Bread transportation line

Buy a bread transporting line directly from the manufacturer (Ukraine)

Description

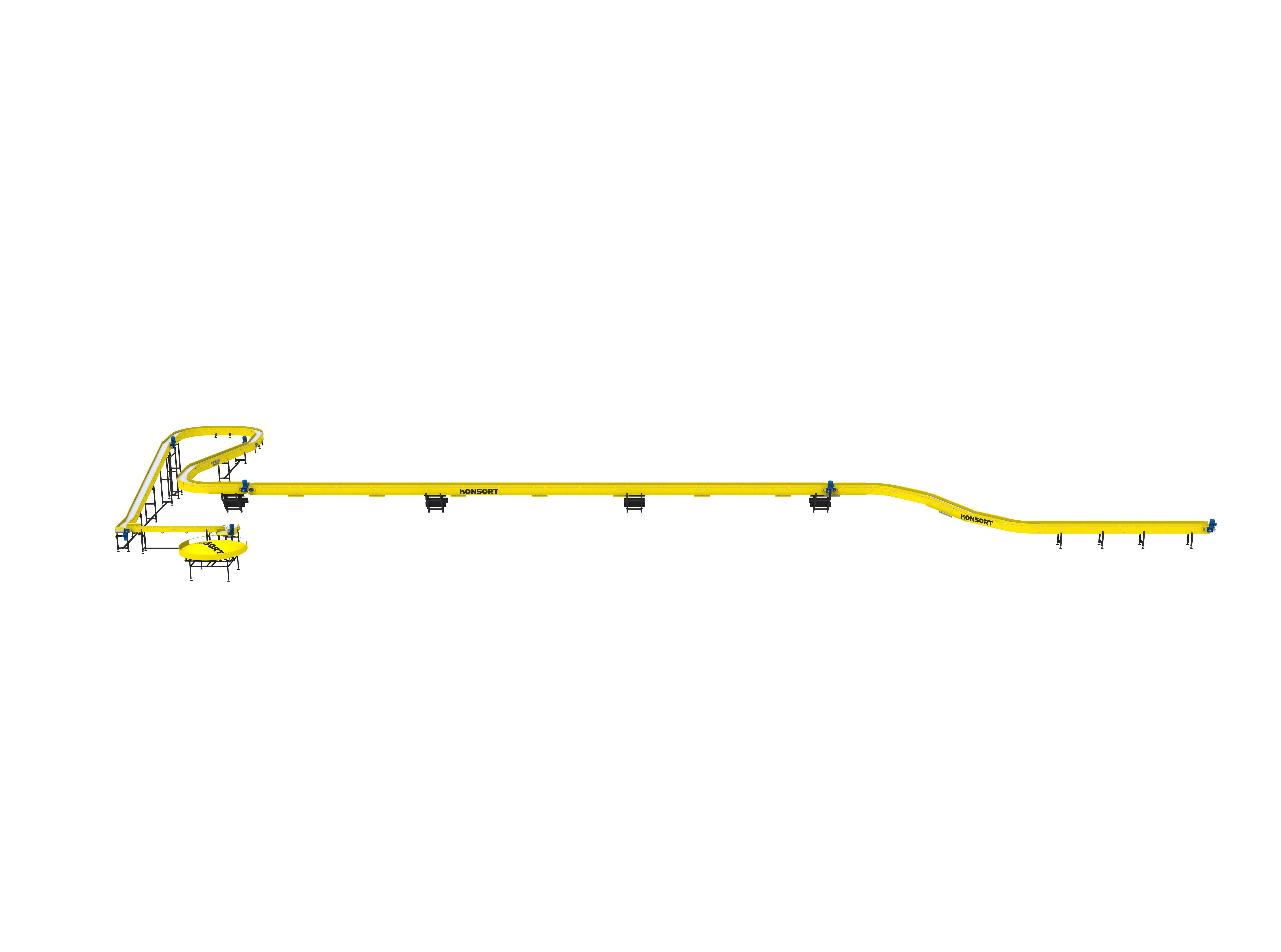

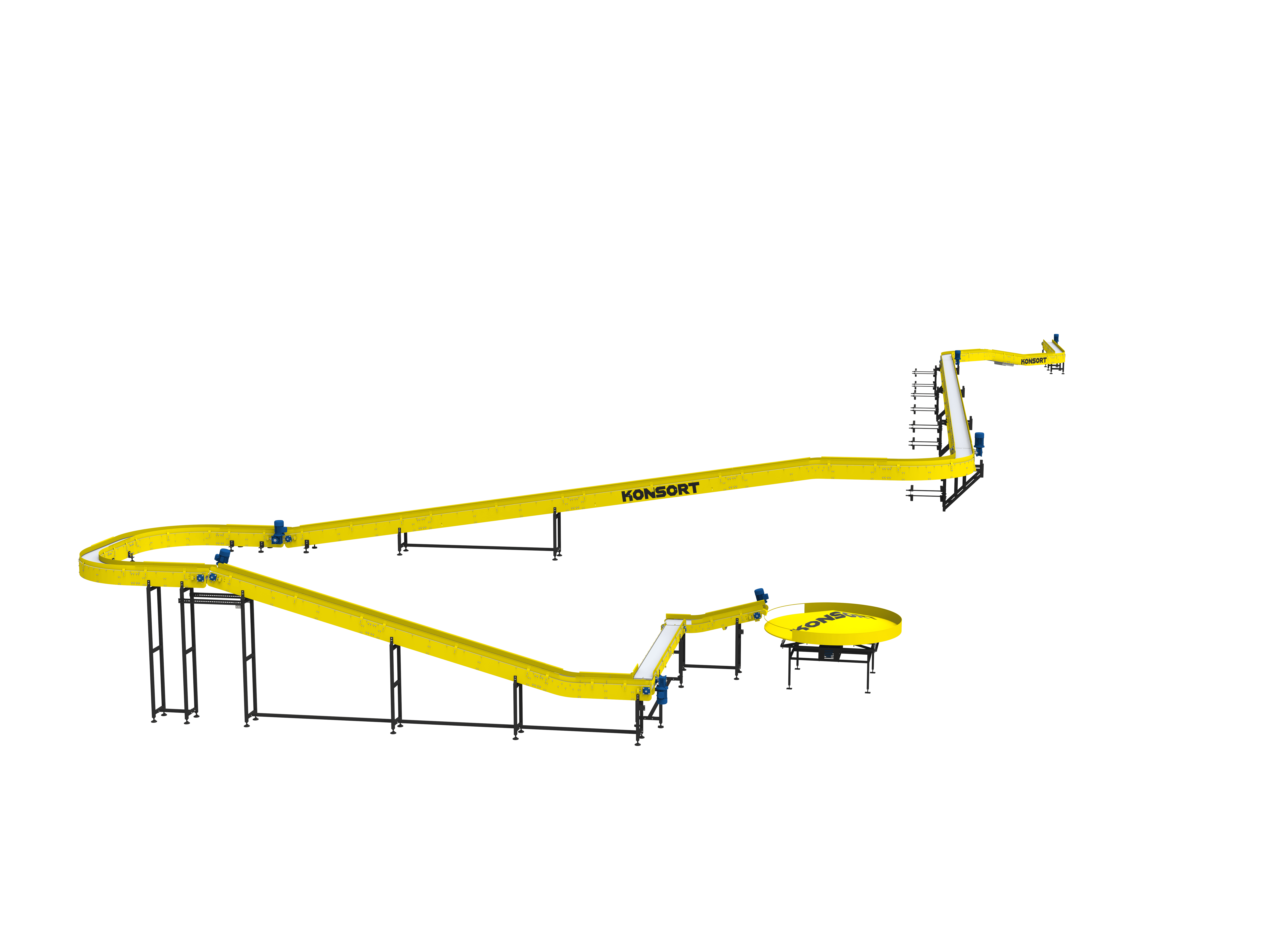

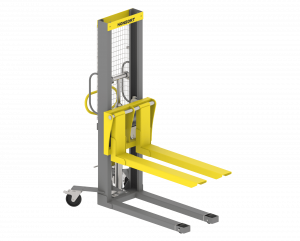

The bread transport line is designed for the automated transfer of freshly baked bread from the oven to a spiral conveyor for further cooling. When exiting the oven, the bread temperature reaches approximately 100°C, so the system utilizes a heat-resistant food-grade belt to ensure safe and efficient transportation.

The system evenly distributes bread without the risk of damage or process interruptions. The use of a curved conveyor and rotating table optimizes the product flow logistics.

Components:

✅ Curved conveyor – for changing the product’s movement direction

✅ Conveyor for transporting bread to the cooling conveyor

✅ Stationary belt conveyor – for stable bread transportation

✅ Rotating table – for even product distribution

Advantages:

✅ High-temperature resistance of the belt

✅ Automation of the transportation process

✅ Continuous product flow

✅ Minimization of bread damage risk

✅ Optimal integration into production lines

Order the bread transport line directly from the manufacturer – ensure a seamless production and transportation process for your products!

Improving in the organization of production and management by 65%

Improving in the organization of production and management by 65%  Productivity increase up to 60%

Productivity increase up to 60%  Lower labour costs by 78%

Lower labour costs by 78%  Reduction in human-related risks by 40%

Reduction in human-related risks by 40% - Bakeries

- Food industry

- Automated lines for bakery product manufacturing

- European design provides a professional and clean look

- Durable powder coating

- There is possibility to complete the line with extra components if necessary

- European components are used