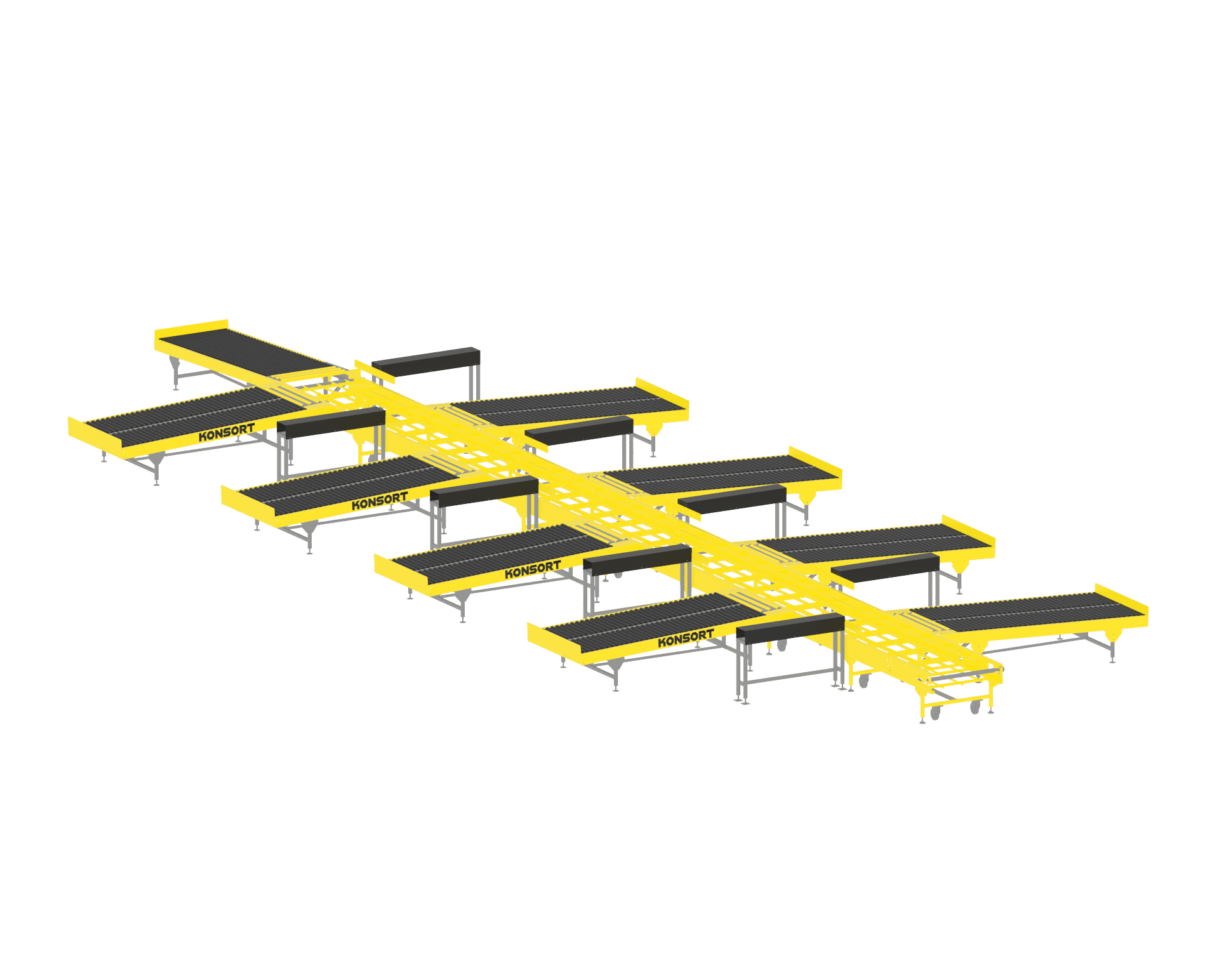

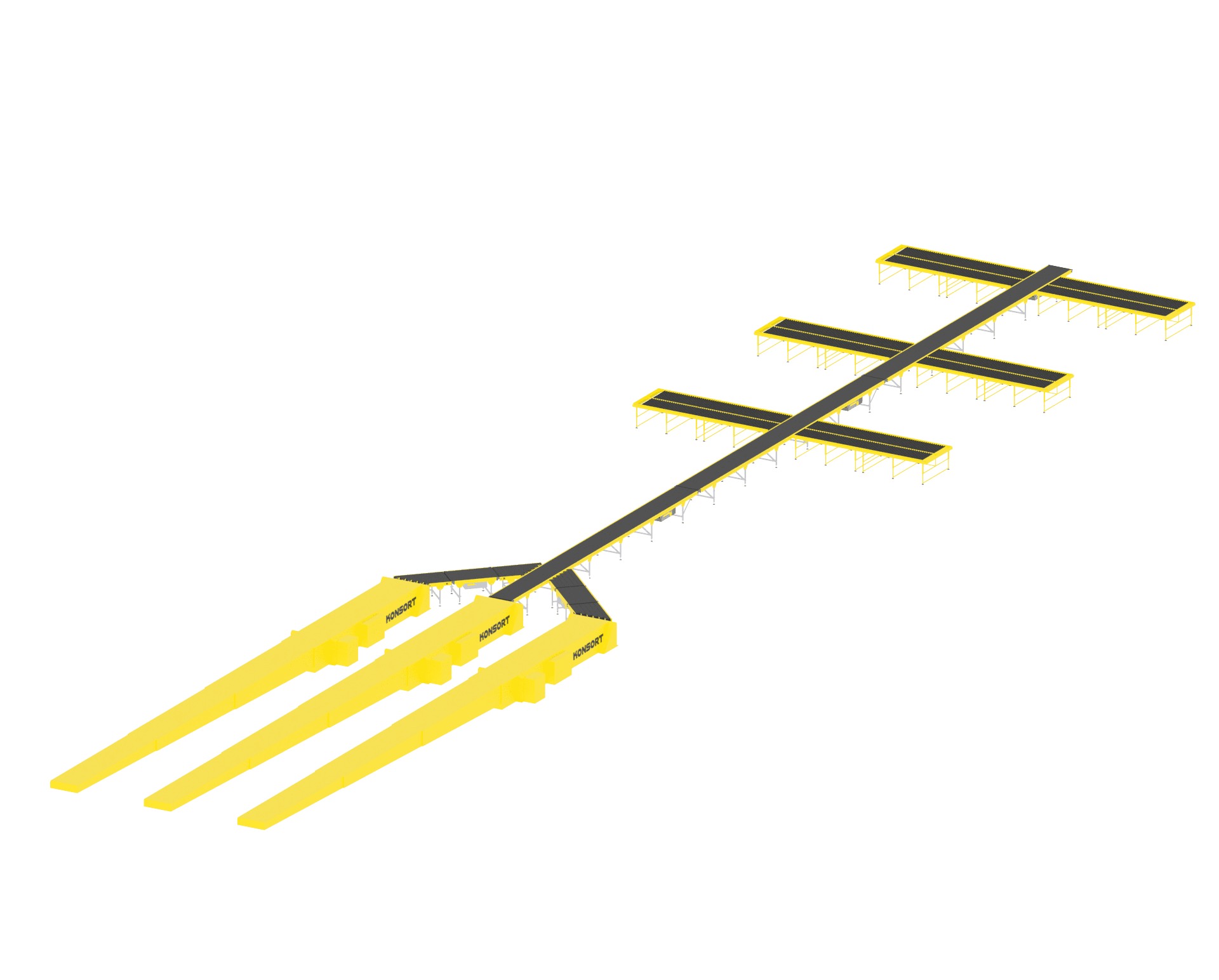

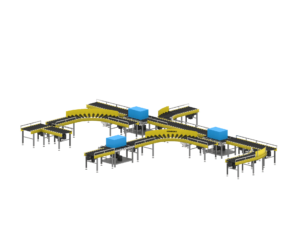

With the help of the equipment included in the lines for oversize cargo our customers receive ready-made solutions for logistic enterprises and warehouses.

Saving time;

Jobs reduction;

Fast and accurate loads distribution by size and direction;

Clear and understandable load distribution;

Cargo distribution process automation;

Reliability and guarantee.

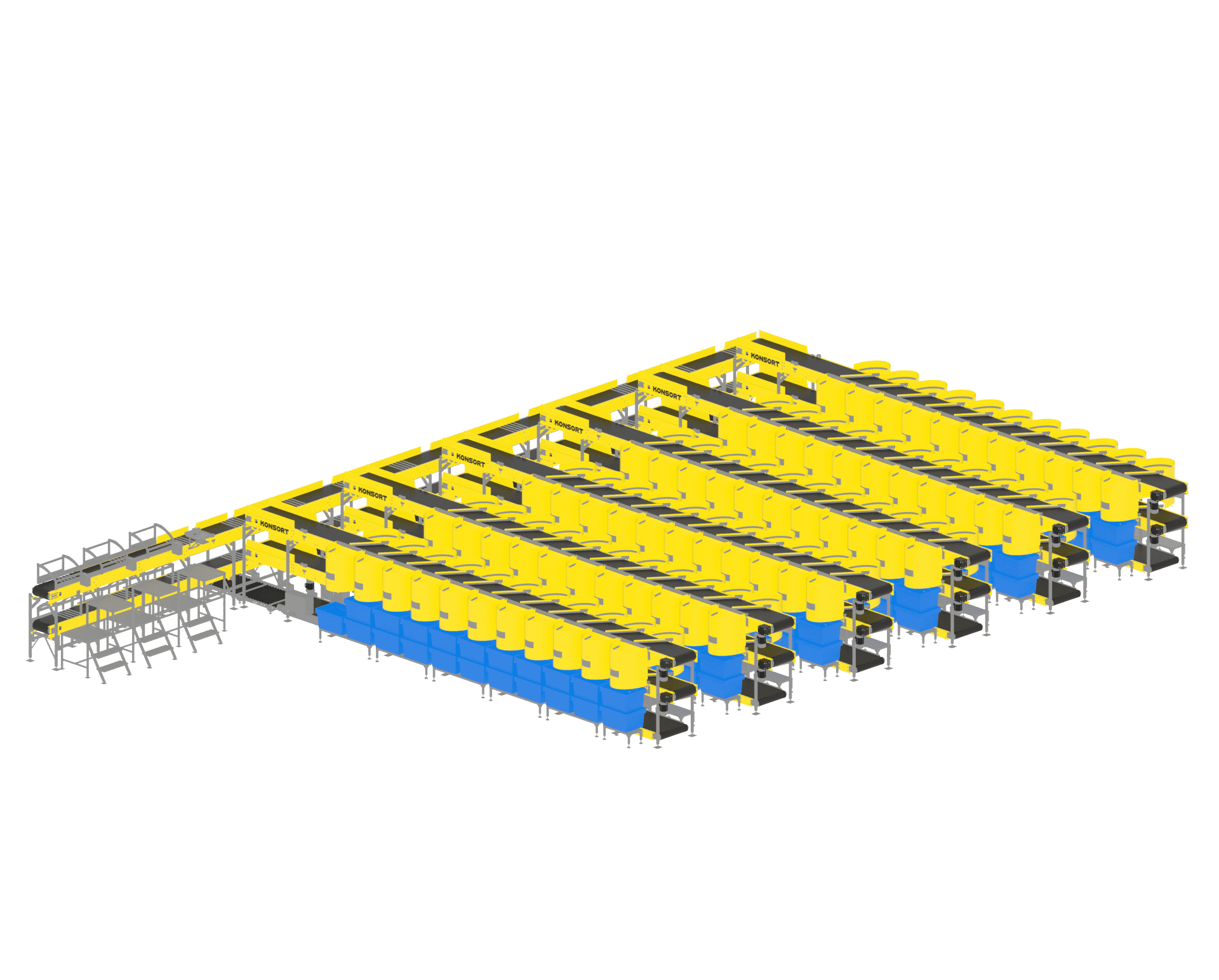

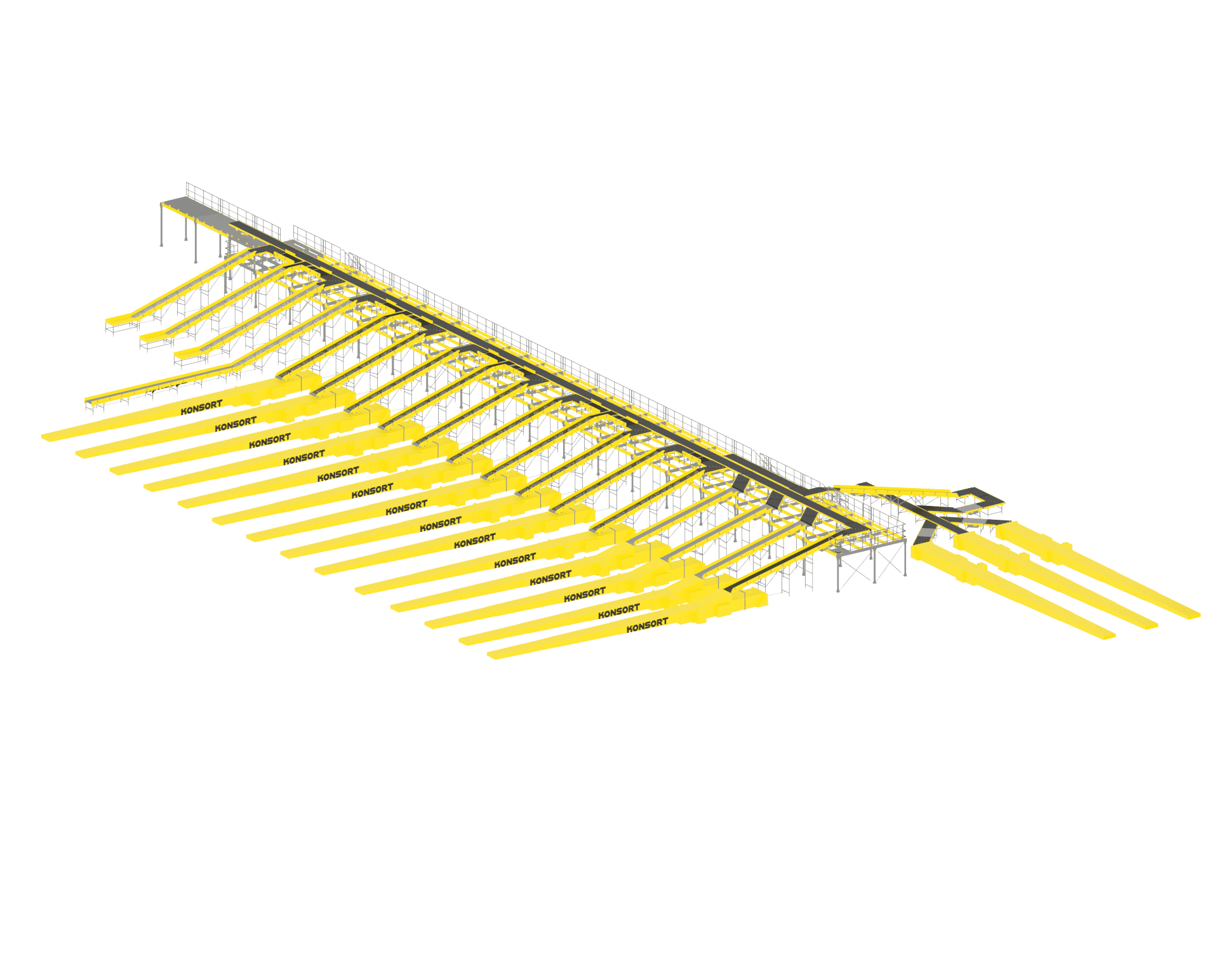

Correctly built logistics can reduce costs several times and significantly reduce product cost. Our small cargo line will help customers with sorting cargo up to 10 kg.

Space saving as the equipment can be placed in two levels;

Solves the issue of various dimensions cargo sorting;

Distribution of goods to 120 directions;

Accurate distribution of goods using unique automation solutions;

Dumping cargo using automation;

Productivity is 3 600 loads per hour.

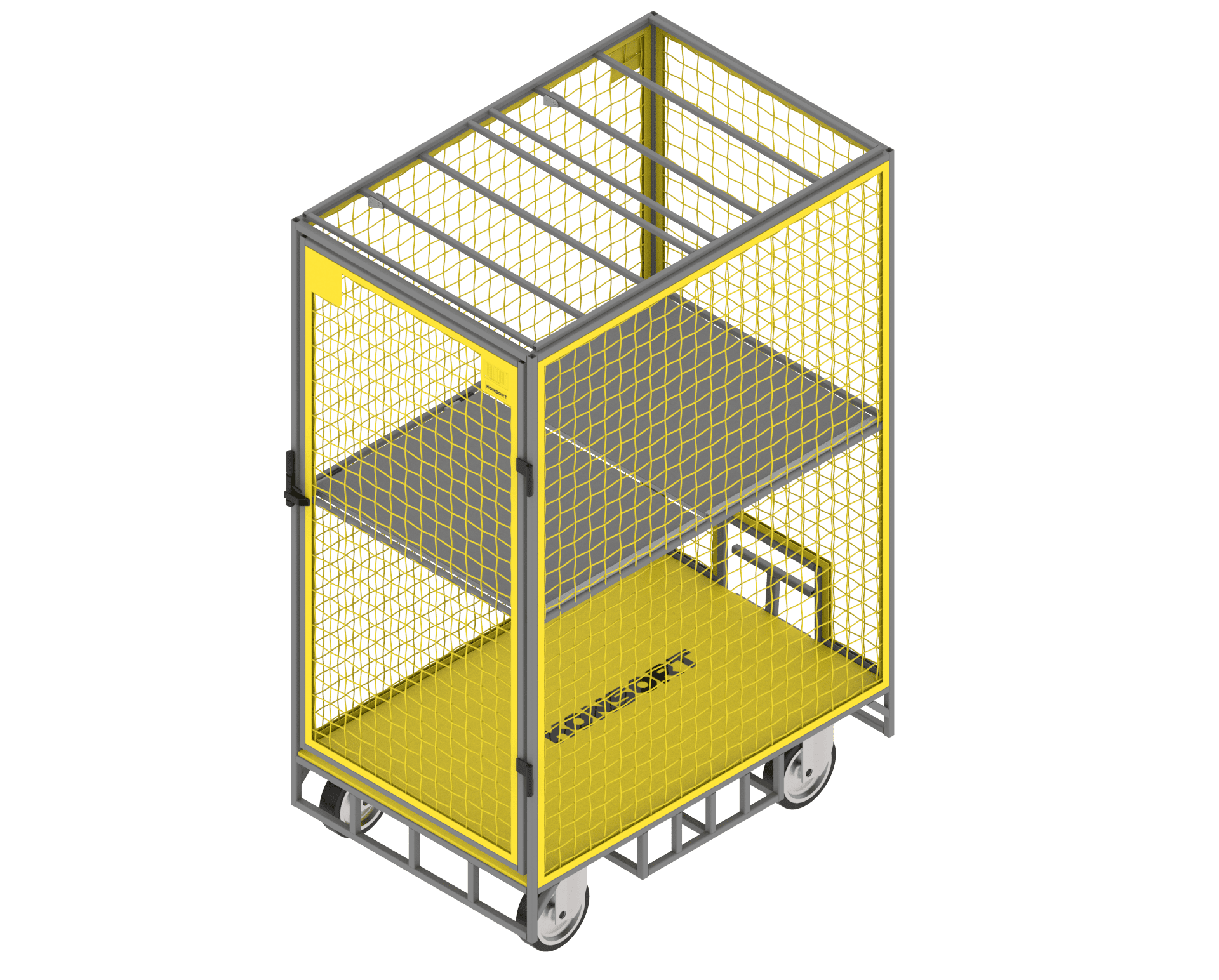

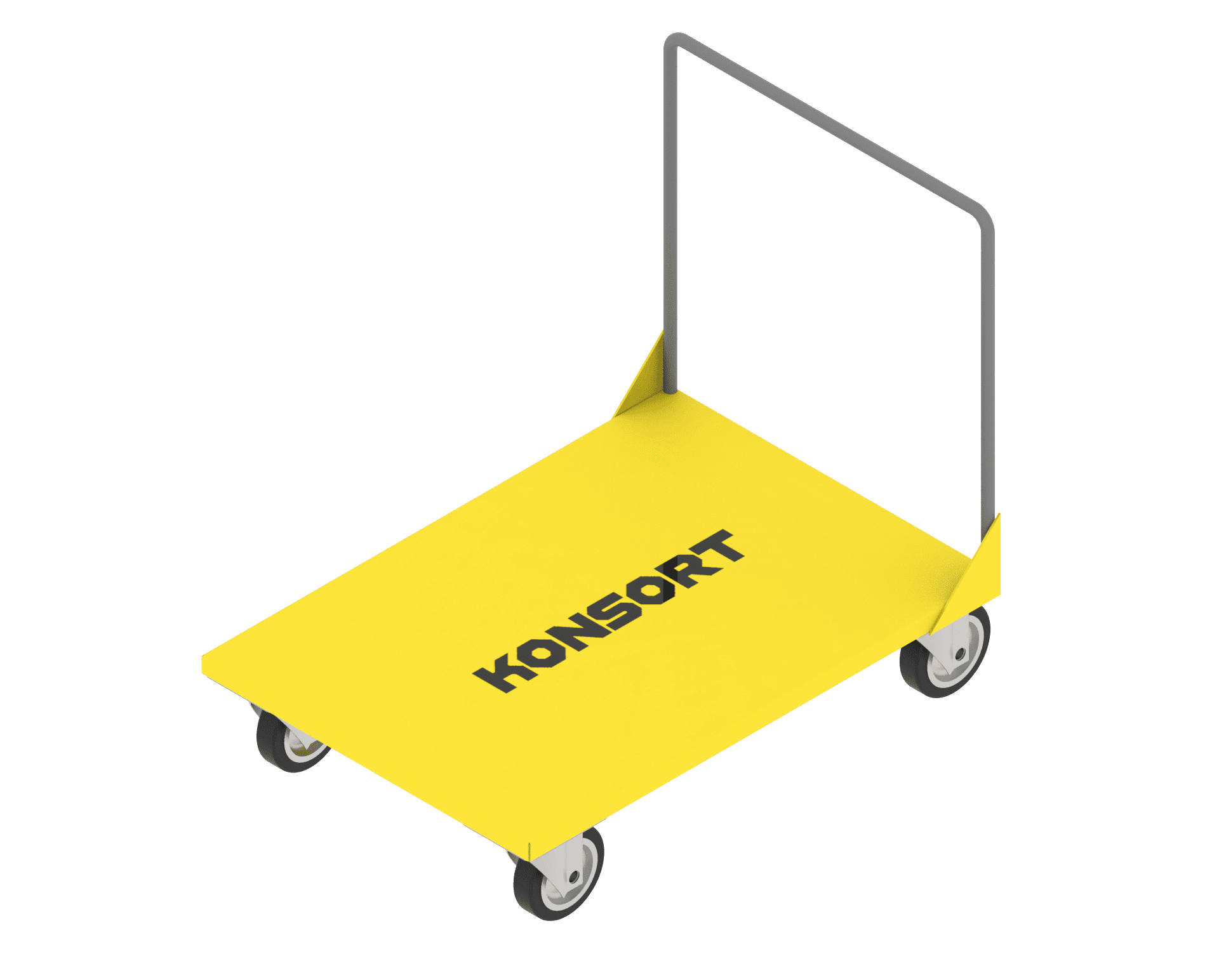

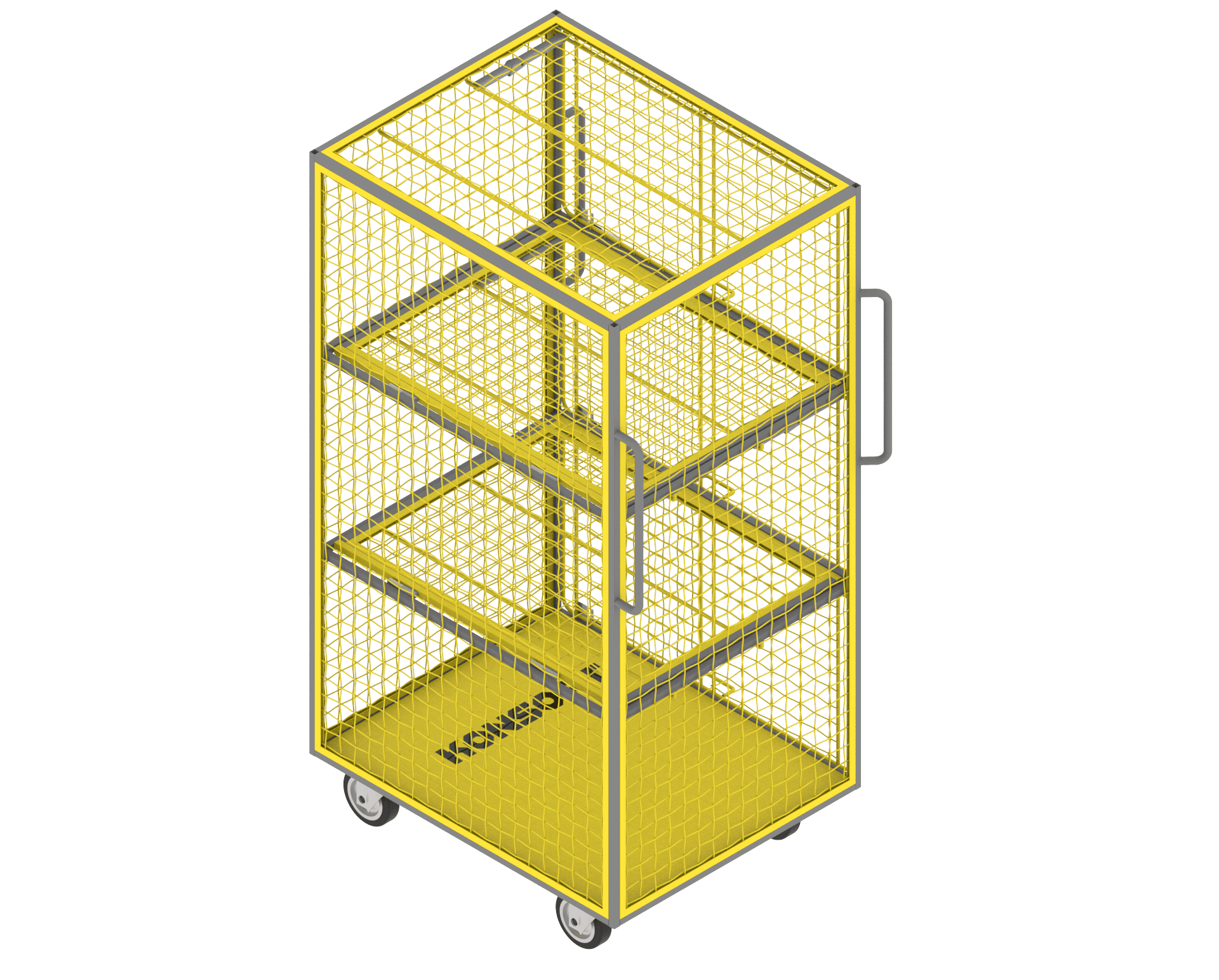

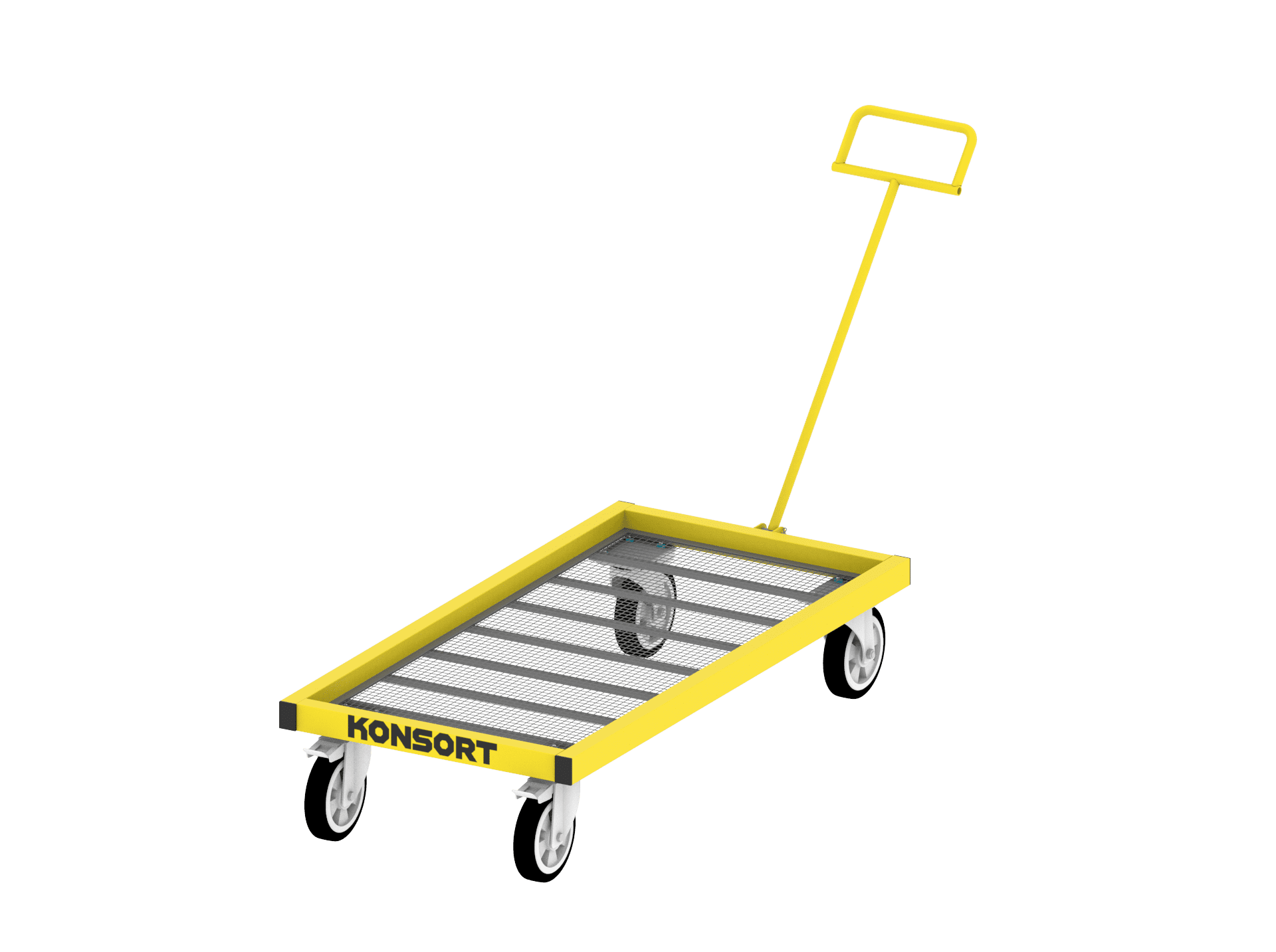

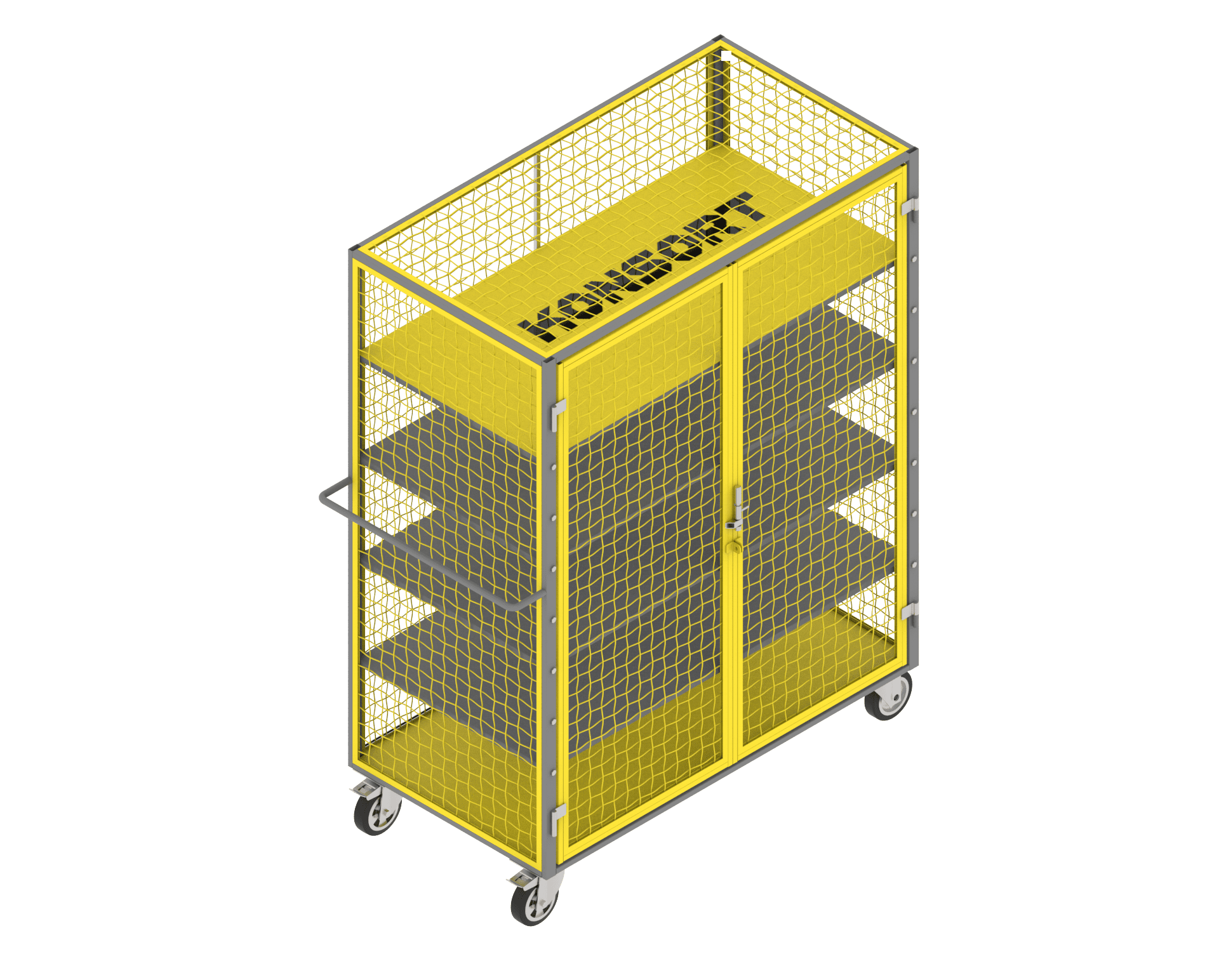

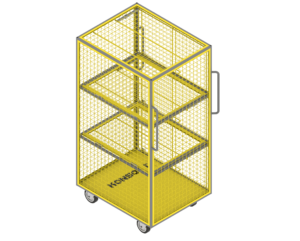

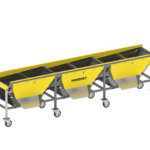

Carts are exactly the kind of equipment that will help enterprises with their warehouses to maximize speed of goods delivery to the sorting line or make it simpler to move around the warehouse.

Wide range variety;

Facilitate manual labor;

Dimensions change according to the customer wishes;

Small turning radius;

Energy saving.

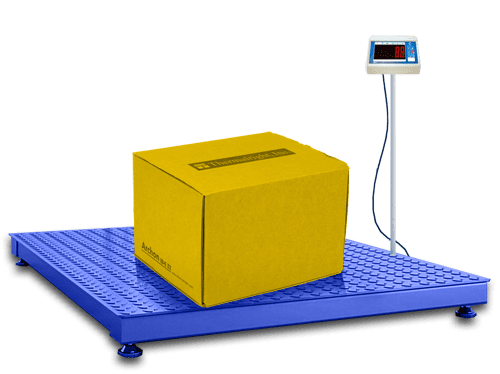

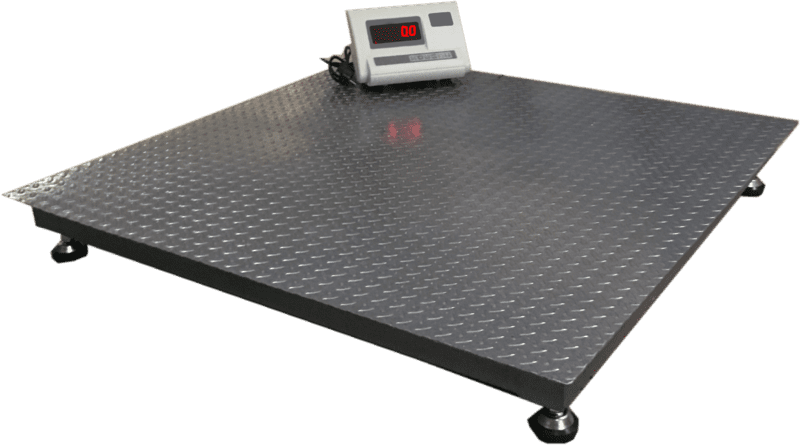

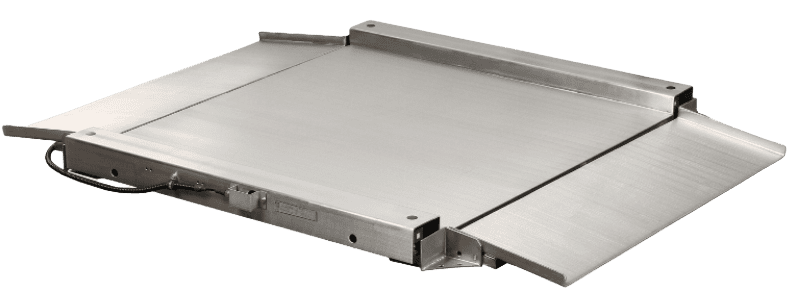

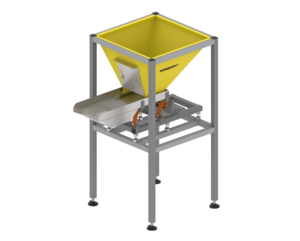

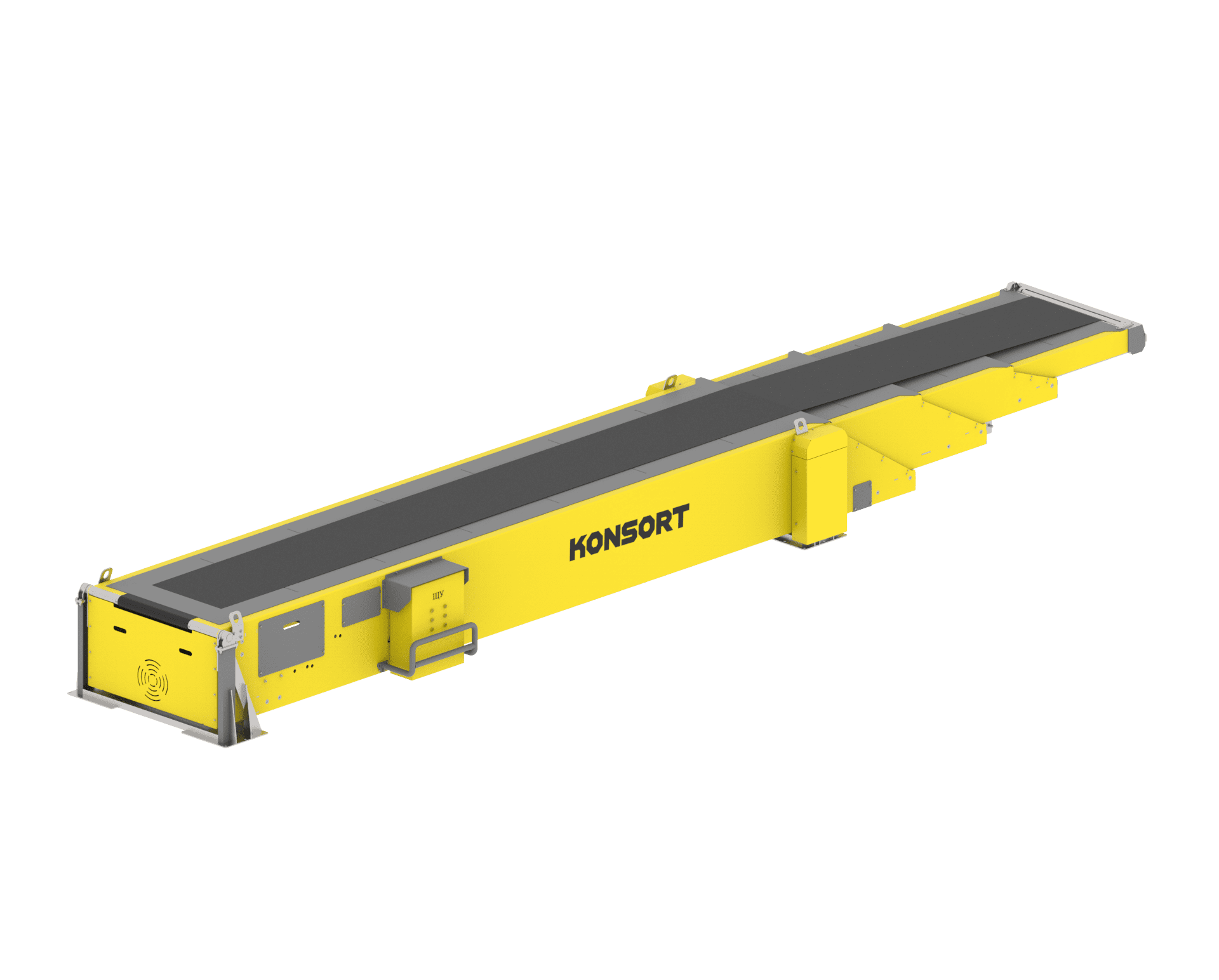

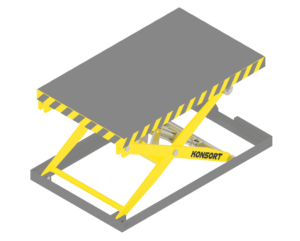

For customers, who are specialized in warehousing, weight goods and raw materials movement, weighing equipment will be irreplaceable. Without destroying but complementing the business process our equipment can be easily assembled into your technological chain and will increase its efficiency.

Weighing of any loads (according to the scale model choice);

Weighing and transportation (pallet truck scales);

Increase in warehouse throughput;

Easy to operate;

Overload protection;

Increasing the cargo acceptance process efficiency by 80%.

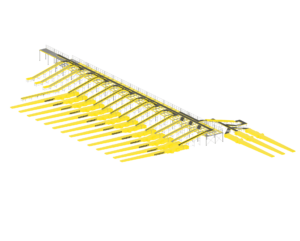

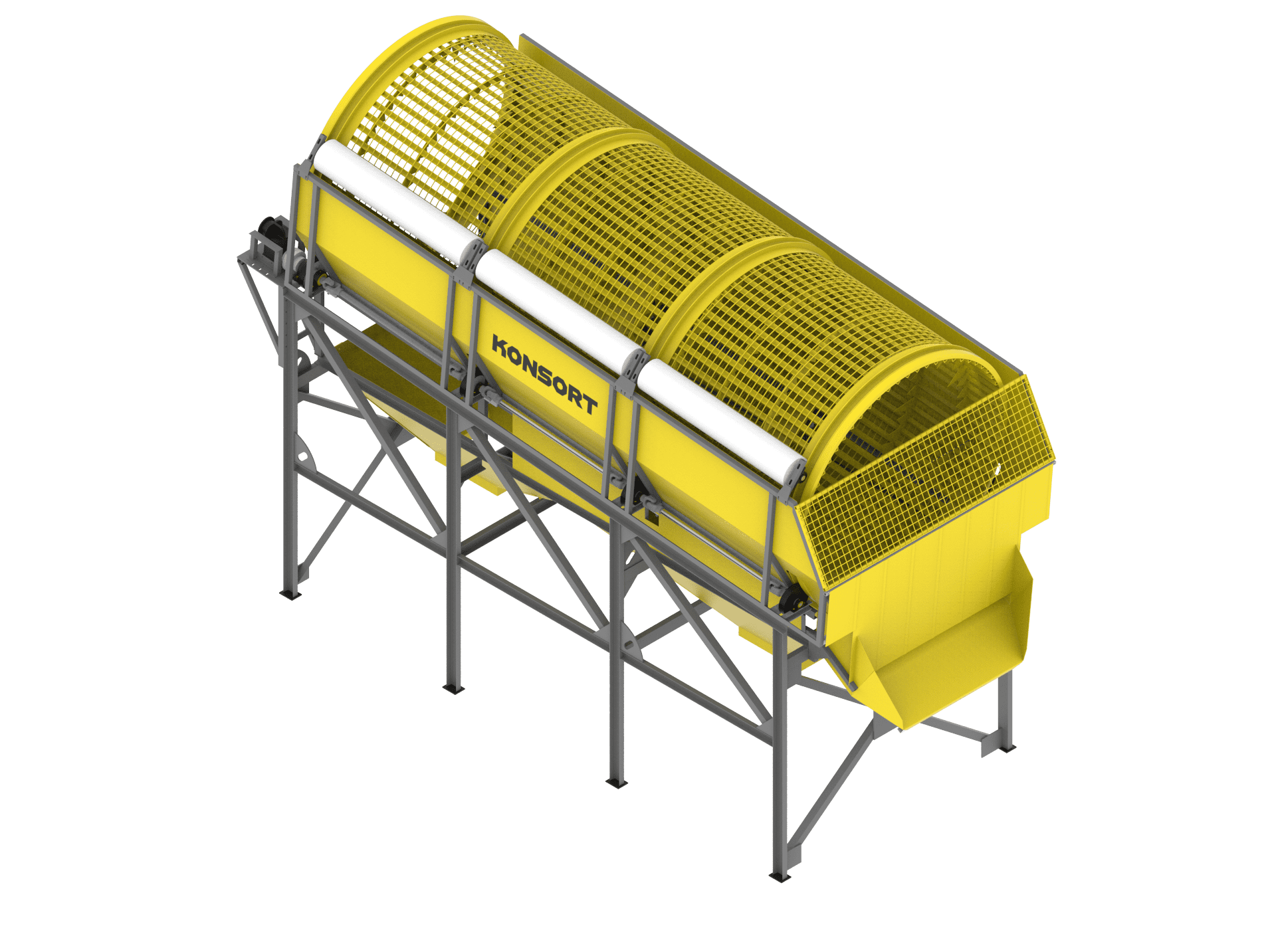

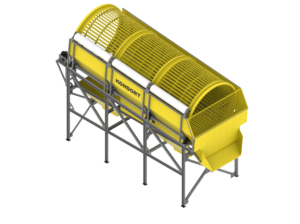

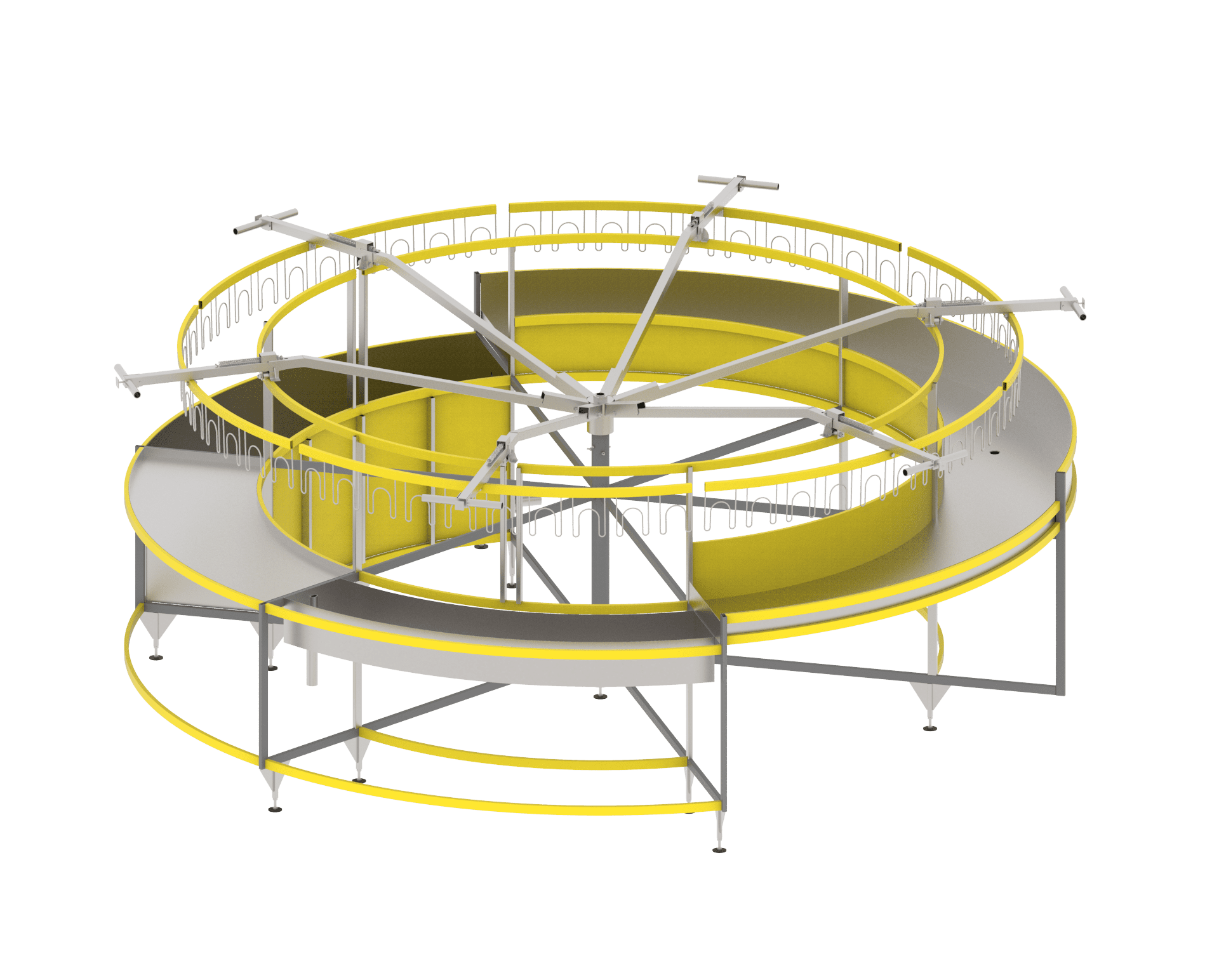

With the help of various modification calibrators it becomes possible to sort your products by size. Depending on their size they will get into different factions you need.

Saving time;

- Increase in production productivity;

- Production process automation;

- Technological process systematization;

- Manual labor facilitation;

- Precise sorting of agricultural enterprises processing products, and accordingly improving the quality.

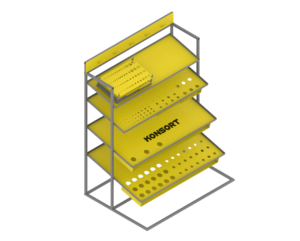

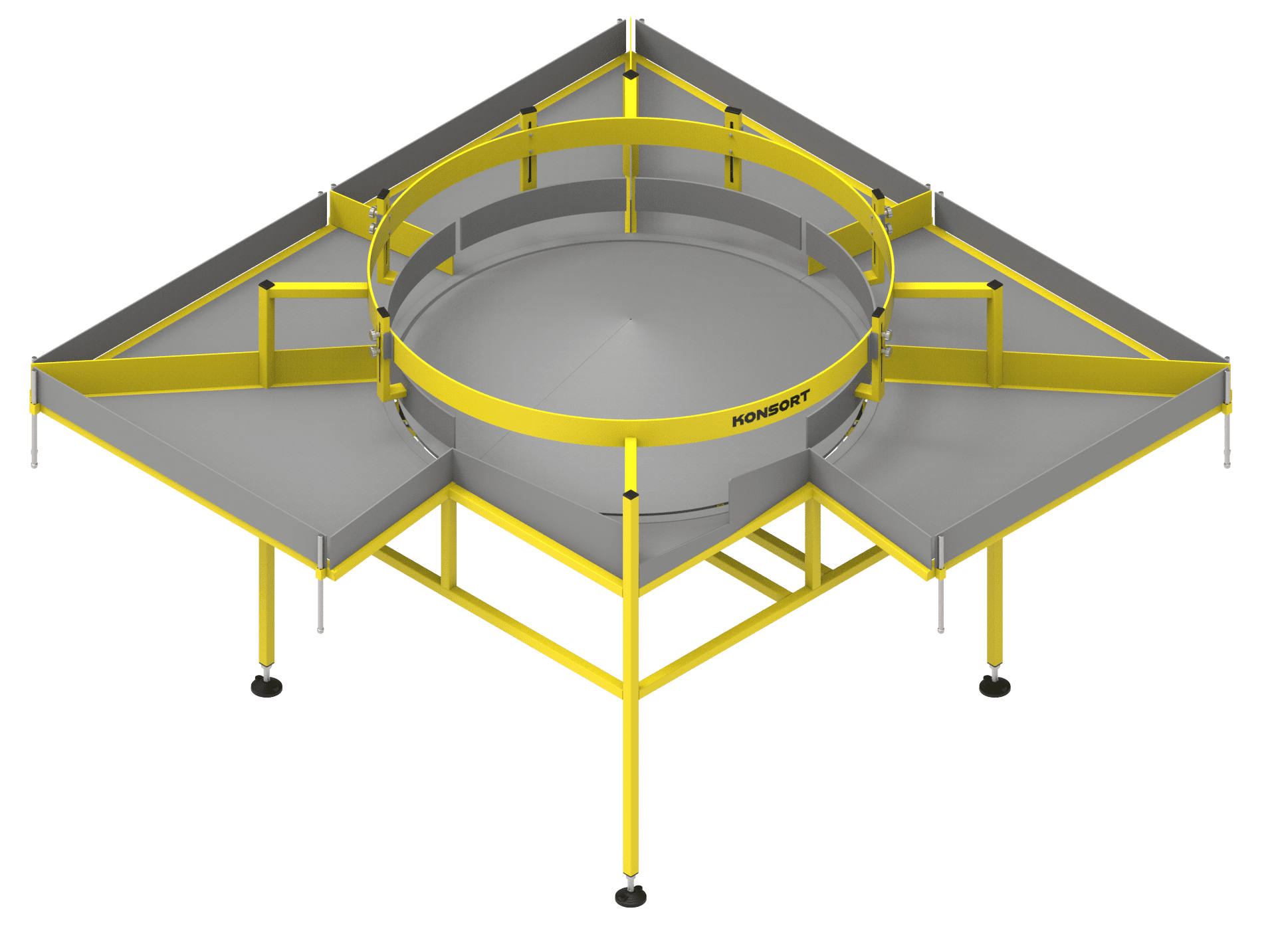

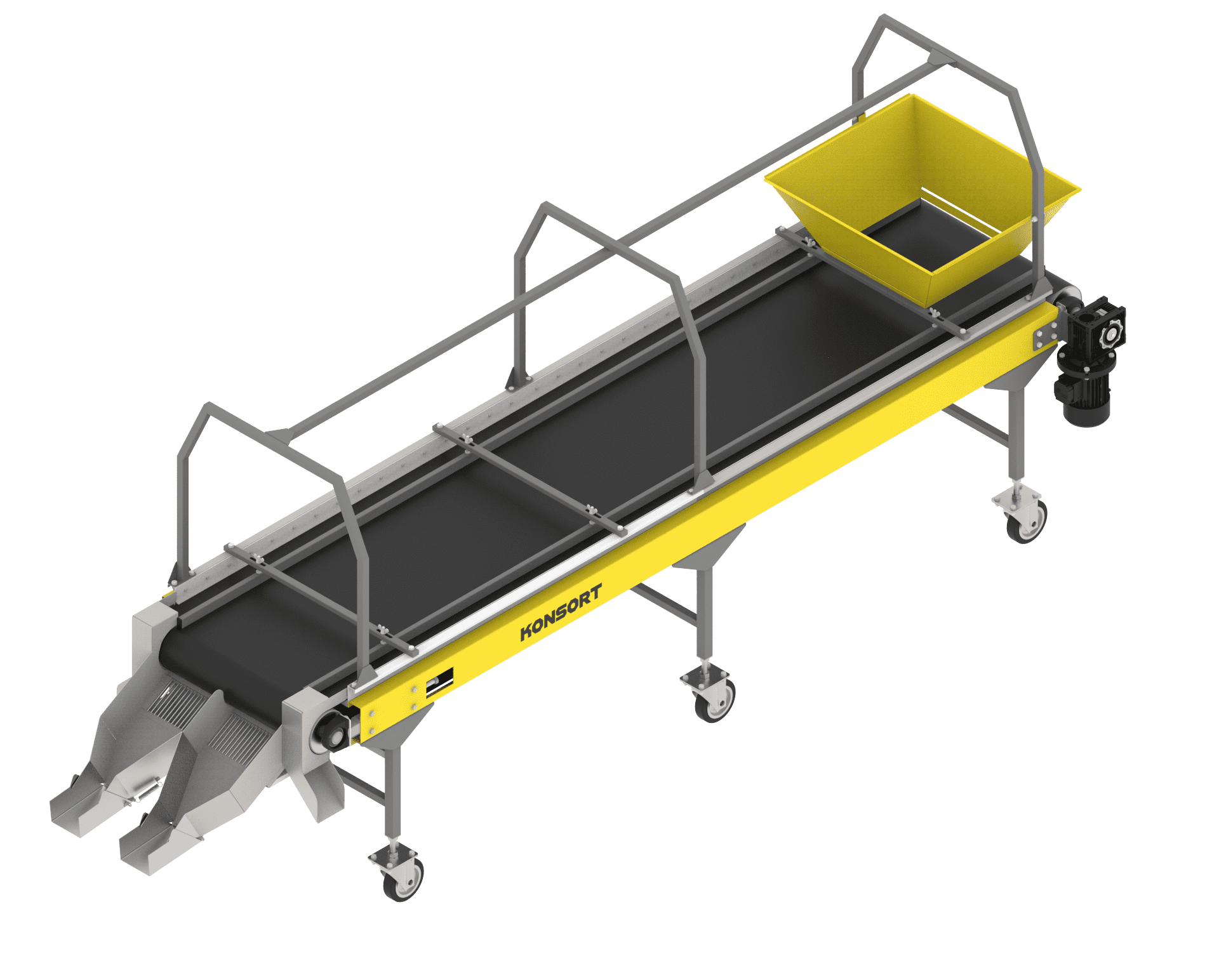

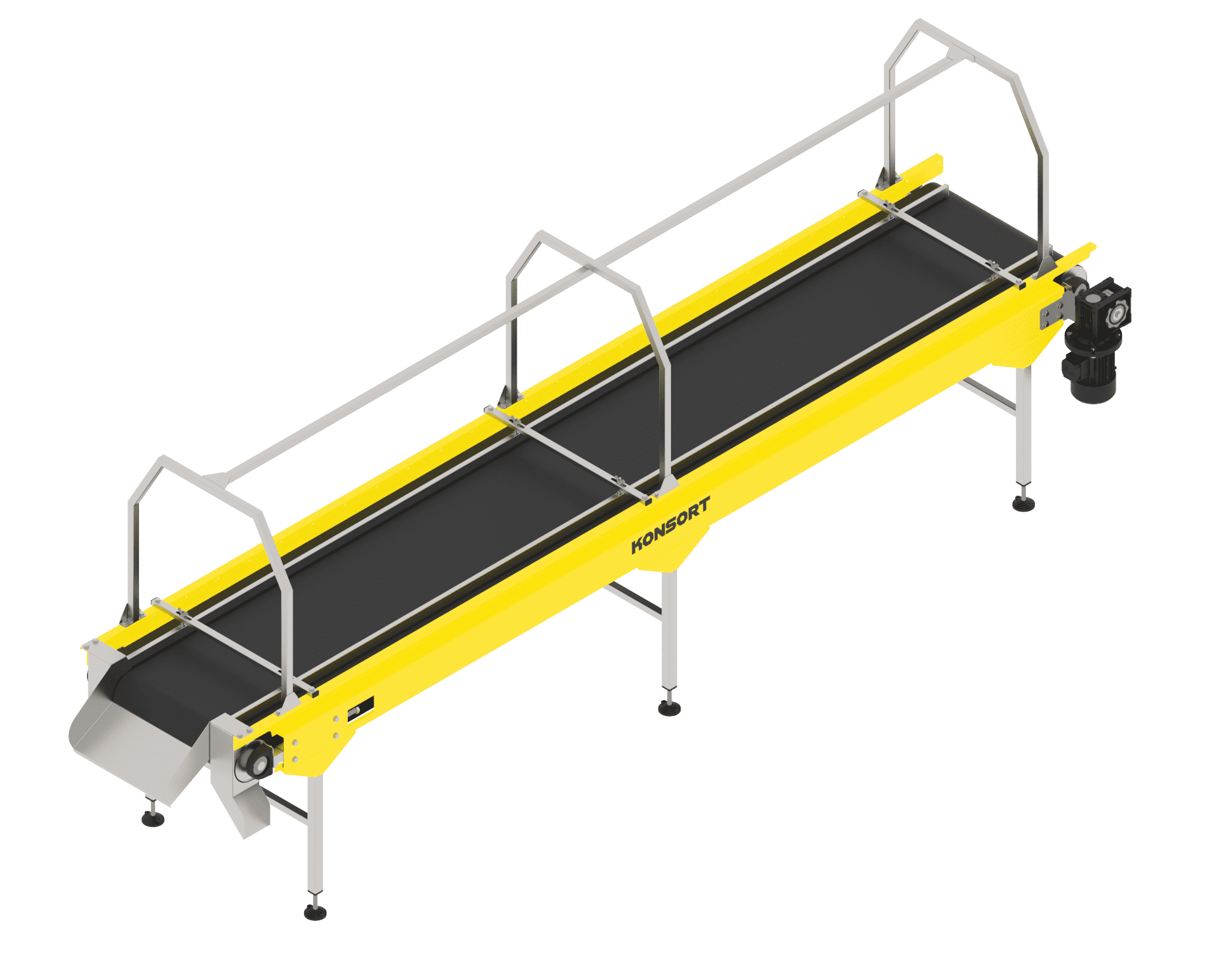

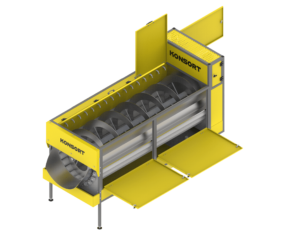

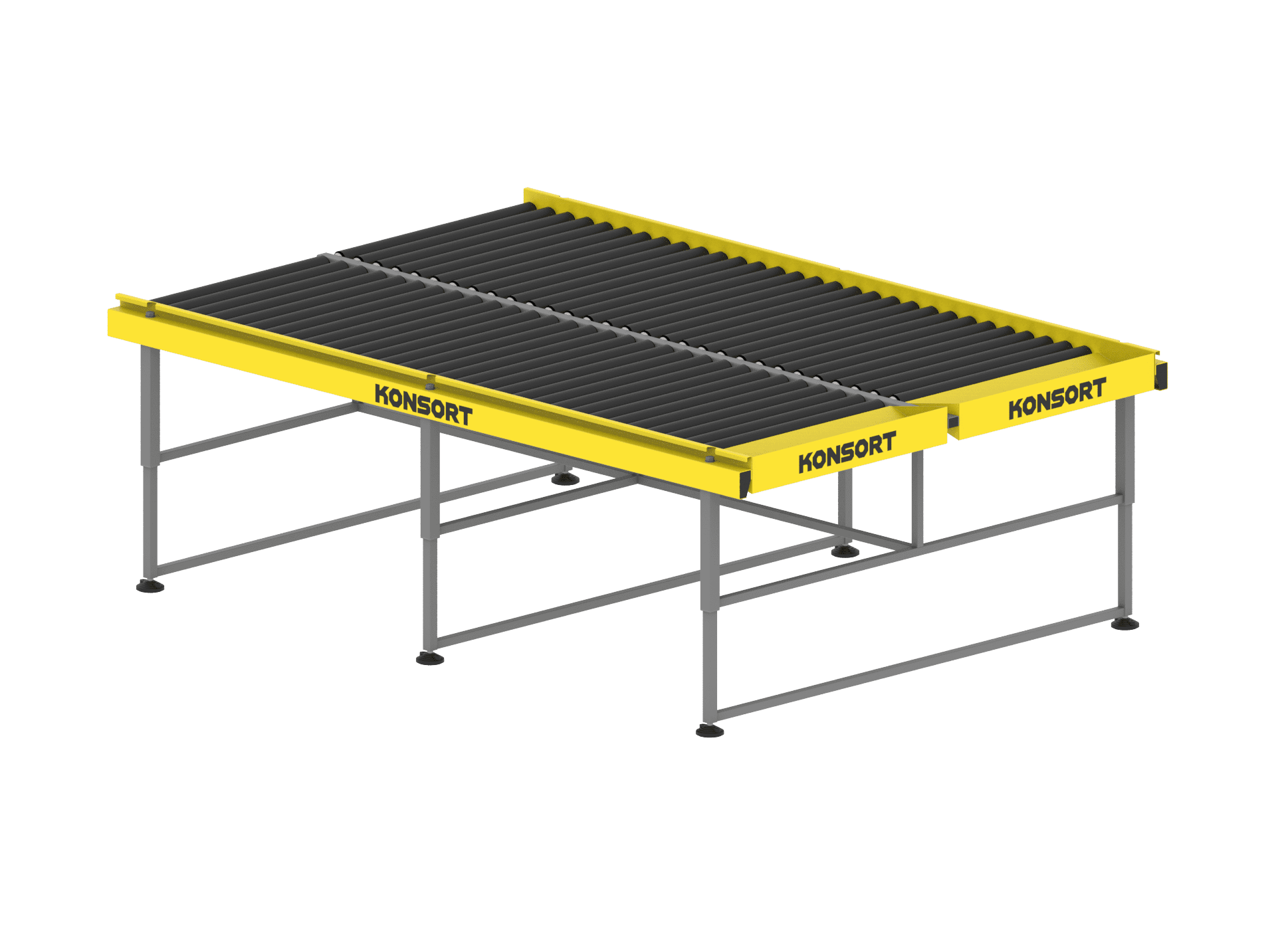

Convenience at the stage of products primary processing – an inspection sorting table is designed for quality control and raw materials sorting.

Production process mechanization;

- Increased processing speed;

- Product damage minimization;

- Final product quality improving;

- Increase in productivity.

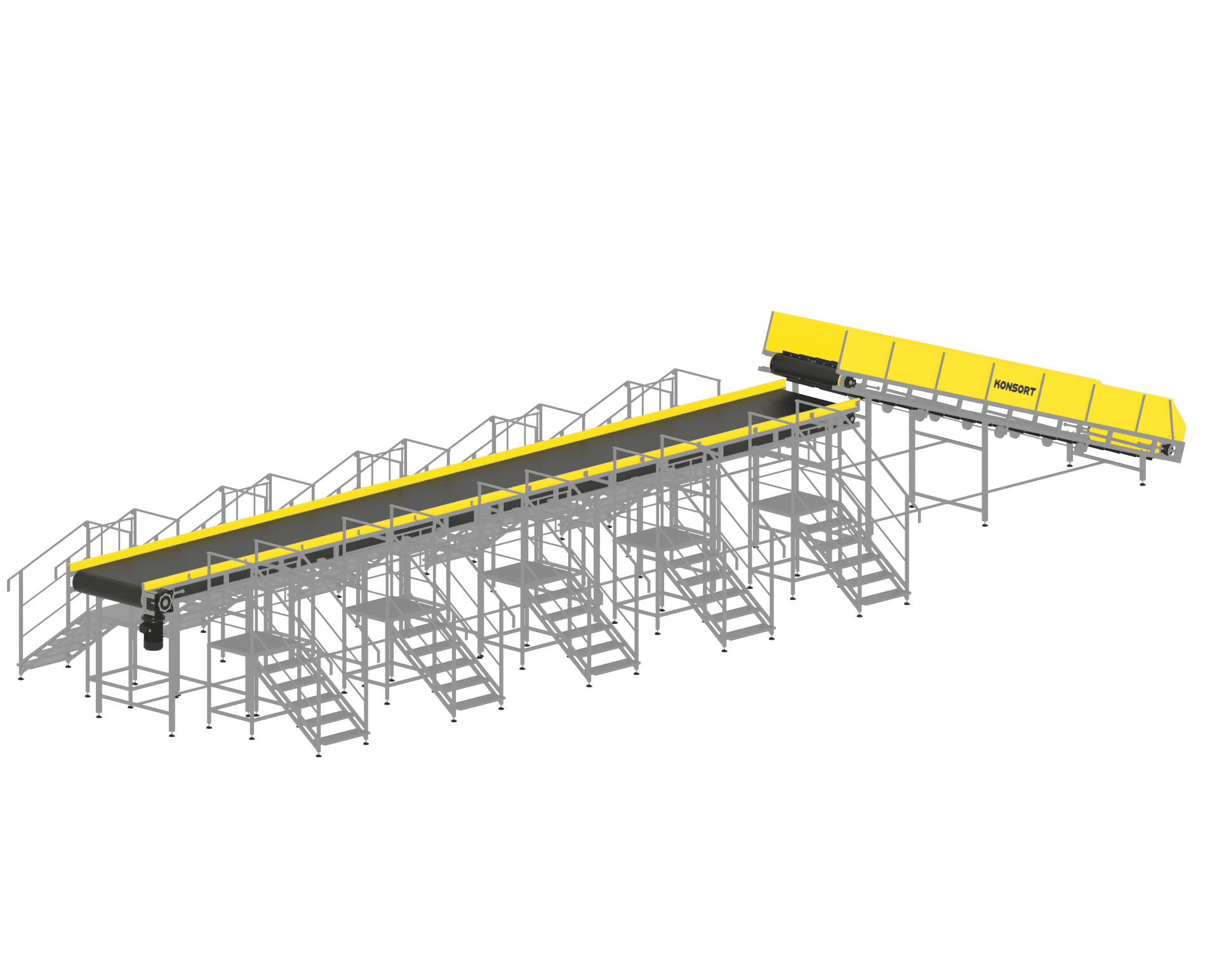

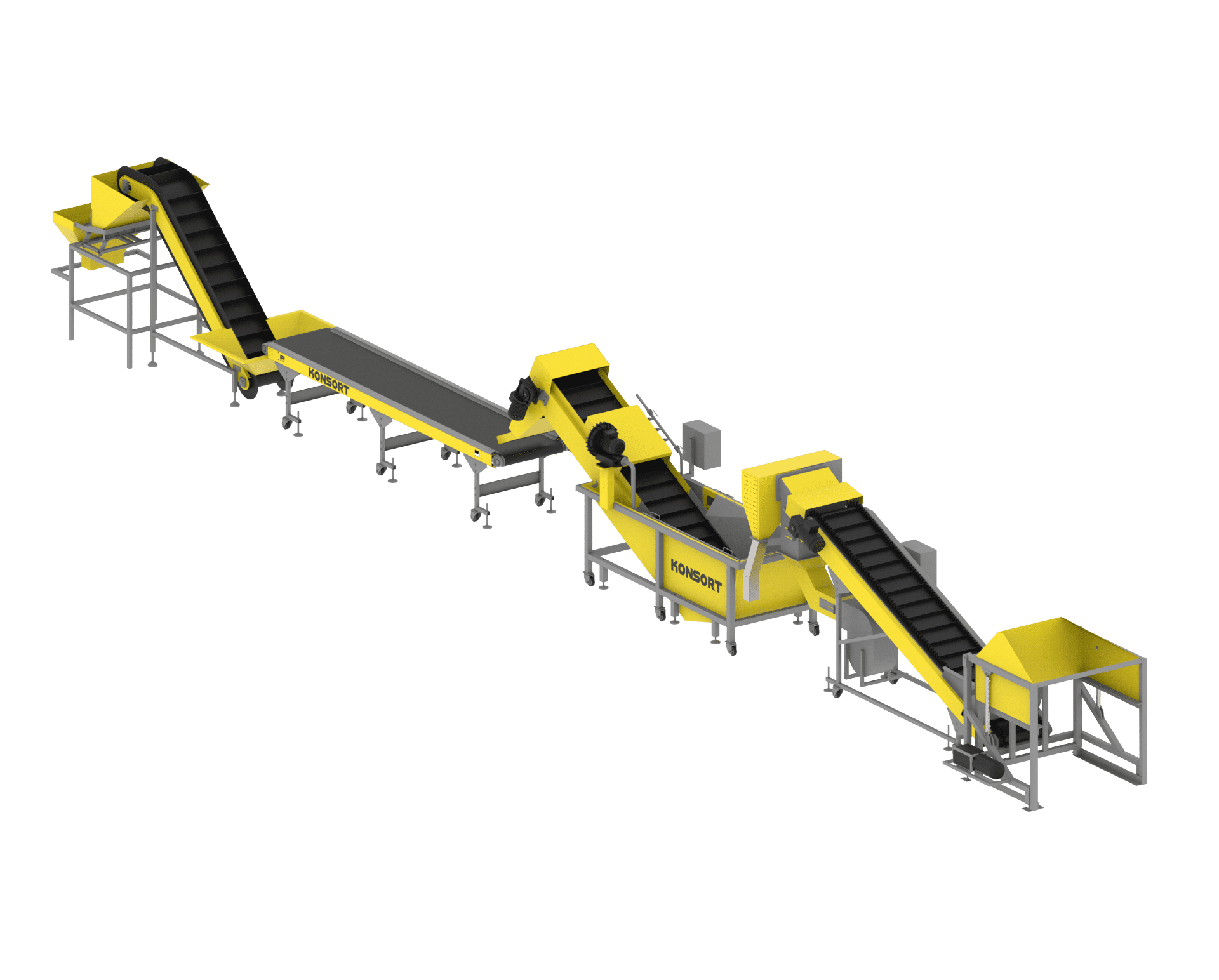

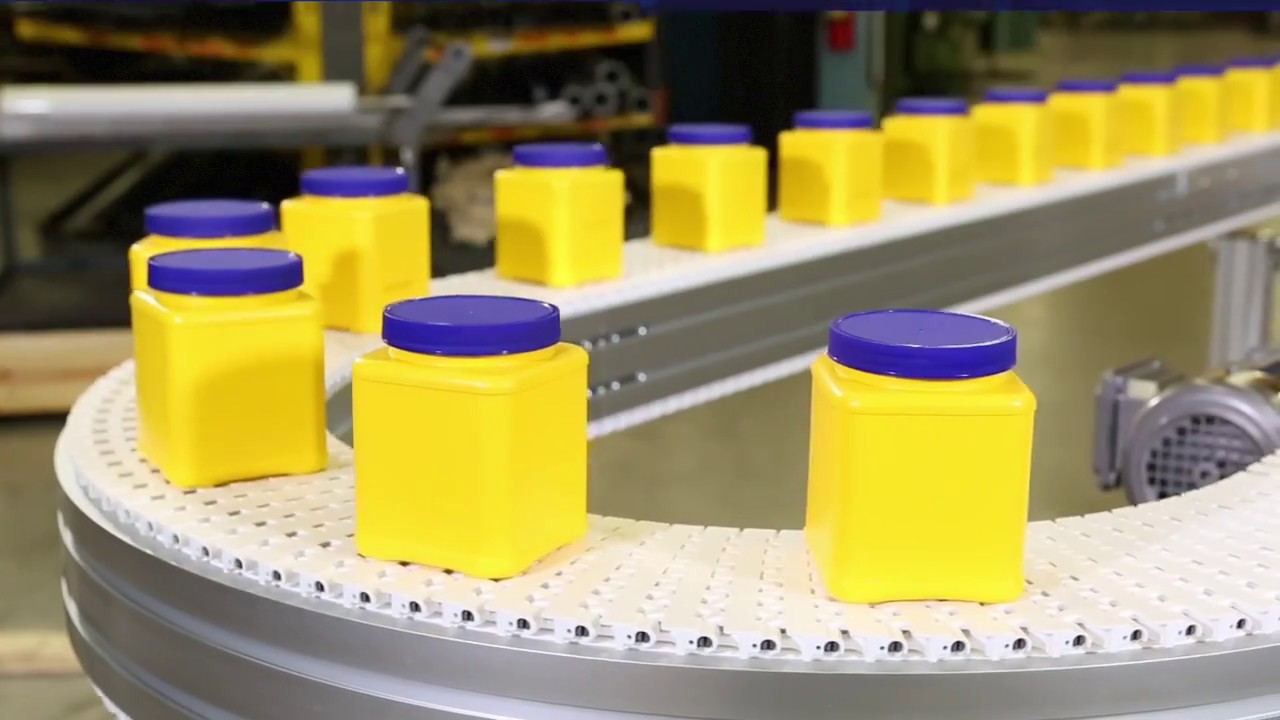

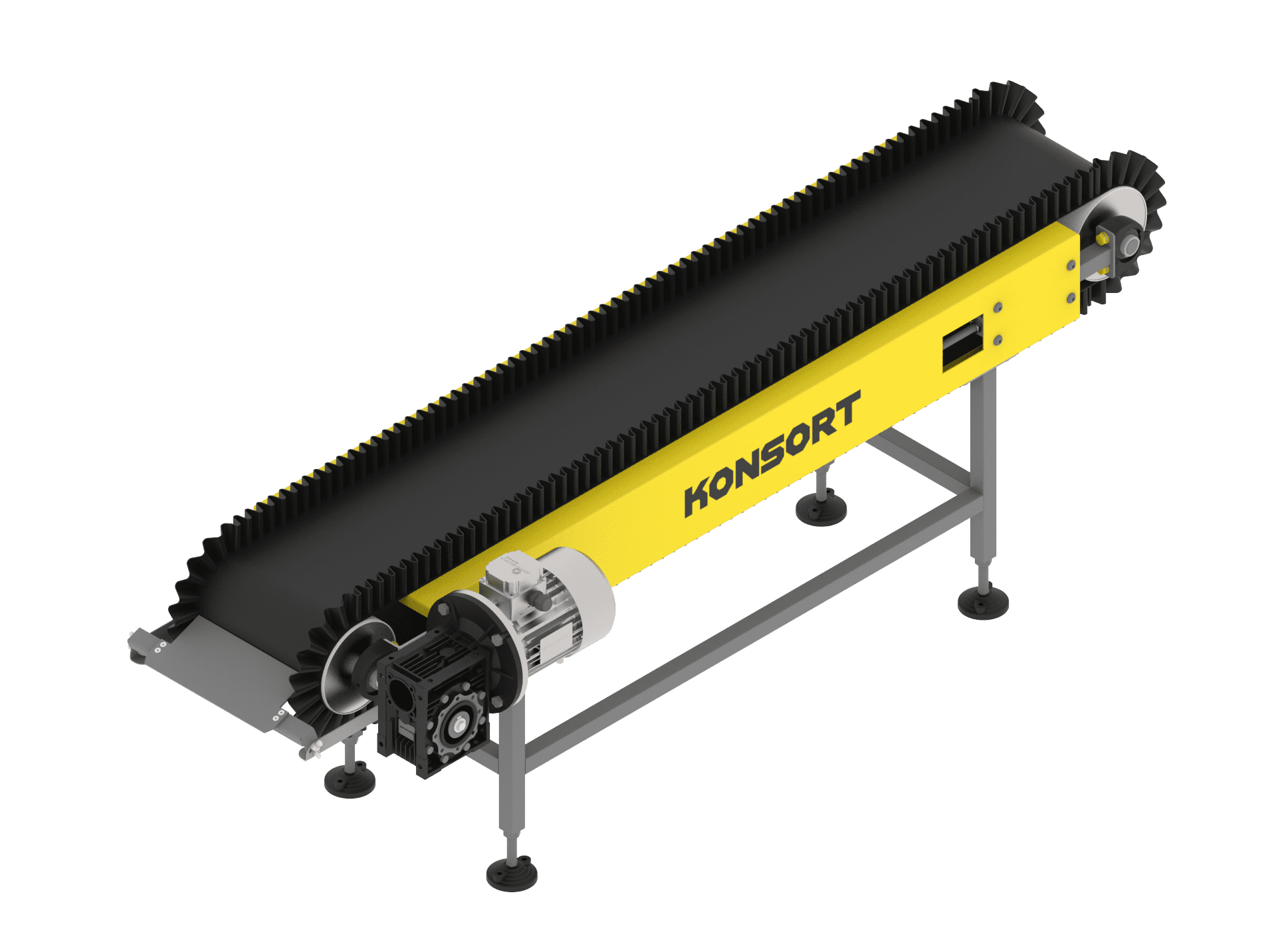

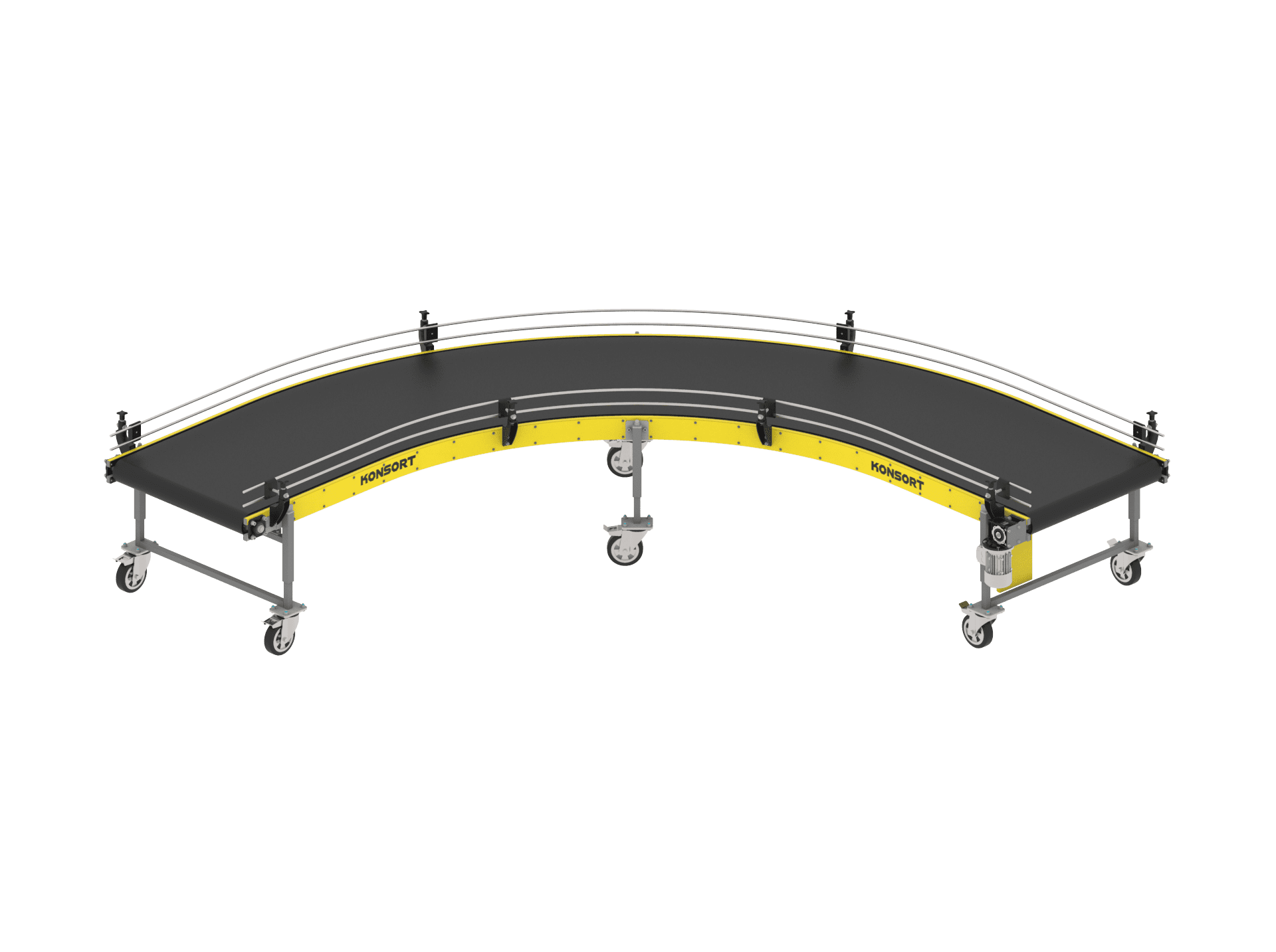

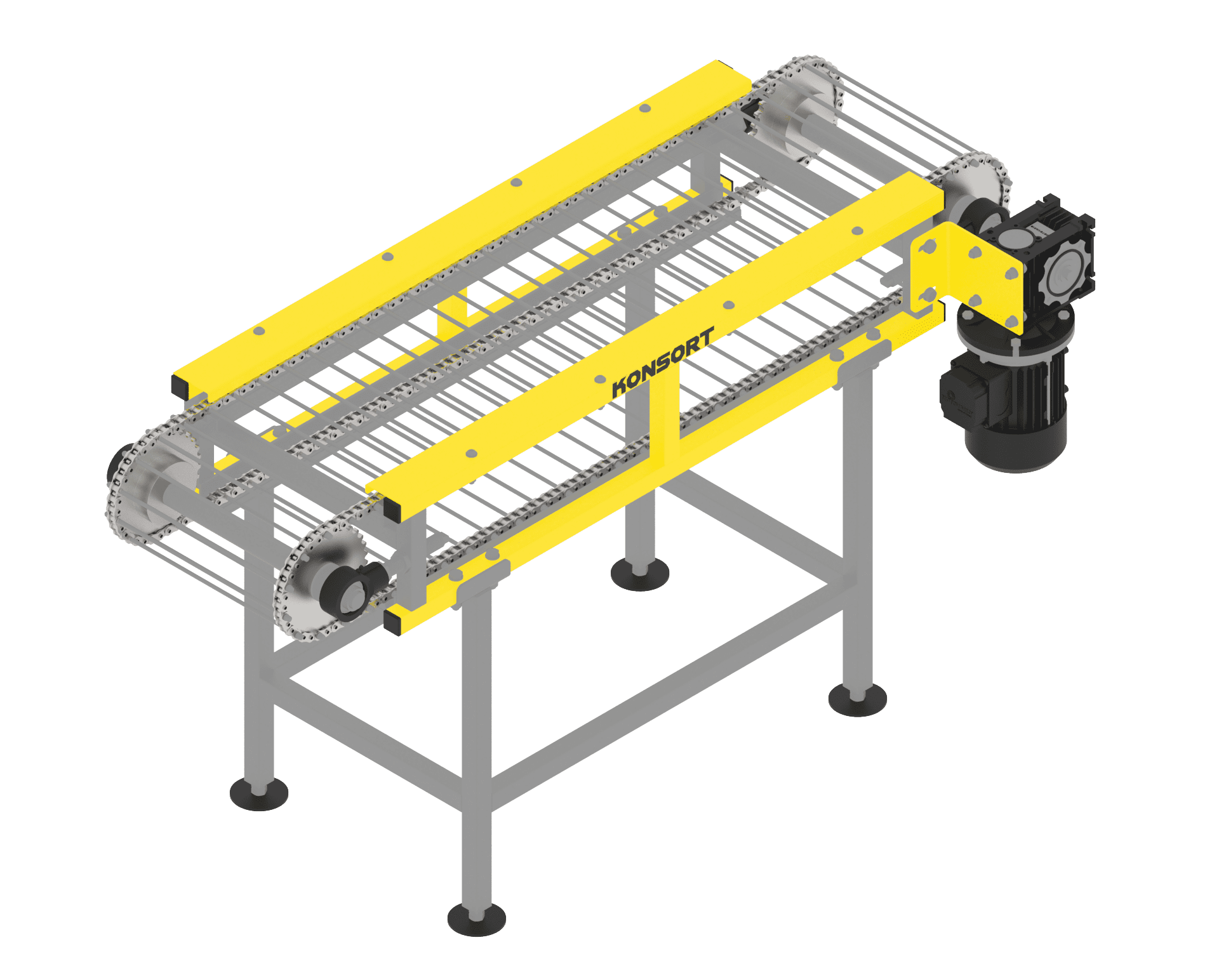

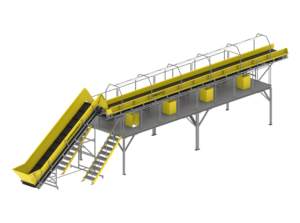

Due to their diversity conveyors can be used in various areas of production. They are used for different sized cargo, bulk raw materials, artificial and other types of products. They are used in any industry.

Production automation;

- Saving time;

- Jobs reduction;

- Lossless transportation for any distance;

- Adjust to any equipment;

- Mounted into an existing production line;

- The complex is used as a system of cargo delivery, supply or redirection;

- Conveyors of various types combination (straight, inclined, horizontal, vertical, rotary, L-shaped, with different types of belts, chain, grooved, scraper, etc.).

- Productivity increases.

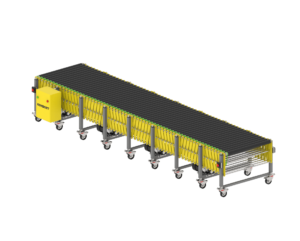

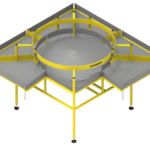

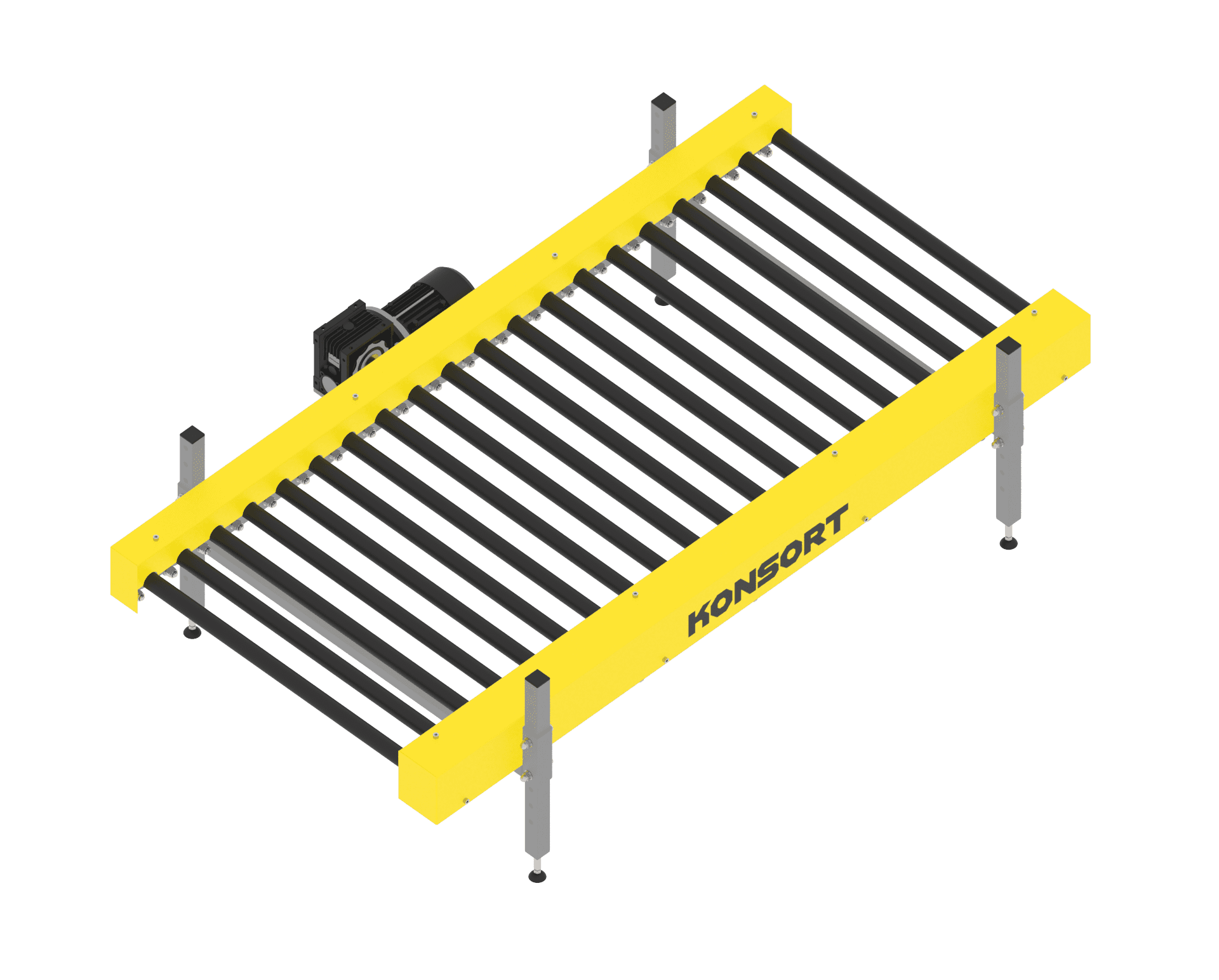

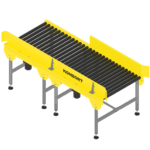

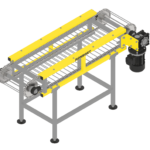

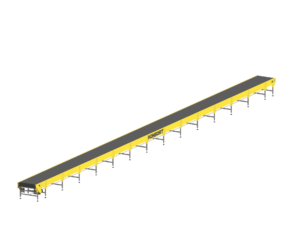

Roller conveyors are designed for transportation of bulky containers, boxes, and pallets. They allow you to move the load horizontally or lift it at a slight angle, providing a constant movement speed.

Transportation process automation;

- Product damage minimization;

- Processed products quality improving;

- Mobility and adaptation to existing equipment in production;

- Design flexibility and compactness (sliding roller conveyor (pantograph);

- Used to go from stage to stage;

- Changing products movement direction while keeping their position;

- Production capacity increase.

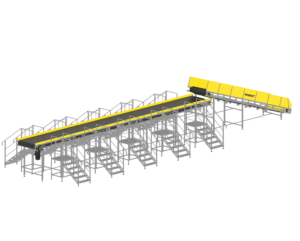

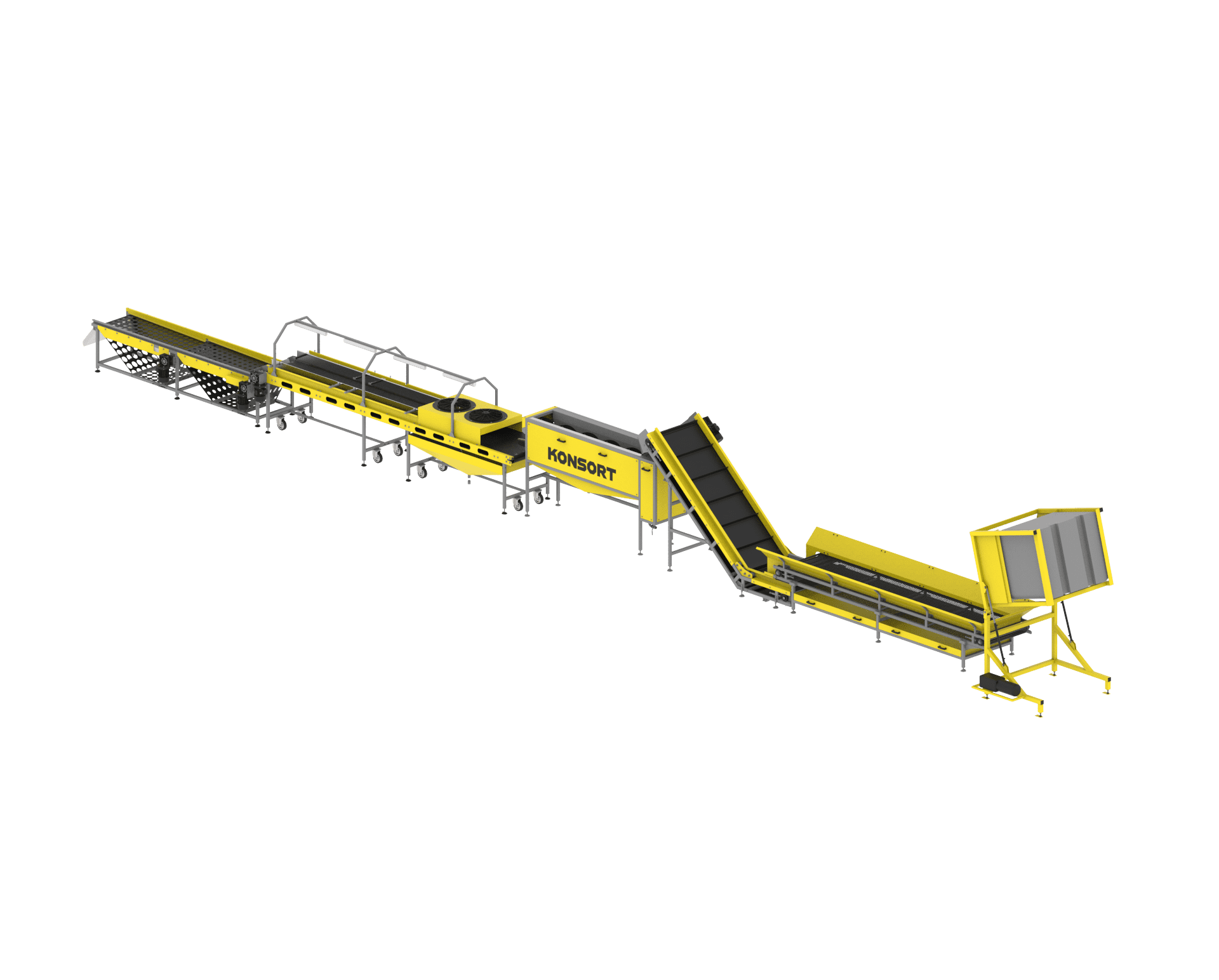

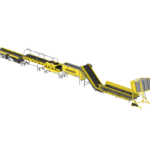

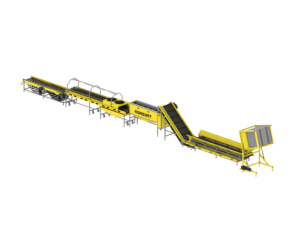

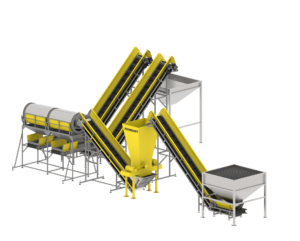

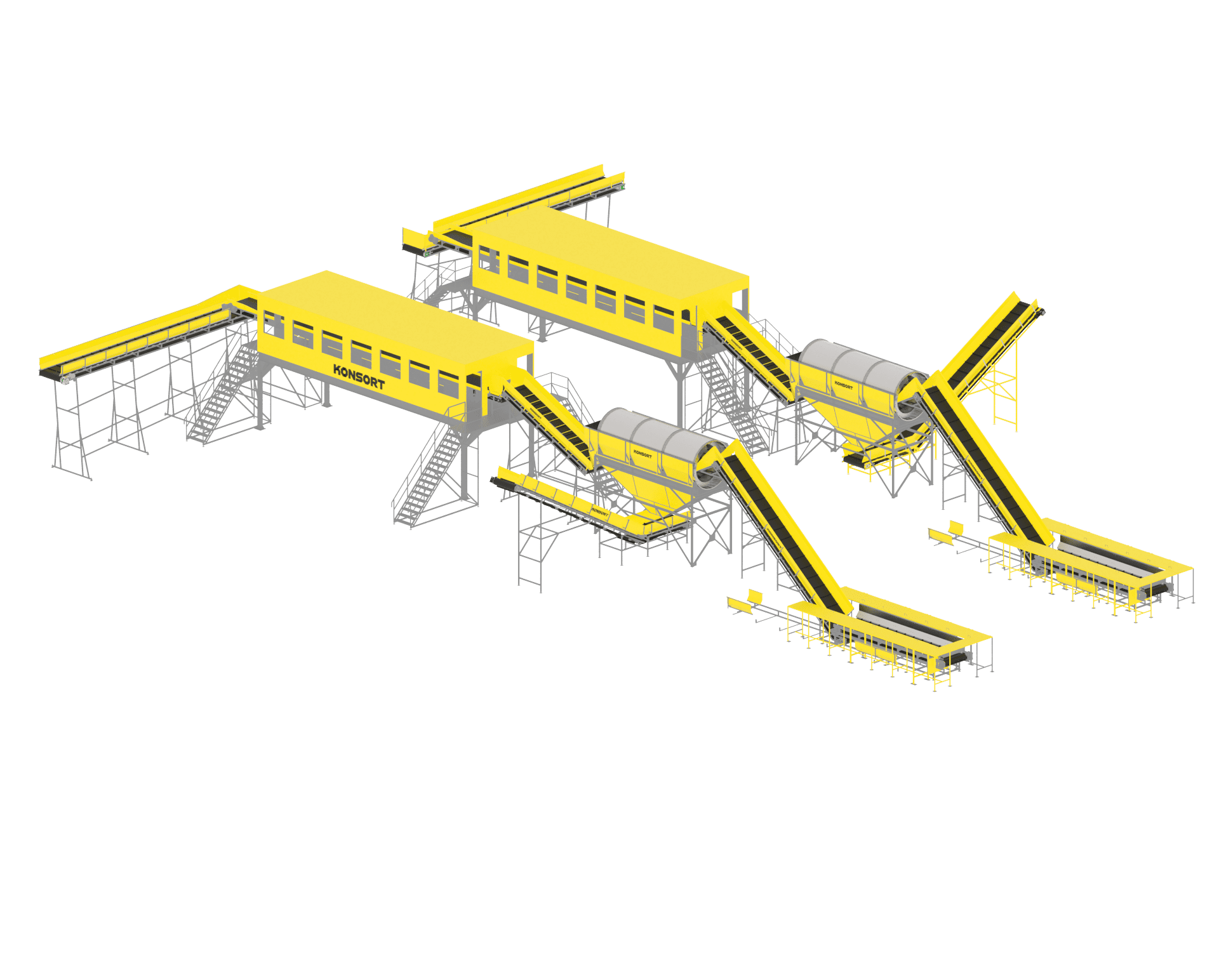

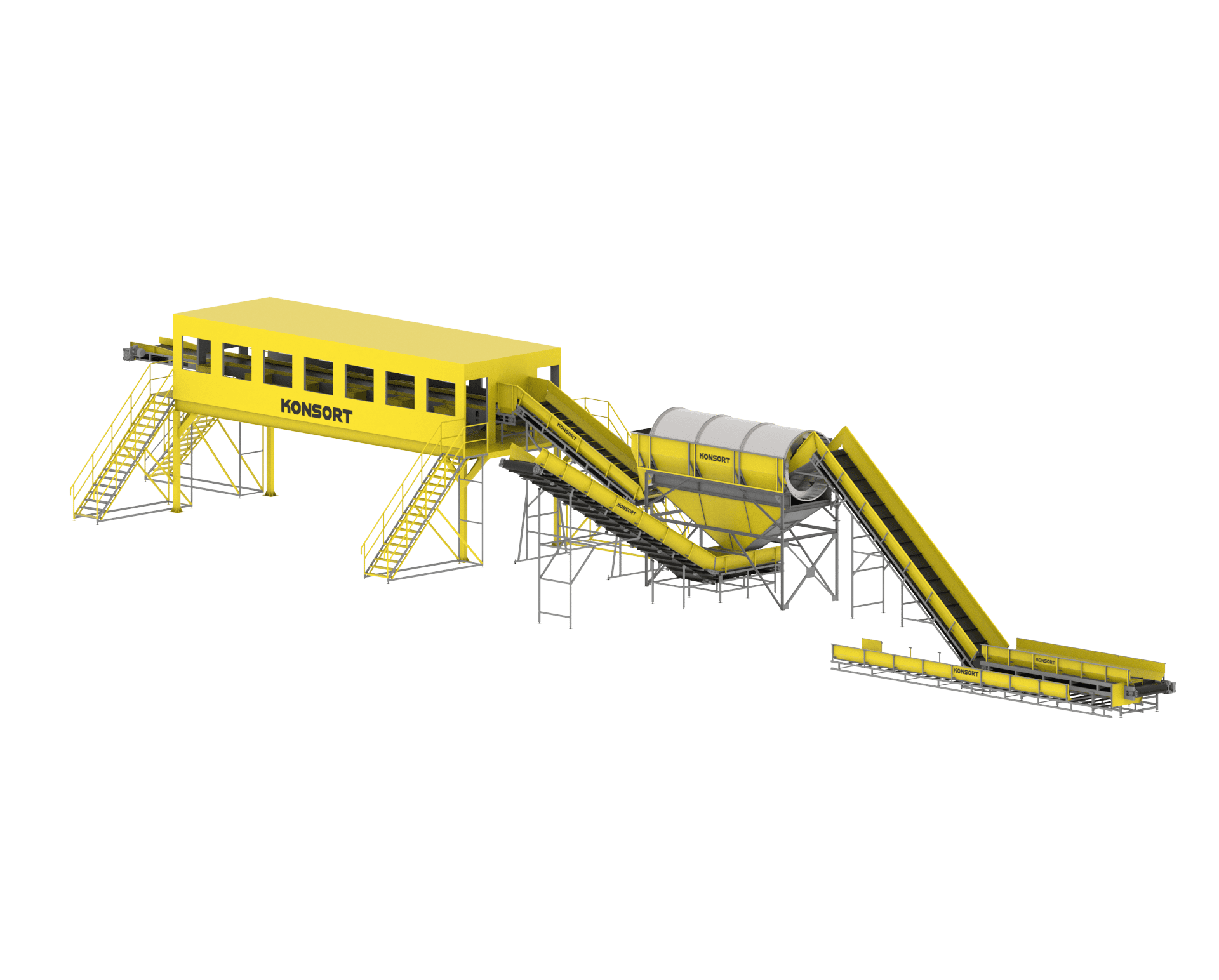

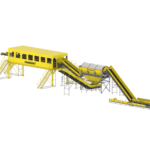

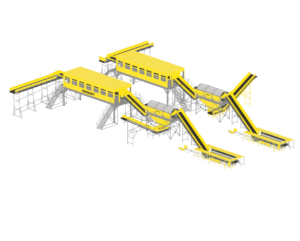

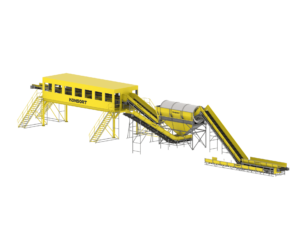

Our sorting lines of various capacities will help you to ease the most difficult stage of processing. Their purpose is to sort solid domestic waste for further pressing of valuable secondary raw materials and its sale to processing companies.

Individual projects for each customer in accordance with the sites allocated for processing;

- Environmental cleaning from pollution;

- Additional jobs;

- Waste processing activity mechanization;

- Increased sorting performance;

- Additional income for the community from the sale of sorted and compressed raw materials;

- Fast payback period provided 100% of operation.

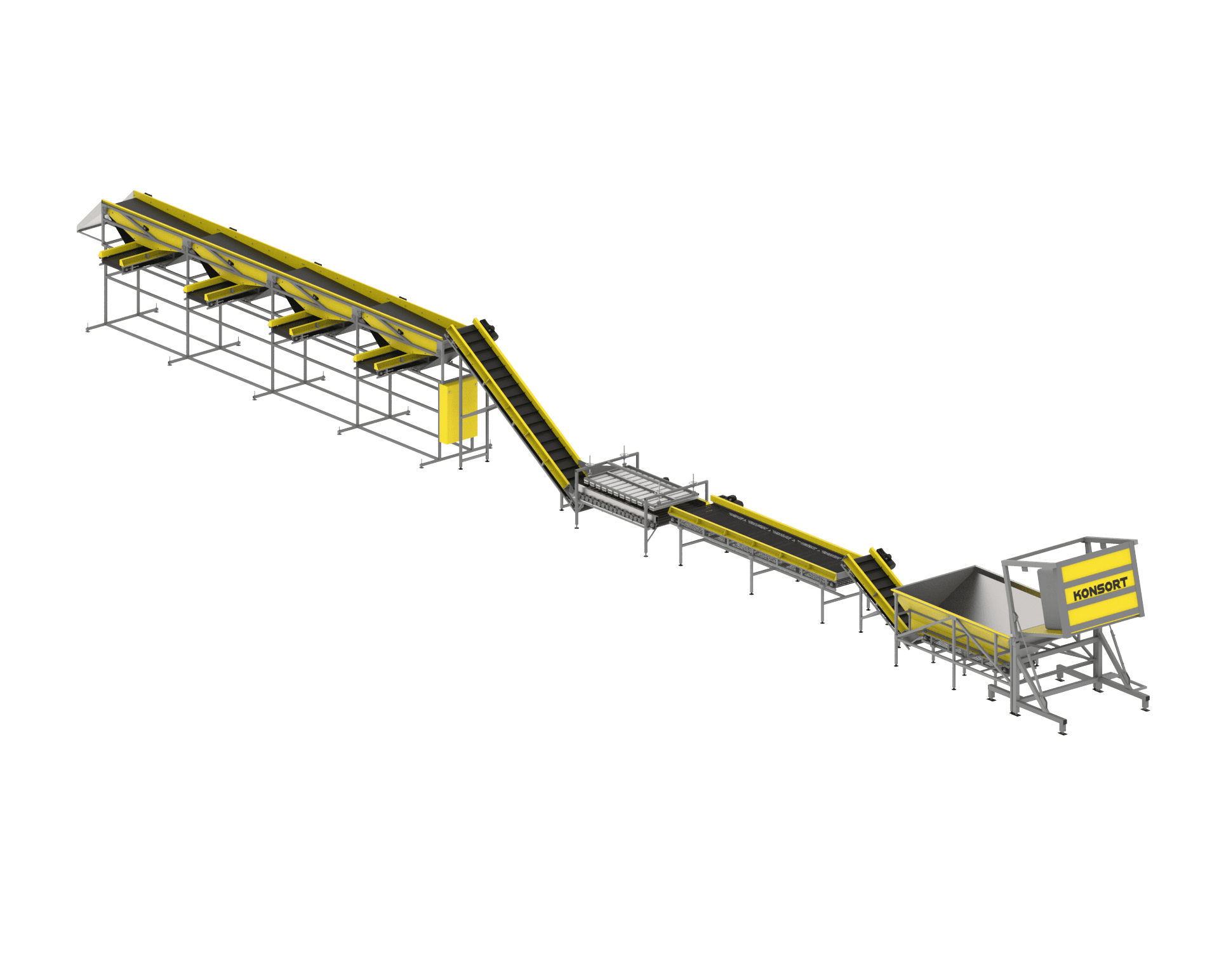

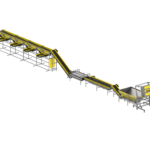

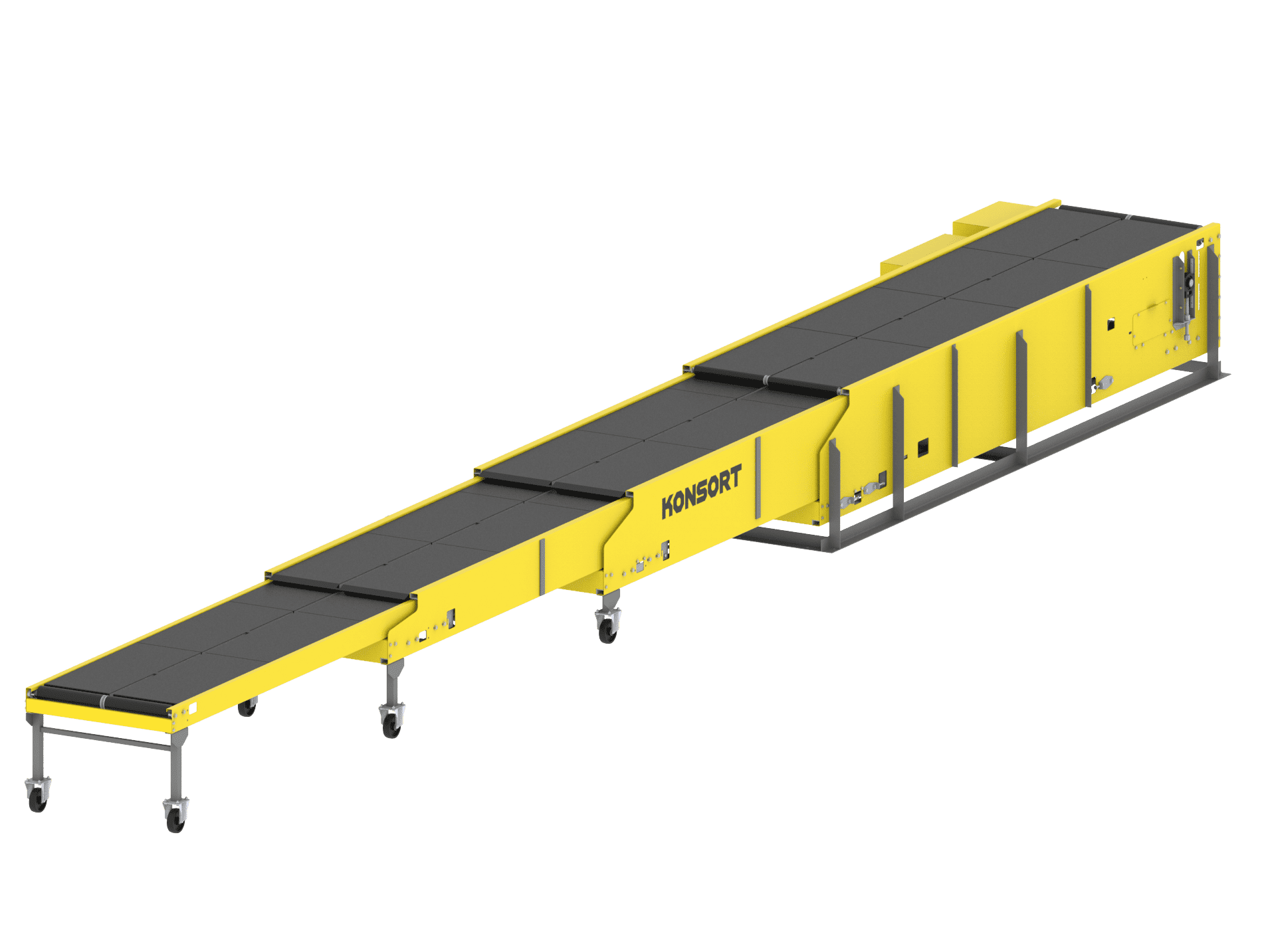

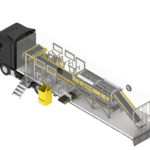

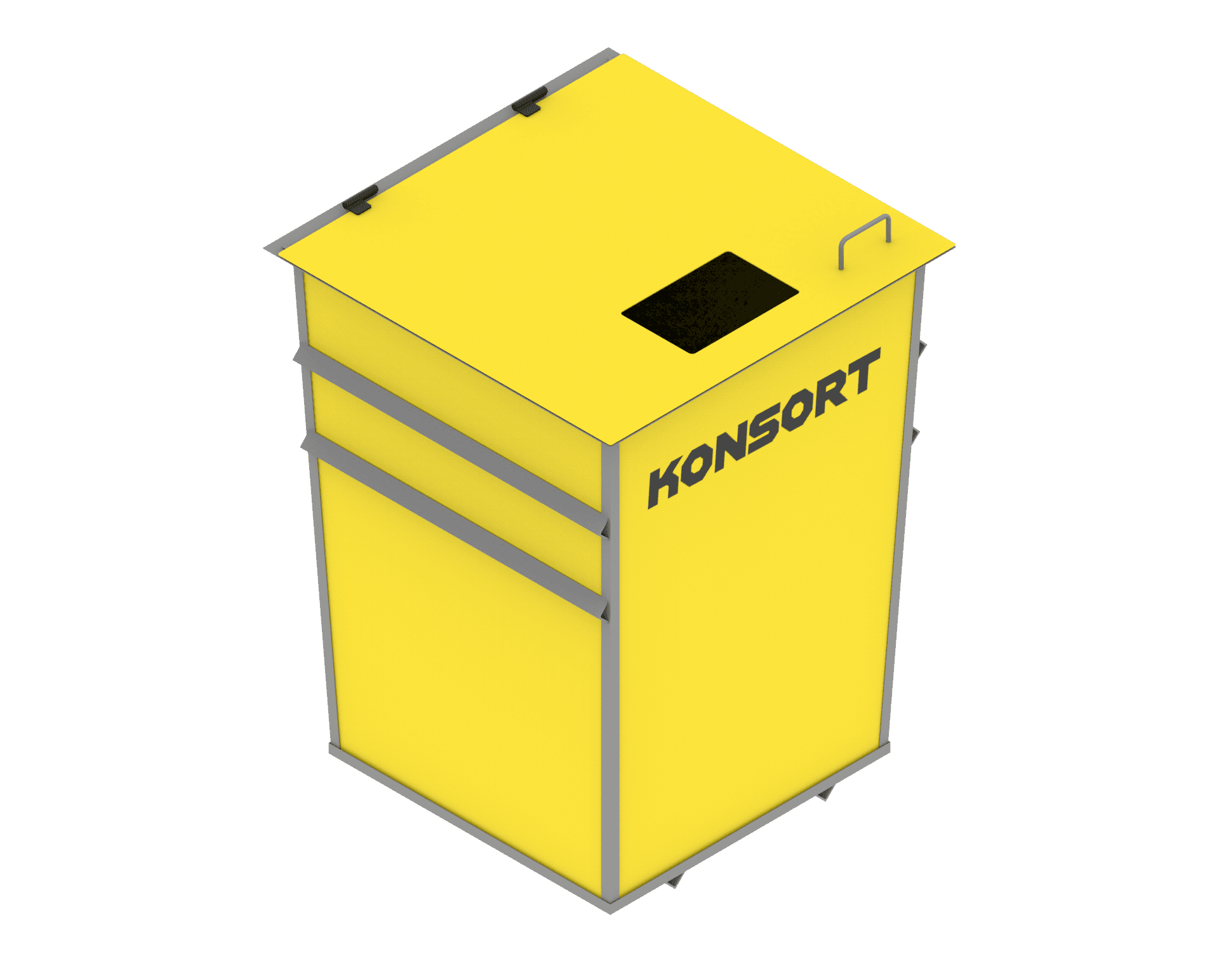

Mobile line for sorting solid domestic waste will help to sort SDW without reference to a place. With this mobile line it is possible to recycle waste at small landfills, enterprises, hotels or industrial facilities.

Non-location-dependent;

- Area contamination problem solving;

- Additional jobs;

- Recycling “spontaneous” dumps;

- Sorted raw materials sales profit;

- Additional income from line rental;

- Energy savings (solar panels on the roof of the mobile sorting line);

- Improving area ecology.