Lecithin bottling line

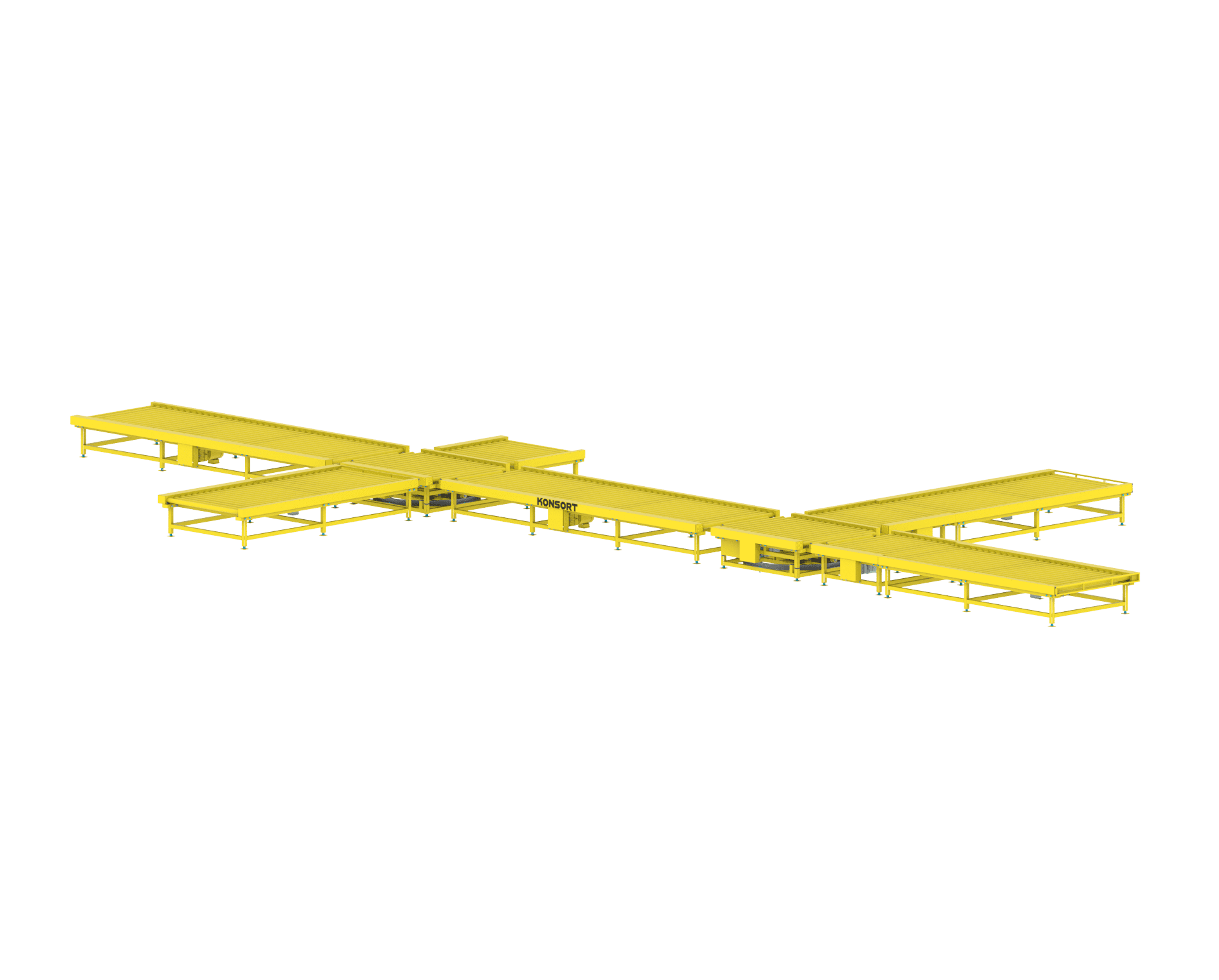

The lecithin bottling line consists of a roller system and a turntable. Roller table frame is made with the help of cold galvanizing and rollers with galvanic galvanizing. The line is equipped with gearboxes with power from 1.5 kW to 3 kW and with frequency converters with the same characteristics. Connection to the power supply is 380 Volts. The following electrical equipment was installed: control box, motion control sensors, power cables, emergency stop system, controller, sound and light alarm, button post. This line works according to the following algorithm: the operator sets the pallet on conveyor N1, then presses the start button on the button post. The post is installed in the nonoccupied area, with an emergency STOP button that stops all conveyors. Next, the operator presses the button “Feeding pallets” on the filling machine. Then conveyor N4 starts. After the pallet from conveyor N4 goes to the filling machine, filling of conveyors N3, 2, 1 starts automatically. When the operator presses the button “Departure of full barrels”, the machine starts conveyor N5 and stops by the conveyor filling sensor. The next start of conveyor N5 will be after the operator presses the button Departure of full barrels” on the filling machine.

Improving in the organization of production and management by 55%

Improving in the organization of production and management by 55%  Productivity increase up to 80%

Productivity increase up to 80%  Lower production costs by 40%

Lower production costs by 40%  Reduction in human-related risks by 20%

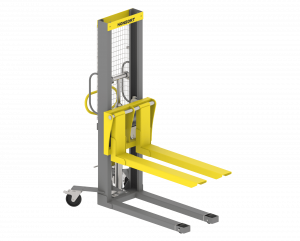

Reduction in human-related risks by 20% - To transport barrels and other bulky goods in food and agricultural industry.

- At the enterprises of oil refining and oil industry.

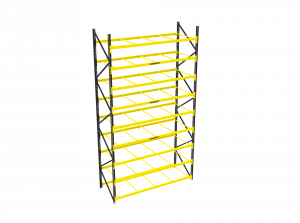

- European design provides a professional and clean look

- Durable powder coating

- There is possibility to complete the line with extra components if necessary

- European components are used