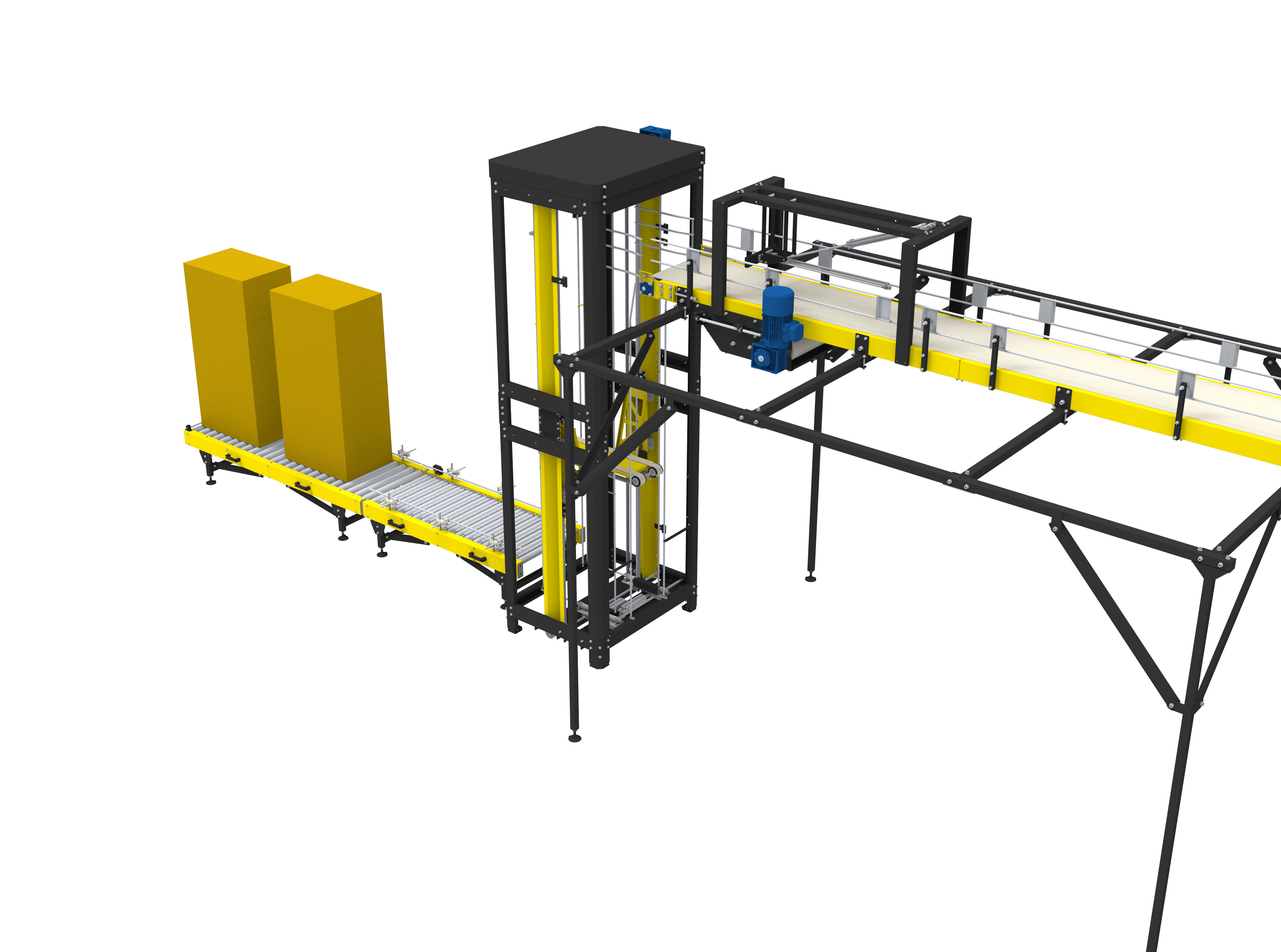

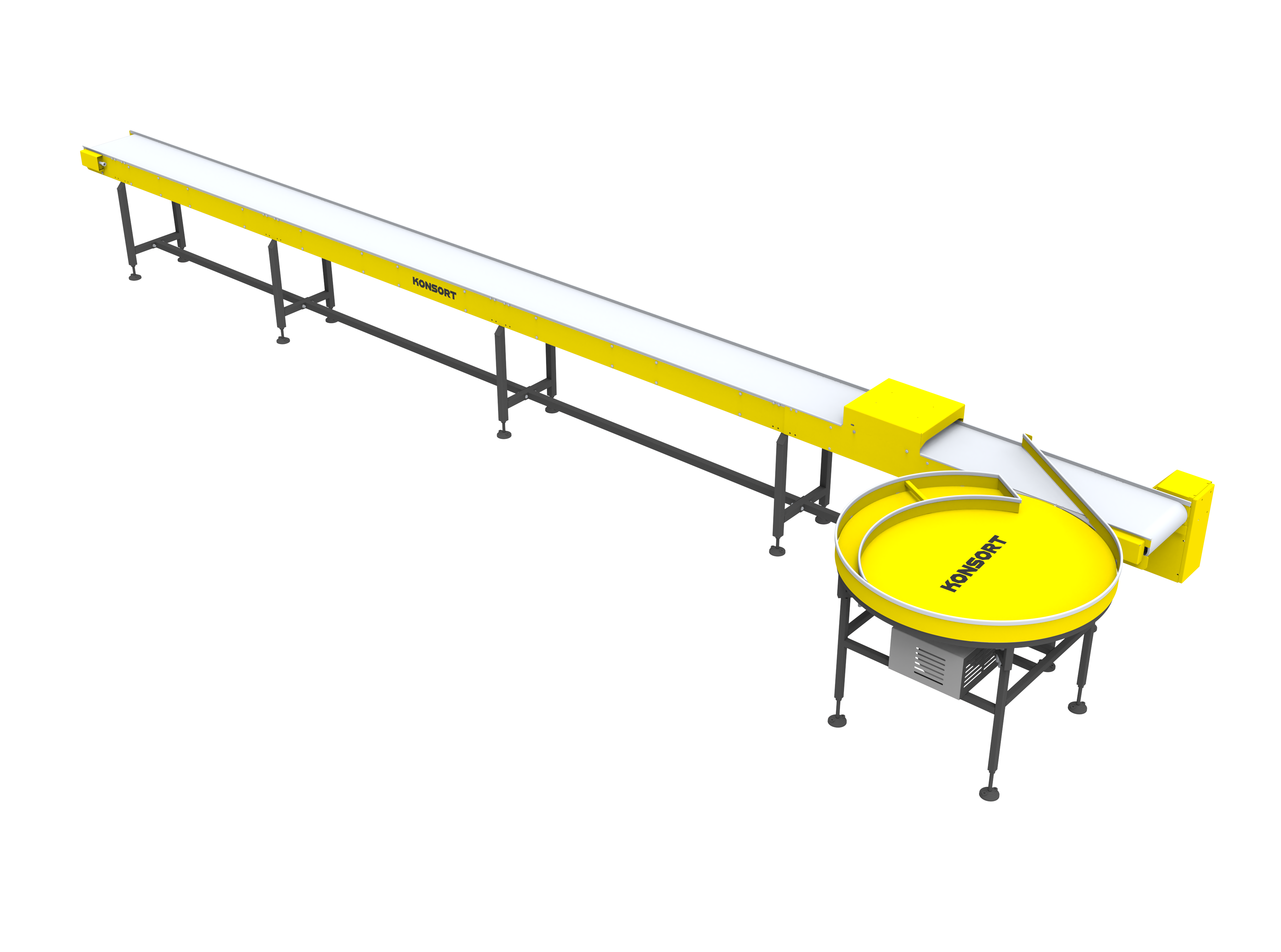

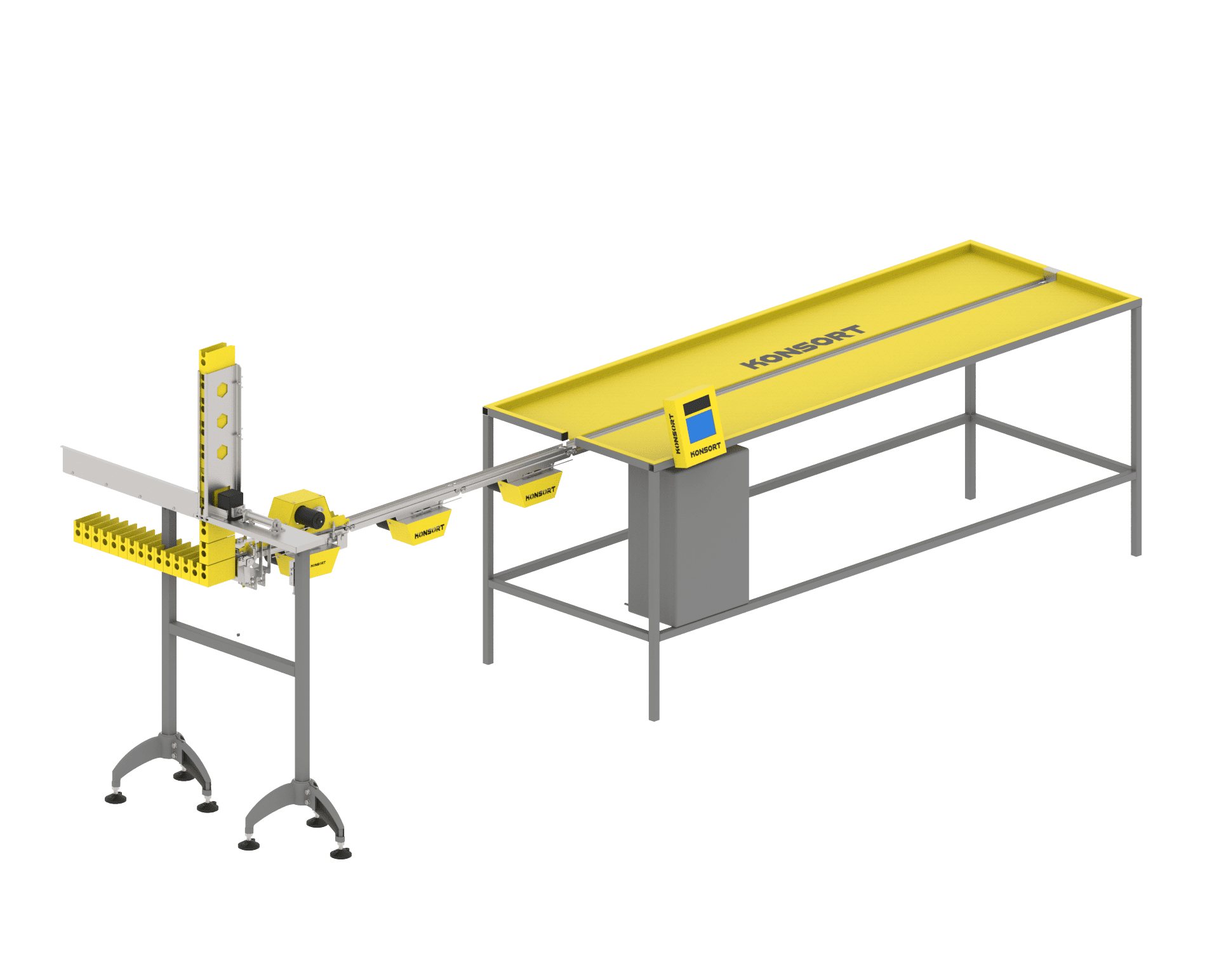

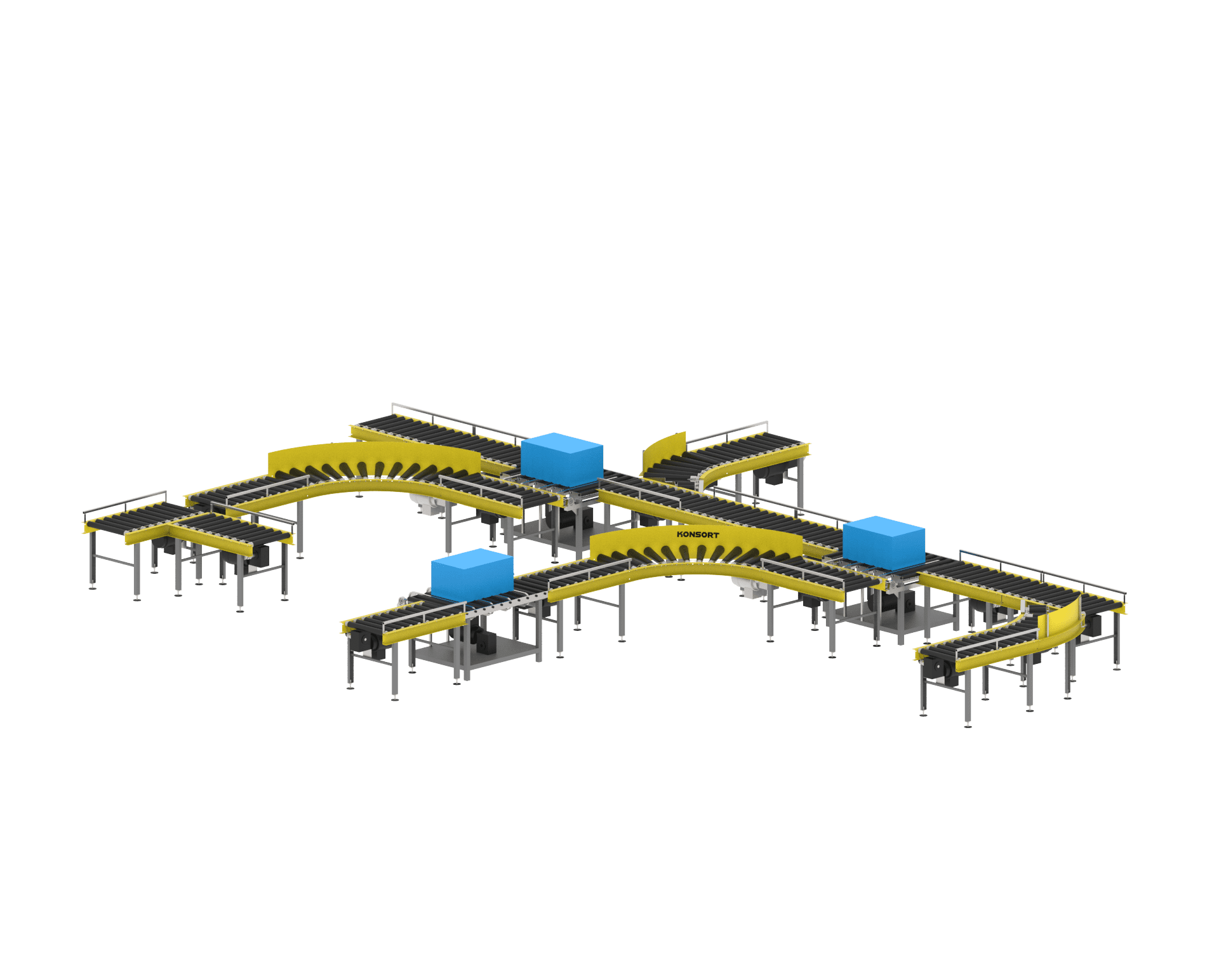

Sorting conveyors: automatically distribute products according to parameters or barcodes.

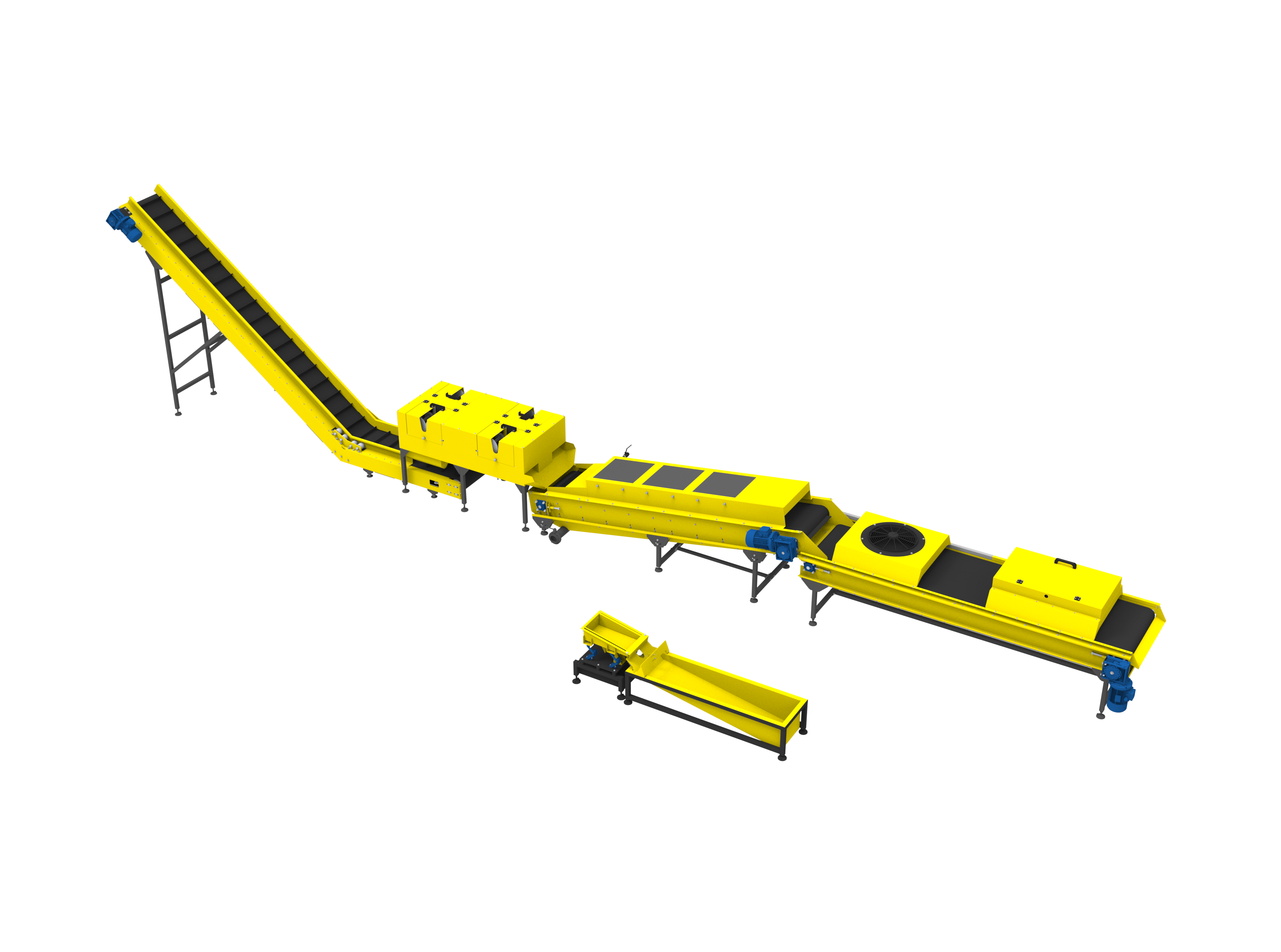

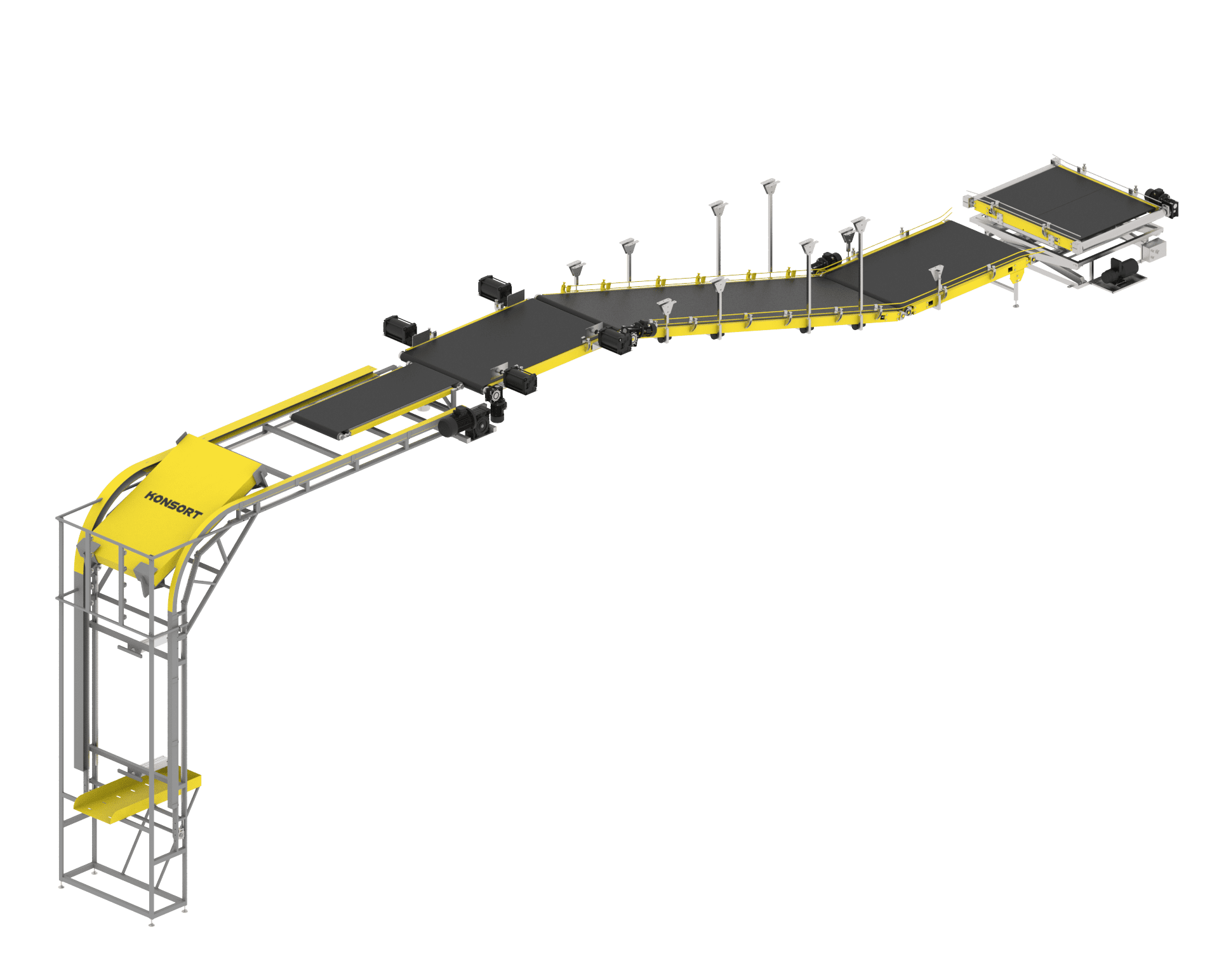

Conveyors: move products along the production line.

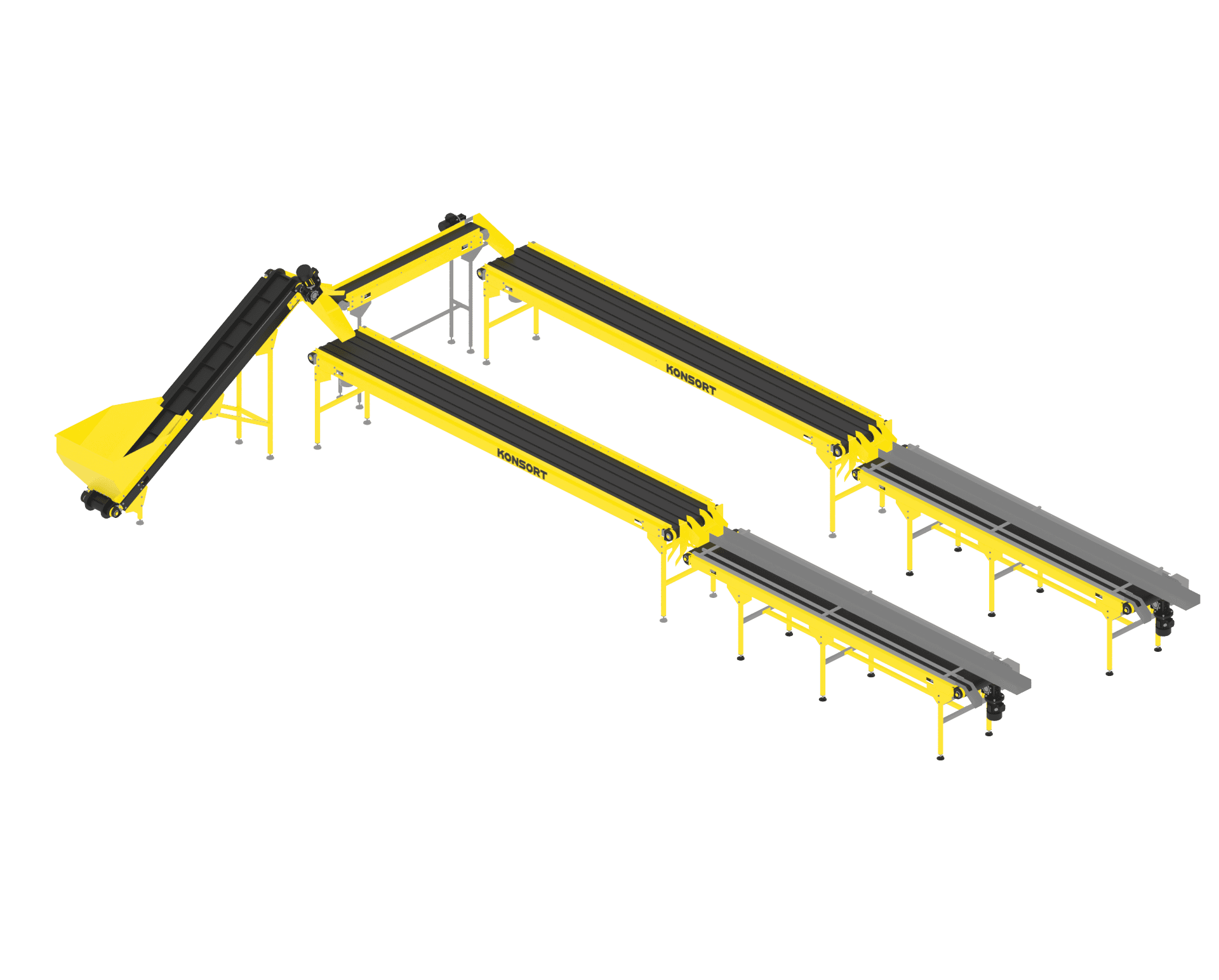

Conveyors for processing: used for processing raw materials at various stages of production.

Conveyors for counting: automatically count the number of units of production.

Conveyors for weighing: measure the mass of products during transportation.

Packaging conveyors: automatically pack products before shipping.

Automation solutions for industrial enterprises provide the following advantages:

Increased productivity: Ensure faster and more efficient execution of production processes, which leads to an increase in production capacity.

Cost reduction: Minimize labor and energy costs, optimizing resource use and ensuring equipment is running more efficiently.

Product quality improvement: Automated control and production processes ensure stable product quality and avoid human errors.

Workflow optimization: Reduce the time and effort needed to produce products by automating routine tasks and optimizing production logistics.

Increasing competitiveness: Allowing industrial enterprises to be more flexible and adaptable to changes in the market, ensuring a quick response to demand and reducing the time from development to production of new products.

Buy a conveyor for automating the production process in Ukraine:

Consultation and selection of equipment: Our specialists will help you choose the optimal conveyor solution, taking into account your needs and production features.

Delivery and installation: We provide fast delivery and professional installation of equipment directly at your business. + Warranty 18 months. for equipment and maintenance.

Service: We provide constant support and maintenance to ensure the reliable and efficient operation of your equipment during the entire period of operation (24/7 service throughout Ukraine).

Don’t waste time and opportunities to optimize your production process with conveyor solutions from KONSORT. Contact us today to start working together!