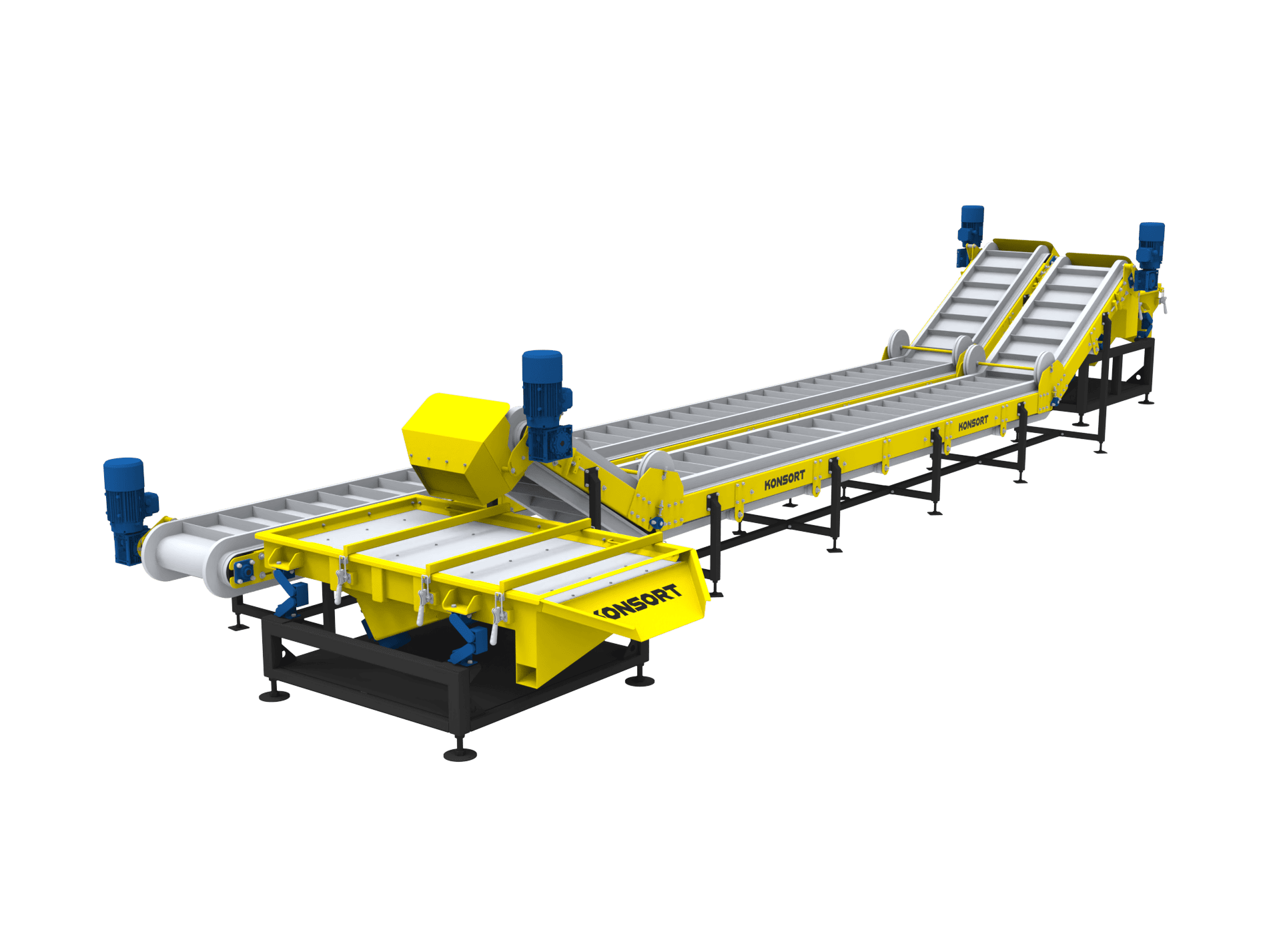

Pasta processing line

Pasta processing line

Description

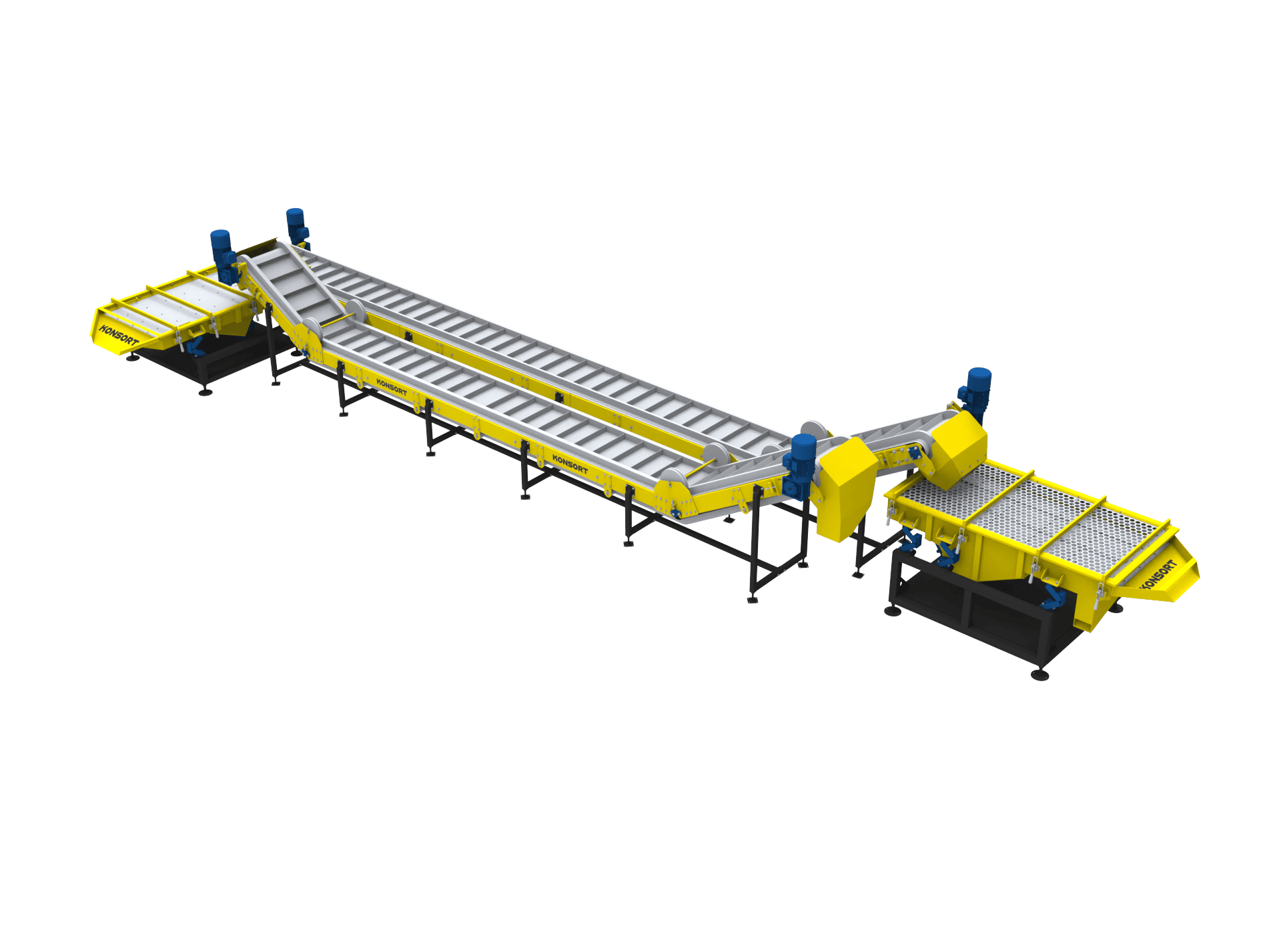

The pasta production line is modern and reliable equipment designed to automate the processes of manufacturing, sorting, and feeding pasta products within the food industry. Due to its multifunctional design, this conveyor system effectively transports products while preventing damage. Additionally, the integrated vibrating calibrators ensure a uniform distribution of pasta of various shapes for subsequent processing stages.

Components:

- L-shaped conveyor – for vertical and horizontal pasta transportation

- V-shaped conveyor – for feeding the product at an optimal angle

- Vibrating sieve – for efficient sorting and separation of crumbs from whole pasta

Advantages:

✅ Automated sorting and transportation of pasta

✅ Reduced product breakage

✅ Optimal distribution of different pasta shapes

✅ Durable design using food-grade materials

✅ Easy to use and maintain

Order an automated conveyor system for pasta transportation and sorting at the best price directly from the manufacturer in Ukraine!

Improving in the organization of production and management by 65%

Improving in the organization of production and management by 65%  Productivity increase up to 60%

Productivity increase up to 60%  Lower labour costs by 78%

Lower labour costs by 78%  Reduction in human-related risks by 40%

Reduction in human-related risks by 40% - Pharmaceutical companies

- (UA) Виробництва напівфабрикатів

- Enterprises specializing in sugar and coffee production

- European design provides a professional and clean look

- Durable powder coating

- There is possibility to complete the line with extra components if necessary

- European components are used