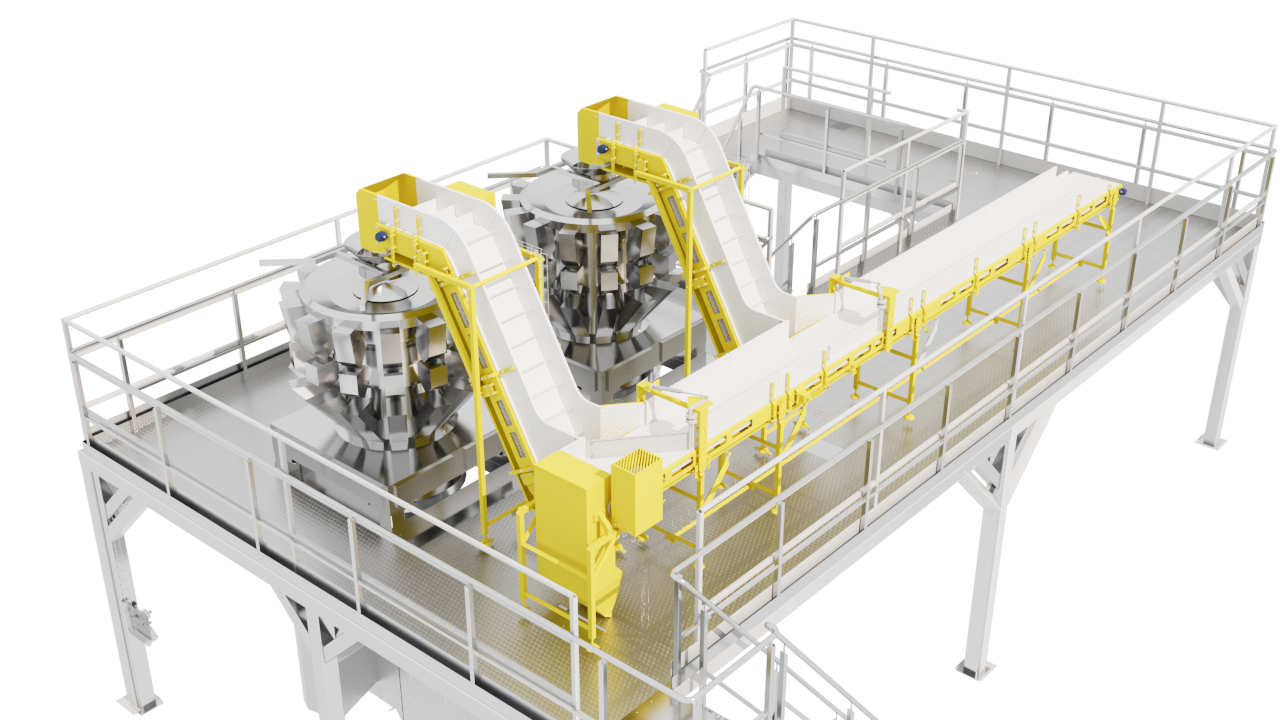

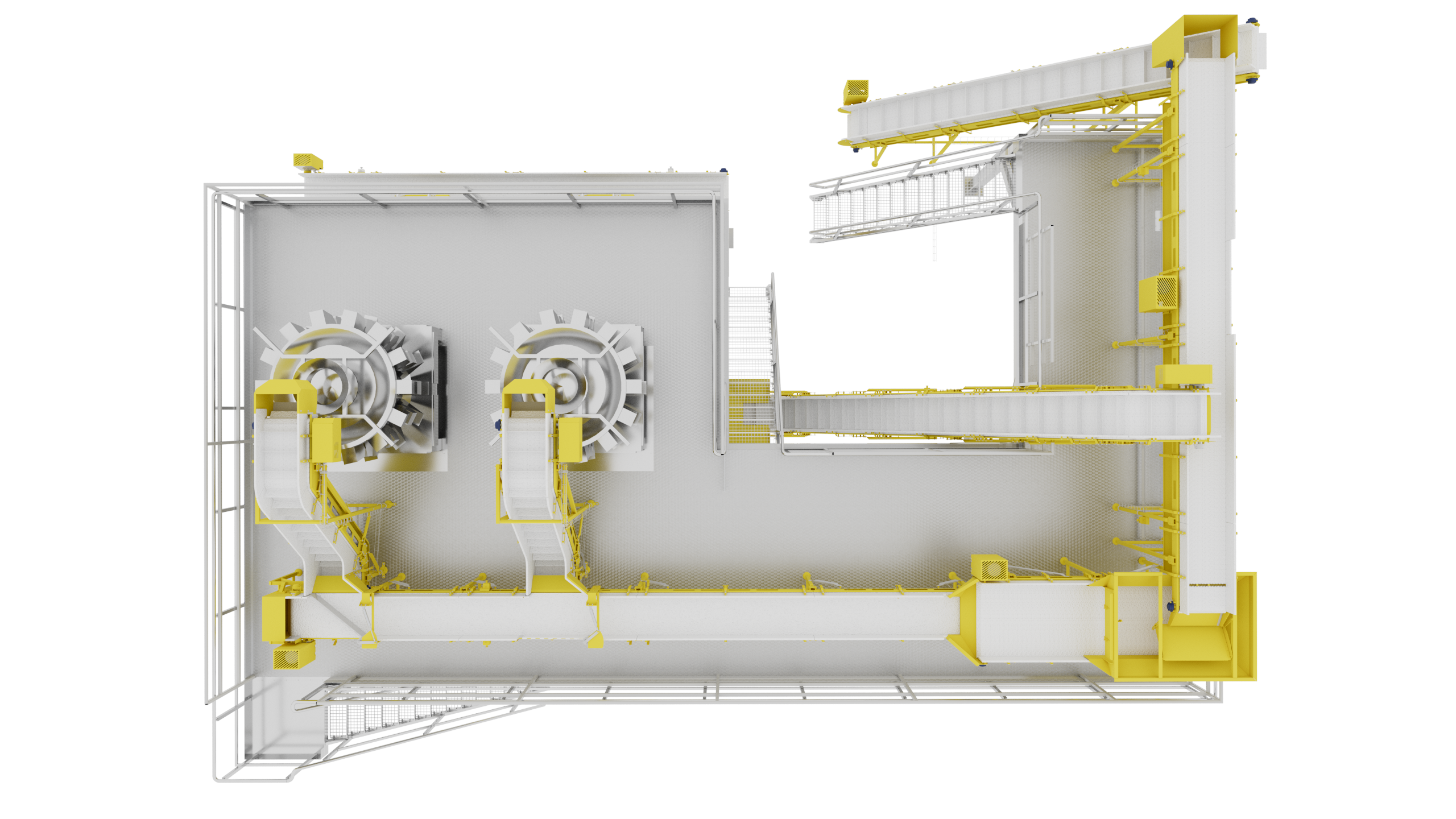

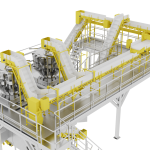

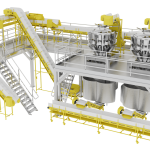

Line for semi-finished products

The universal conveyor line is designed for transportation and further packaging of meat products. The line is equipped with a programmable logic controller, where it is possible to set the logic of operation, both in manual mode (each conveyor separately) and in automatic mode (which is pre-registered in the program and automatically selects the direction of movement of products depending on the load of nodes). The line is located on the mezzanine for the possibility of free movement around the warehouse and saving space. The equipment is manufactured according to BRC food safety standards. 54R/03.2023

The line consists of:

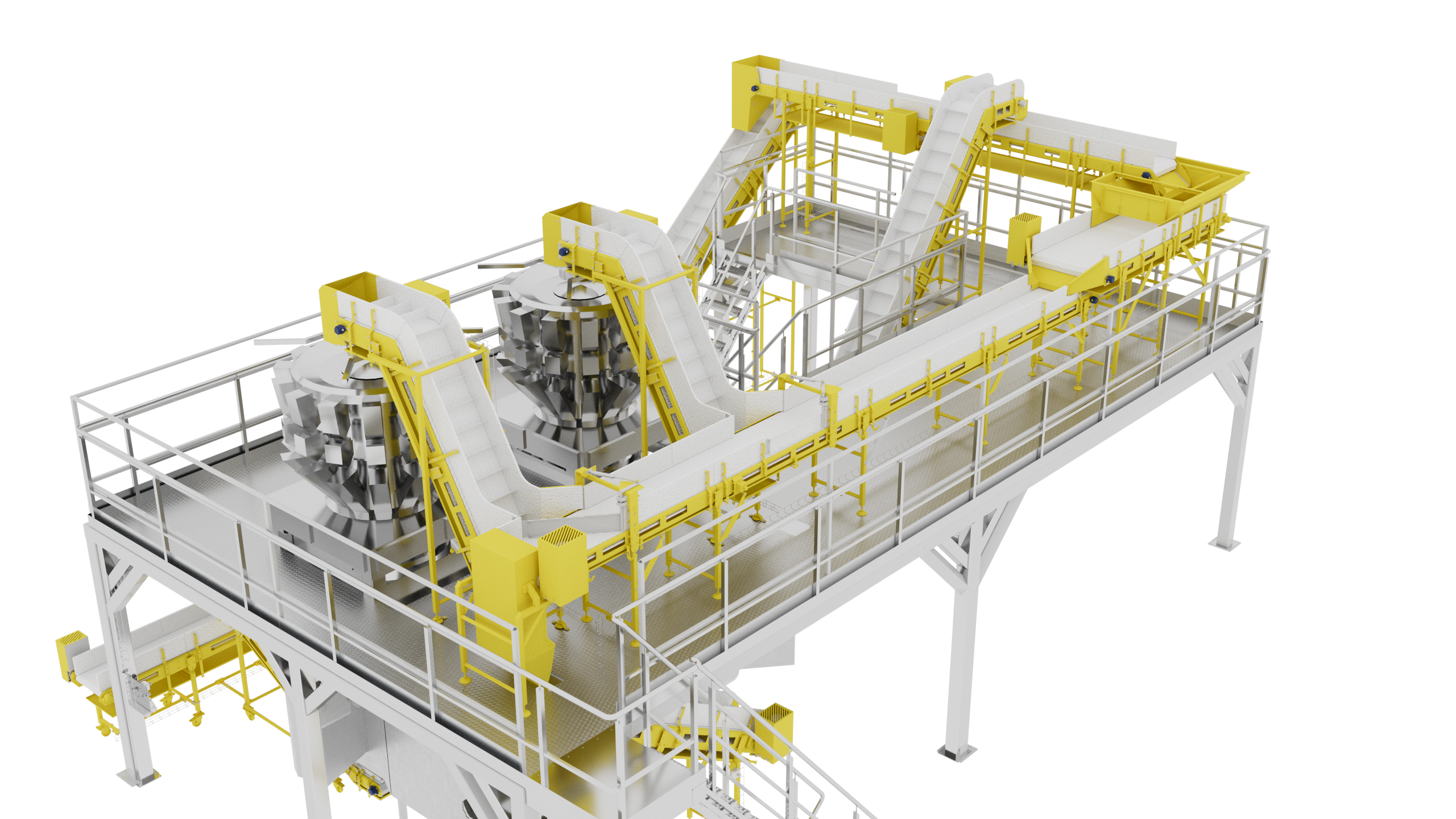

belt conveyor 7000 x 500 mm –

stationary, linear, the movement of the belt is reversible according to the signal from the sensor

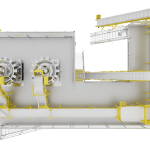

belt conveyor 2600 x 860 mm –

stationary, linear, under storage hopper for temporary storage of product

belt conveyor 8500 x 500 mm –

has two transitions for redirection to other conveyors, the flow is automatically regulated by a pneumatic damper

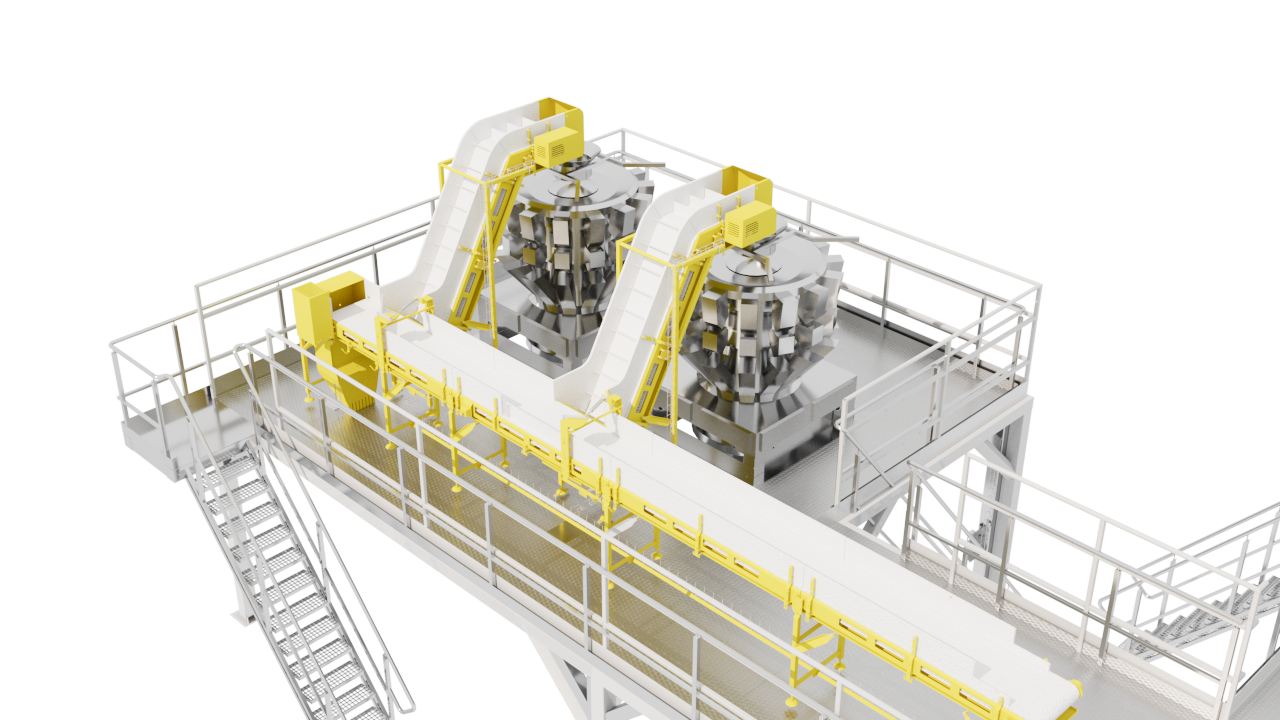

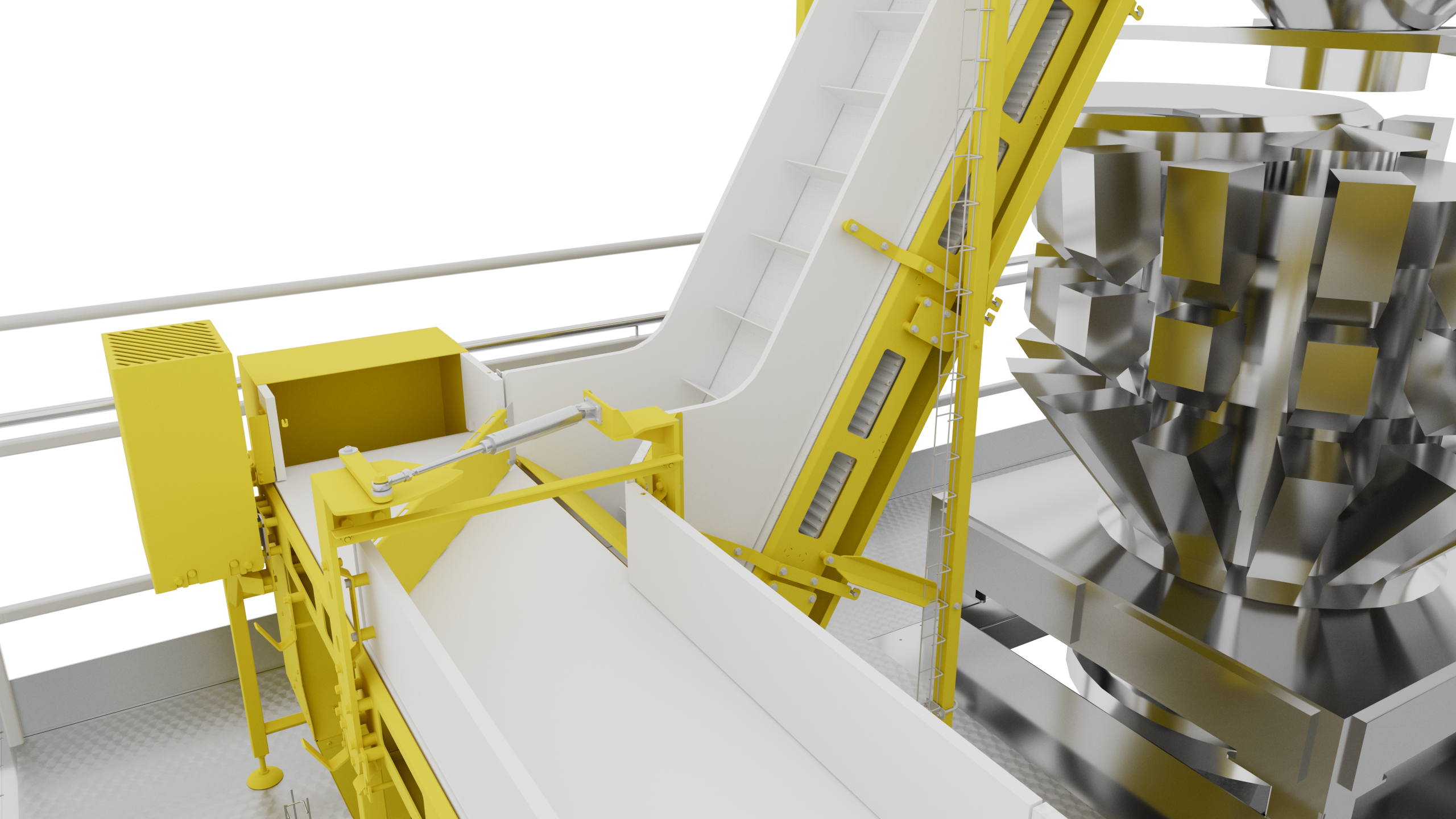

belt conveyors 2500 x 500 mm x2 -

Z-shaped, transfer the product to the vibrating conveyor of the Ishuda machine loading, works according to the sensor of the amount of product on the vibrating hopper

belt conveyor 6000 x 460 mm –

mobile, movable, wheels with polyurethane edges on a swivel fork with a brake mechanism

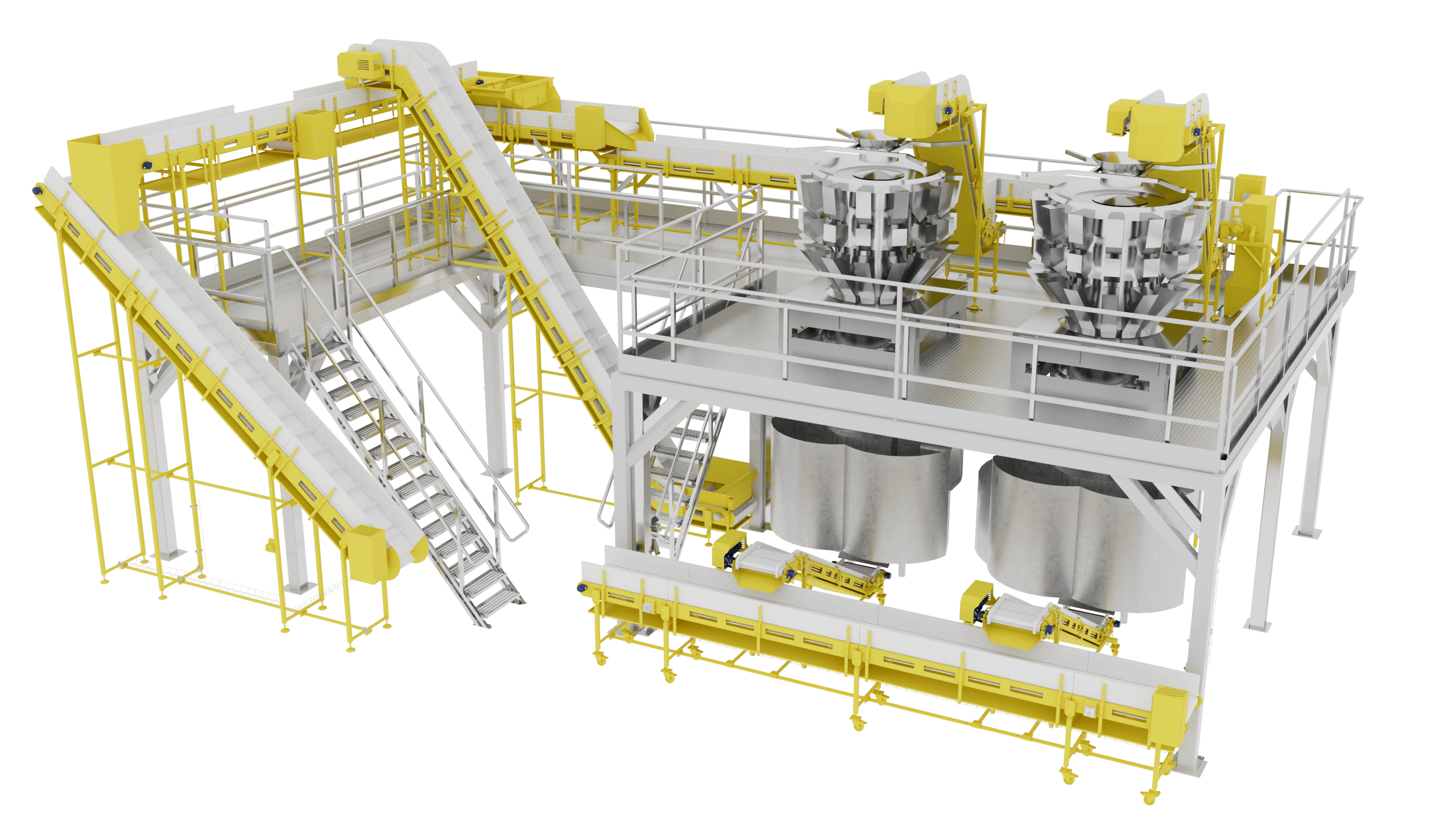

belt conveyor 4000 x 500 mm –

stationary, fixed, inclined downwards

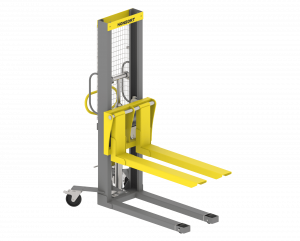

belt conveyor 5000 x 500 mm – Z-shaped, with a loading hopper, for the possibility of loading the product into the conveyor system using a mobile tipping loader

Z-shaped, with a loading hopper, for the possibility of loading the product into the conveyor system using a mobile tipping loader

belt conveyor 3000 x 500 mm –

stationary, fixed, inclined downwards

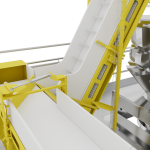

belt conveyors 1500 x 490 mm –

Z-shaped, movable, wheels with a polyurethane edge, on a swivel fork, with a brake mechanism, feed the product to another conveyor.

Economic advantage:

Improving in the organization of production and management by 65%

Improving in the organization of production and management by 65%  Productivity increase up to 60%

Productivity increase up to 60%  Lower labour costs by 78%

Lower labour costs by 78%  Reduction in human-related risks by 40%

Reduction in human-related risks by 40%

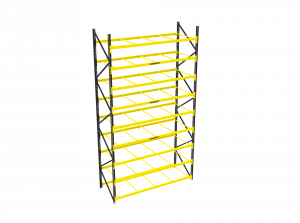

Spheres of usage:

- Pharmaceutical companies

- Enterprises specializing in sugar and coffee production

Benefits and options:

- European design provides a professional and clean look

- Durable powder coating

- There is possibility to complete the line with extra components if necessary

- European components are used

(UA) Про нас говорять

With these products are often ordered