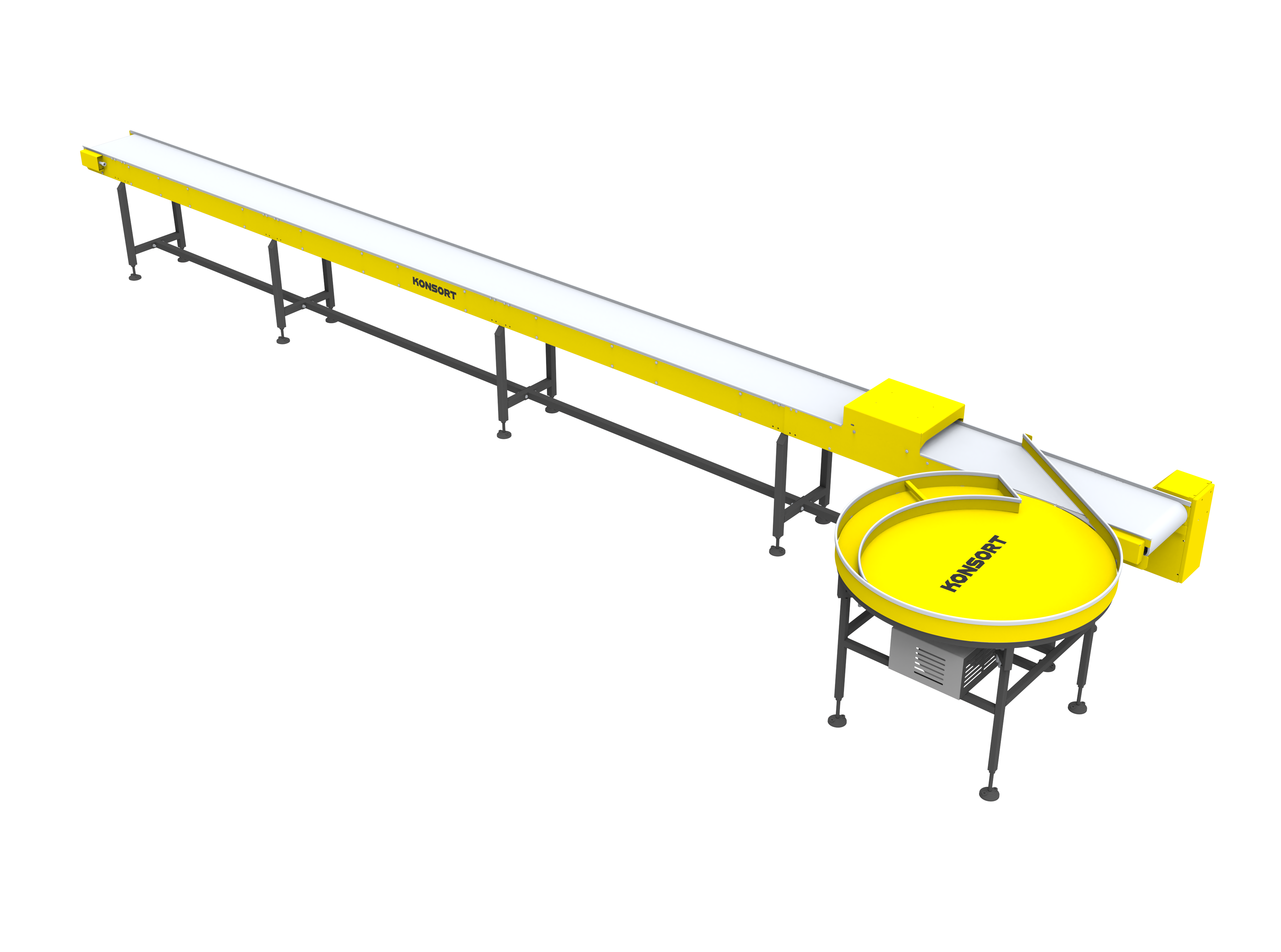

Line for packaging and disinfection of food products

Food packaging and disinfection line — a smart, efficient solution for modern food production

The food packaging and disinfection line by KONSORT is an advanced industrial system that delivers a full-cycle solution for preparing food products for distribution — from hygienic disinfection to reliable box packaging. Specifically engineered for the food industry, this line meets the highest standards of safety, cleanliness, and operational performance.

What is this line designed for?

This automated solution is built to handle:

- disinfection of food containers and boxes using UV treatment;

- conveying and accumulation of products at the production line exit.

The system is easily integrated into existing workflows and is ideal for small, medium, and large-scale food processing businesses.

Key benefits of the KONSORT line:

✅ Full automation — reduces manual labor and human error, increasing overall efficiency

✅ High throughput capacity — enables uninterrupted handling of food containers, perfect for high-volume operations

✅ Modular design — easily tailored to your production needs, whether you require a single unit or a complete system

✅ Certified materials — all contact surfaces are made from AISI 304 stainless steel, ensuring food safety and corrosion resistance

✅ Seamless integration — compatible with existing conveyor, packaging, cooling, and sorting lines

Why choose a KONSORT packaging and disinfection line?

- Made in Ukraine — fully developed, manufactured, and tested in-house.

- Factory-direct pricing — no middleman, no extra costs.

- End-to-end support — includes installation, commissioning, and staff training.

- Custom-fit design — we adapt dimensions and functions based on your production environment.

- Trusted internationally — exported to over 18 countries and counting.

Order your KONSORT food packaging and disinfection line today — and bring automation, hygiene, and reliability to every step of your food packaging process.

Improving in the organization of production and management by 50%

Improving in the organization of production and management by 50%  Productivity increase up to 80%

Productivity increase up to 80%  Lower production costs by 40%

Lower production costs by 40%  Reduction in human-related risks by 20%

Reduction in human-related risks by 20% - Production of ready meals and semi-finished products

- Factory kitchens and catering enterprises

- Dairy and cheese processing plants

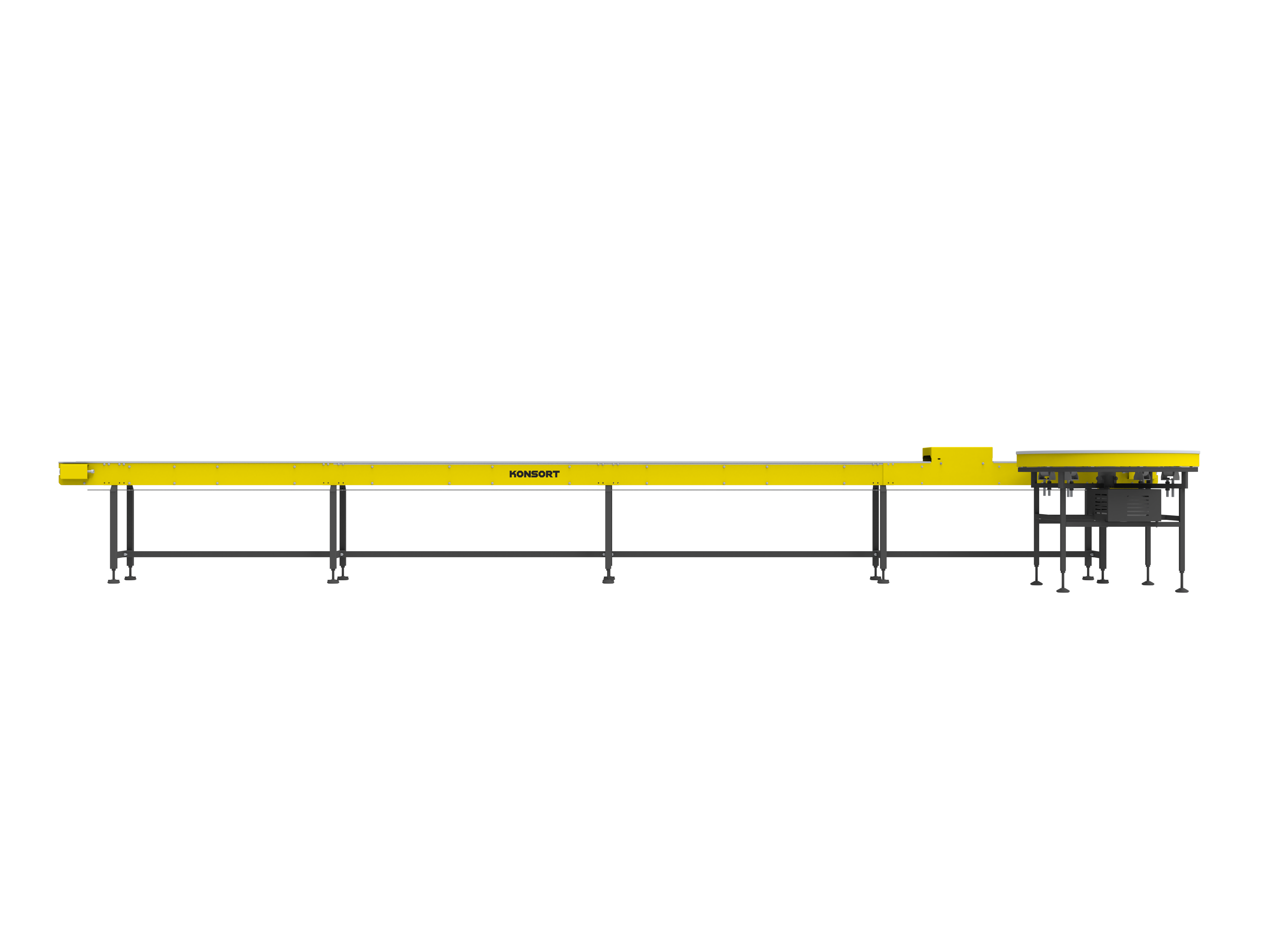

- European design provides a professional and clean look

- Durable powder coating

- There is possibility to complete the line with extra components if necessary

- Production process is automated

- There is possibility to install sound and light alarms