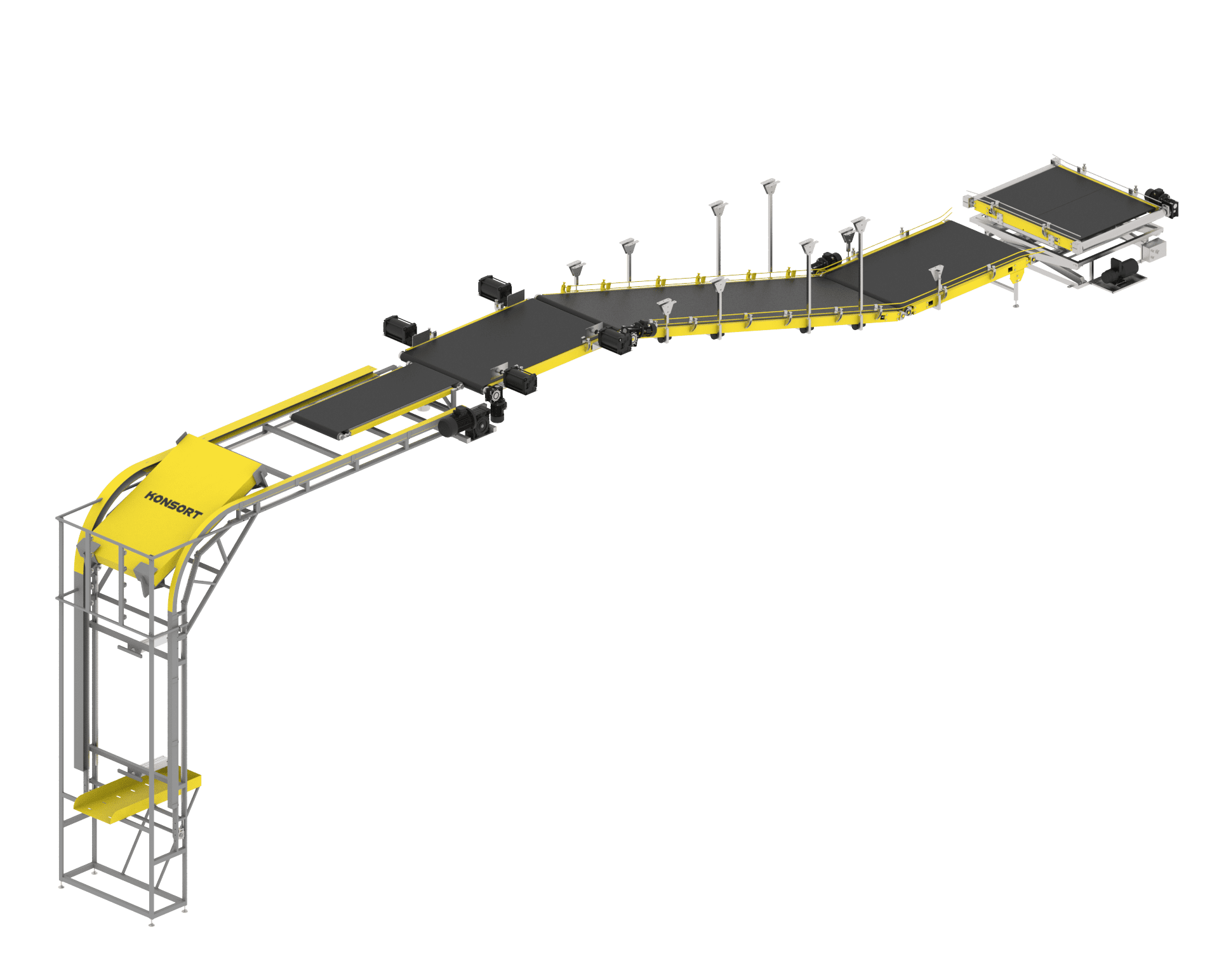

Line for door transportation and positioning

The door positioning line is represented by a system of belt conveyors. The equipment is made of structural steel with powder coating. Connection to power supply is 380 Volts. The drive is carried out by a gear motor with power from 0.55 kW to 0.75 kW. A smooth, green PVC tape is used for transportation. The line has two operating modes. At the first mode of the line operation doors are automatically received from the packaging machine. The maximum speed is 1 unit per minute. At the second mode of the line operation doors are manually delivered to the rotary lifting conveyor at a speed of no more than 1 unit per minute. The line electric control panel is on the second floor. There is a mode selection switch on the control panel – the first and the second, a line on and off button, a sound and light alarm, an intercom, a line emergency stop button with mechanical locking.

Improving in the organization of production and management by 75%

Improving in the organization of production and management by 75%  Productivity increase up to 80%

Productivity increase up to 80%  Lower production costs by 40%

Lower production costs by 40%  Reduction in human-related risks by 20%

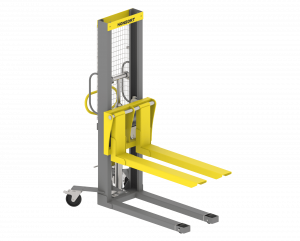

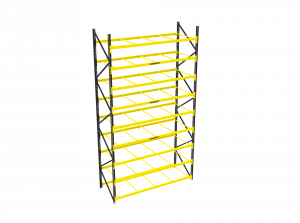

Reduction in human-related risks by 20% - To move doors along the line and their further storage

- European design provides a professional and clean look

- Durable powder coating

- There is possibility to complete the line with extra components if necessary

- Two-mode operation line

- European components are used