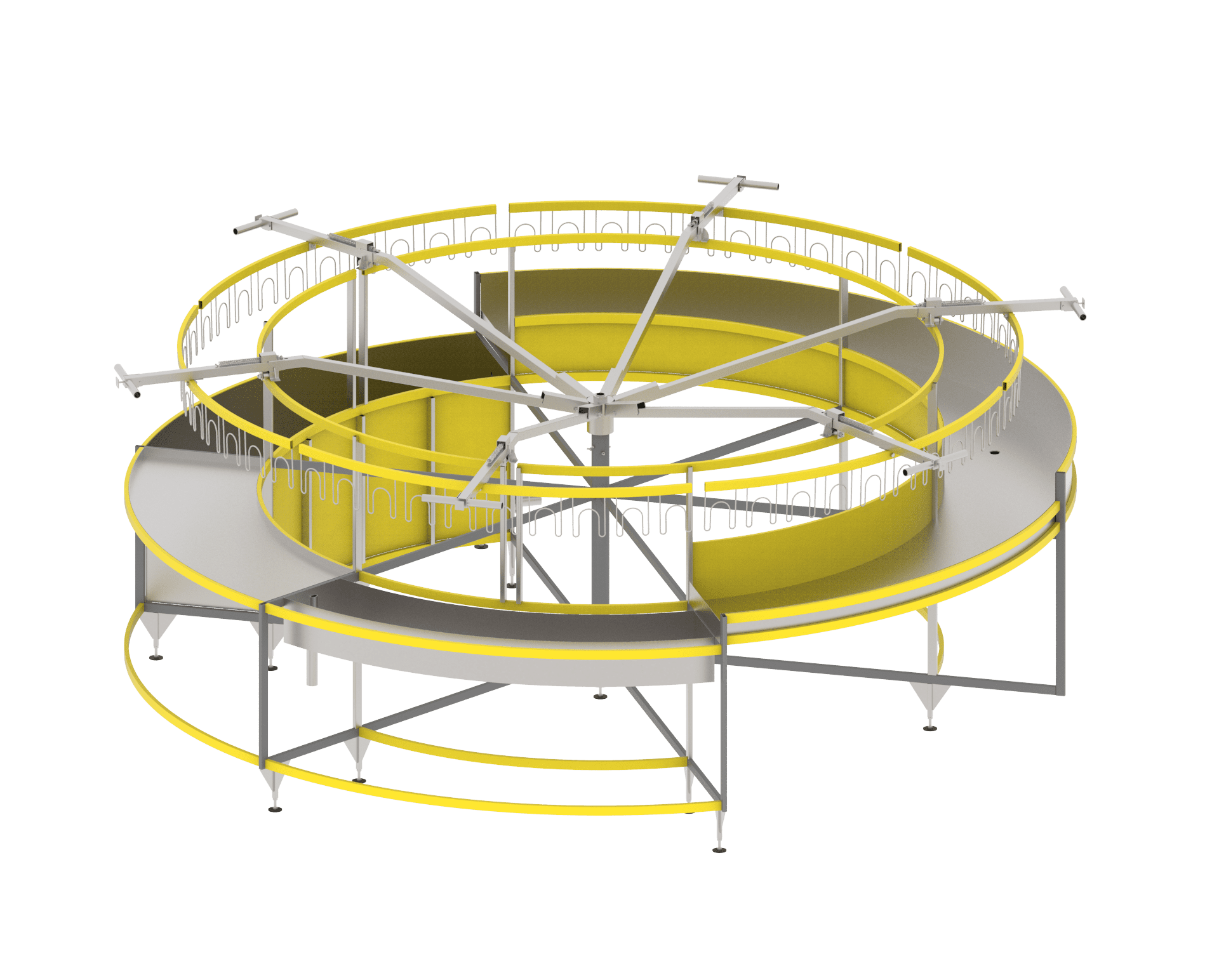

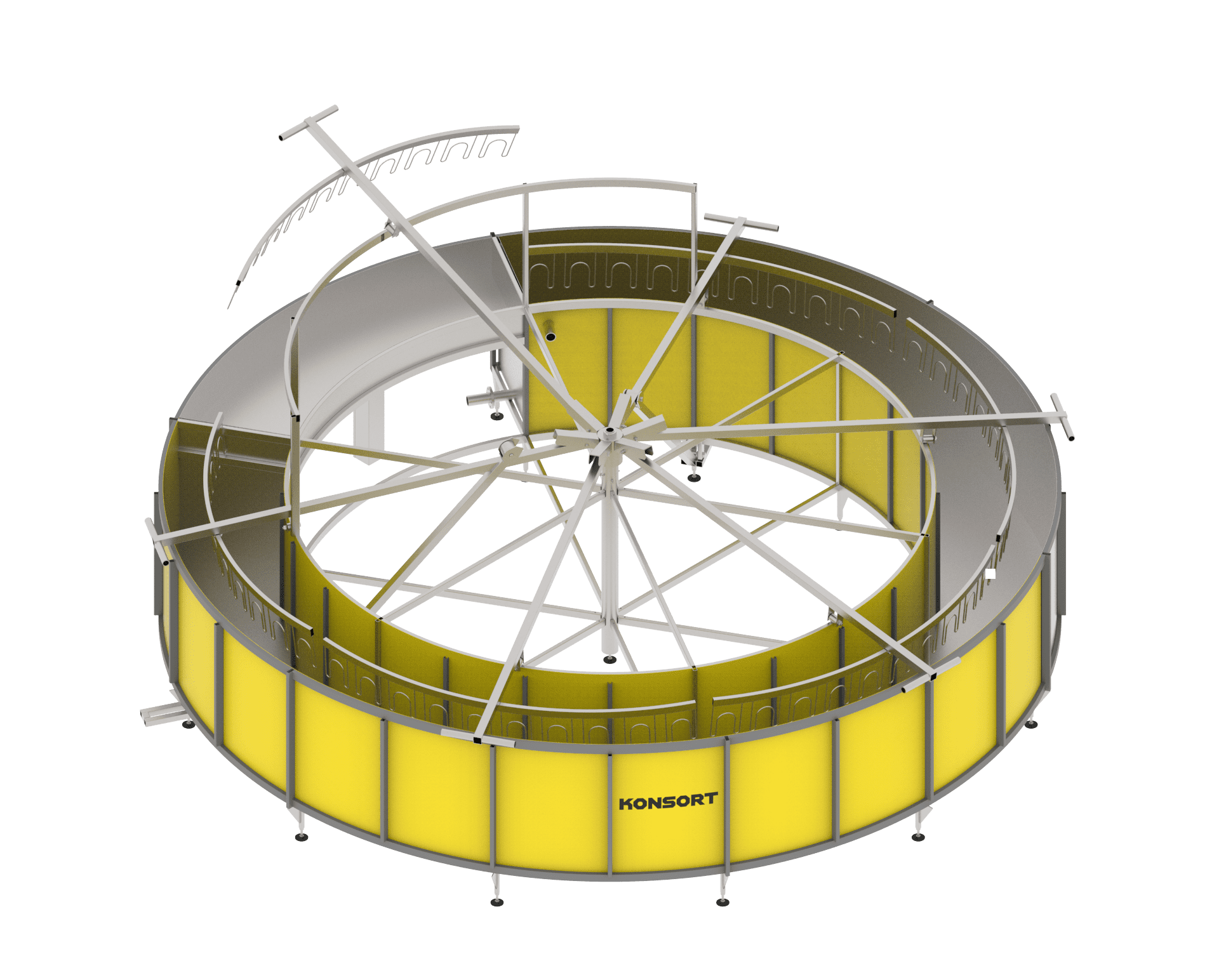

Poultry sorting and processing line

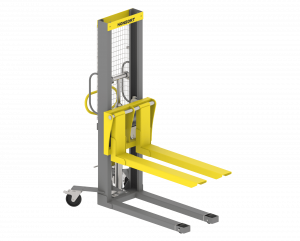

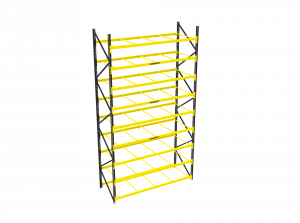

This line consists of the equipment system that is necessary for slaughtering, exsanguination, scalding, evisceration and pre-cooling of poultry. Such equipment is successfully used at chicken and poultry farms. This equipment allows electric stunning of poultry, poultry carcasses exsanguination, poultry scalding in a heat treatment bath, feather removal, poultry evisceration and cooling to a desired temperature. The equipment consists of two carousels, a centrifuge and two storage tables.

Technical characteristics:

Productivity

300-350 animals per hour

Occupied area

65-70 m2

Electricity consumption

approx. 1.3kW / h

Water consumption

3.2 m3 / h

Scalding bath capacity

0.53 m3

Cooling bath capacity

3.9 m3

Number of service staff

6-7 people

The equipment can be designed according to individual parameters necessary for the customer

Economic advantage:

Improving in the organization of production and management up to 70%

Improving in the organization of production and management up to 70%  Productivity increase up to 90%

Productivity increase up to 90%  Lower labour costs up to 50%

Lower labour costs up to 50%  Reduction in human-related risks by 20%

Reduction in human-related risks by 20%

Spheres of usage:

- To slaughter chickens, ducks, geese and quails

Benefits and options:

- European design provides a professional and clean look

- Made of certified food grade stainless steel

- There is possibility to complete the line with extra components if necessary

- Production process is automated

(UA) Про нас говорять

With these products are often ordered