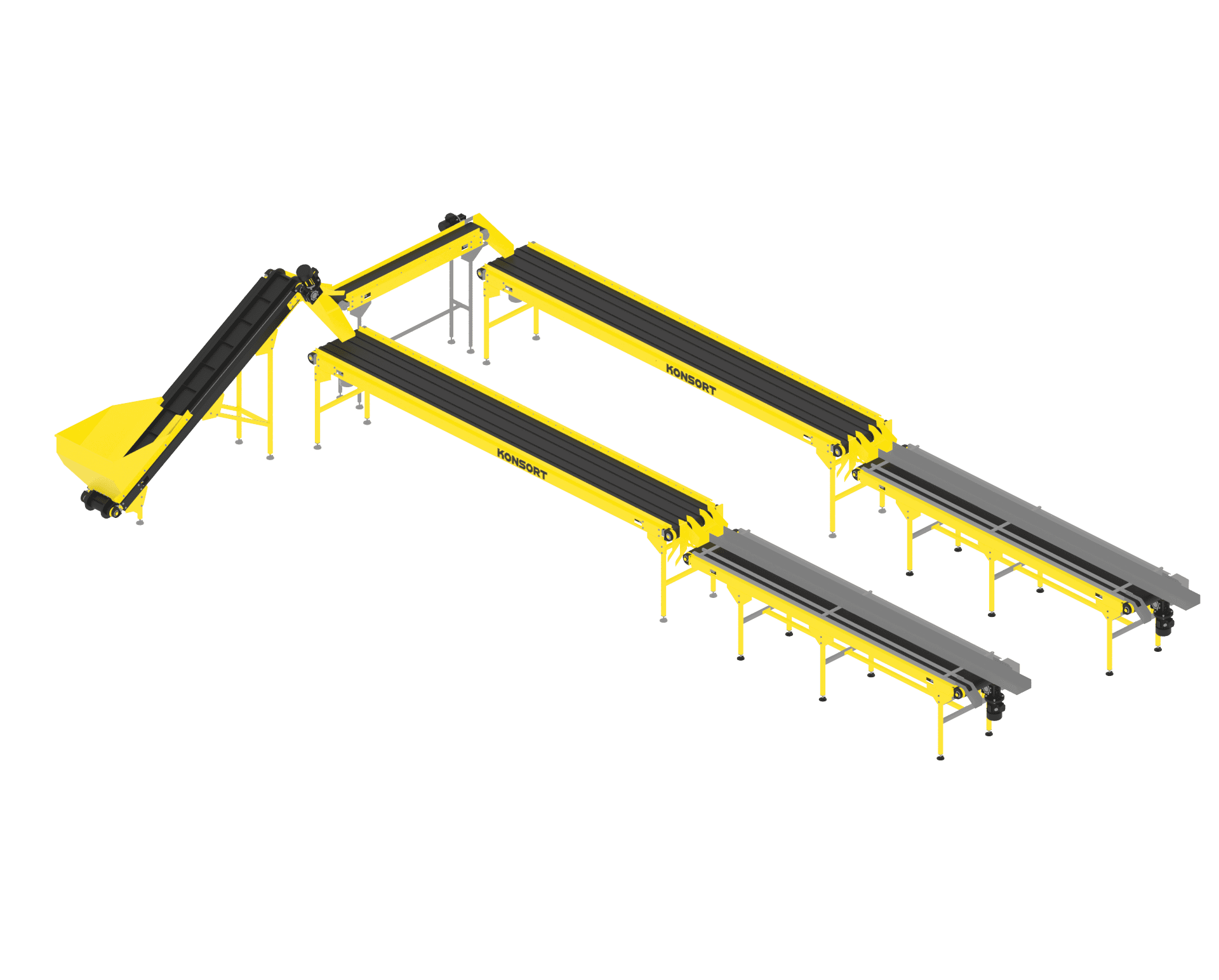

Snail processing line

This line is designed to optimize and to automate the processing of snails. The line consists of a loading conveyor with a hopper, a distribution conveyor, and four inspection conveyors. Each of the conveyors is equipped with a food grade polyurethane belt. Belt tension is regulated with tensioning mechanisms, and supporting rollers prevent the belt from sagging. The drive and tension rolls are mounted on self-aligning bearings in a closed housing. The control box has a belt emergency stop system, start, stop and speed control buttons, and is protected by a corrugated tube. The line can be also additionally equipped with a vibrating sieve for snails.

Technical characteristics:

Polyurethane tape

1,3 mm, Chiorino, Italy

Motor reducer Neri Motori, Italy

1 unit

Connection to power supply

220 Volts

Material used

food grade stainless steel

Frequency converter INVT

1 unit

Line components:

Loading conveyor

1 unit

Flows distribution conveyor

1 unit

Inspection conveyor

4 units

Complete set of vibrating sieves

Overall dimensions

1 000 * 2 000 mm.

Loading height

1 200 mm.

Unloading height

800 mm.

Vibrator with a frequency converter

1 unit

The equipment can be designed according to individual parameters necessary for the customer

Economic advantage:

Improving products quality and grade up to 80%

Improving products quality and grade up to 80%  Productivity increase up to 90%

Productivity increase up to 90%  Lower labour costs up to 60%

Lower labour costs up to 60%  Reduction in human-related risks by 20%

Reduction in human-related risks by 20%

Spheres of usage:

- To inspect, sort and process food products

Benefits and options:

- European design provides a professional and clean look

- The equipment is designed in accordance with all the rules and regulations put forward to the food industry equipment

- There is possibility to complete the line with extra components if necessary

- Production process is automated

(UA) Про нас говорять

With these products are often ordered