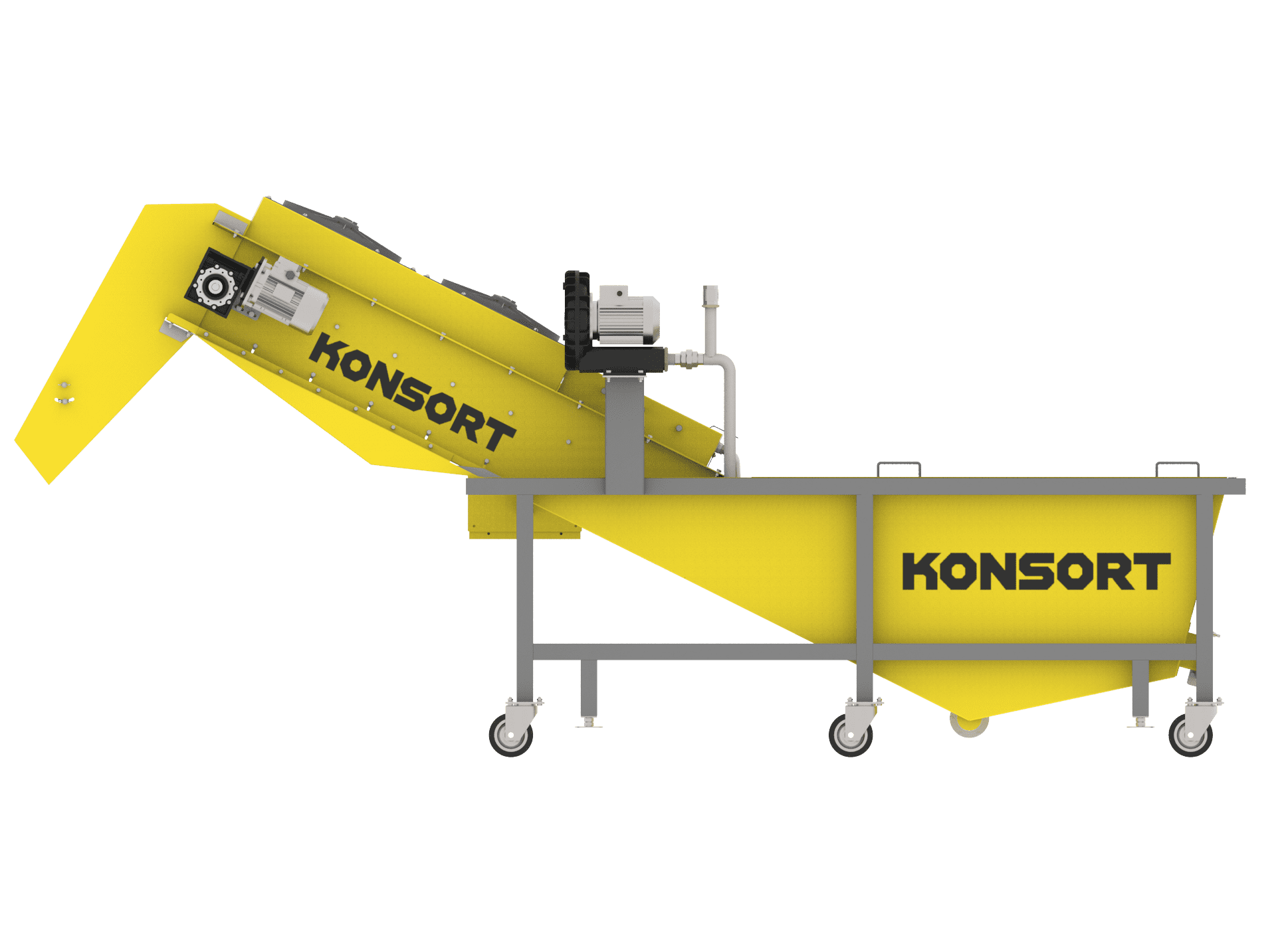

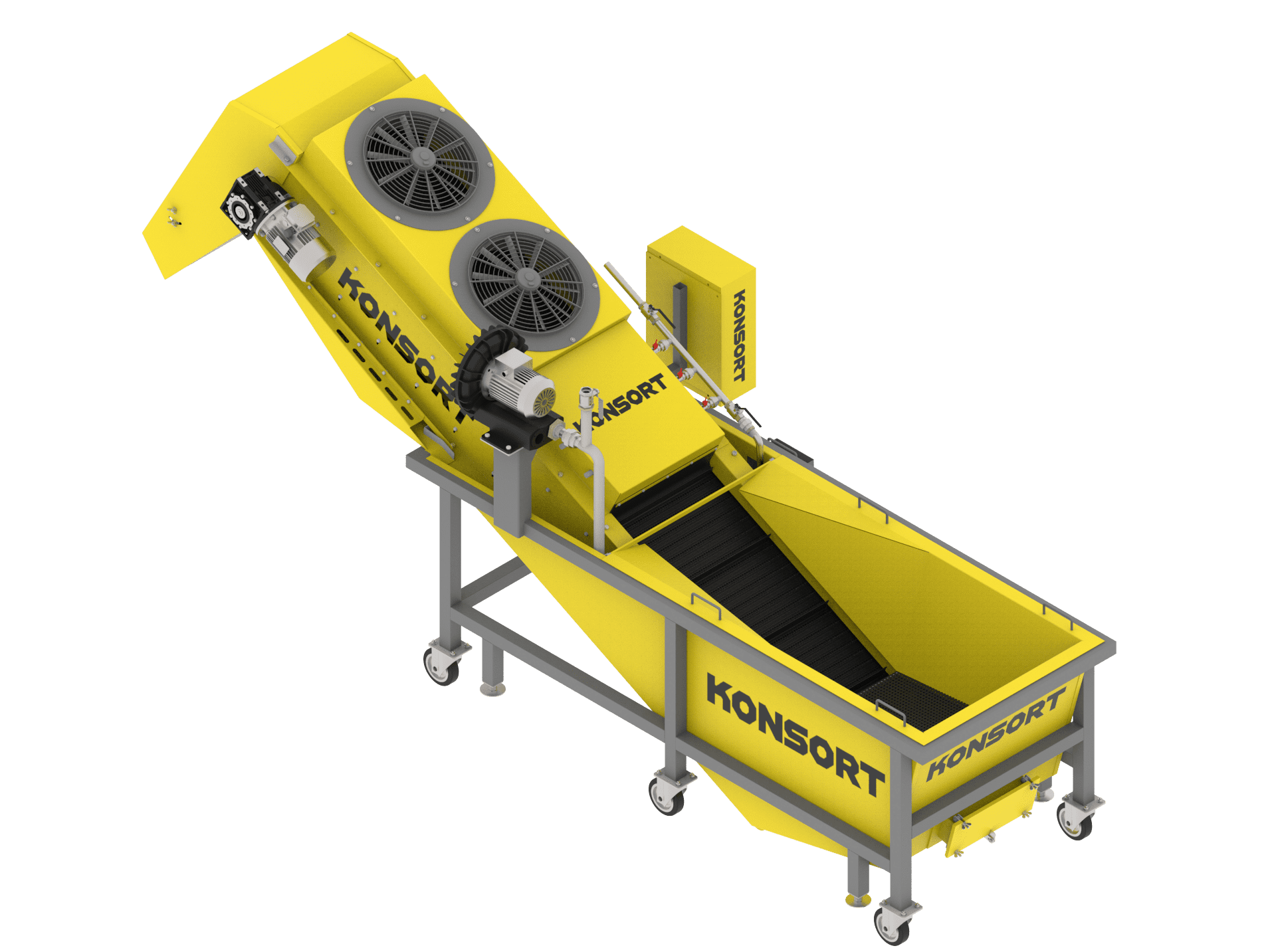

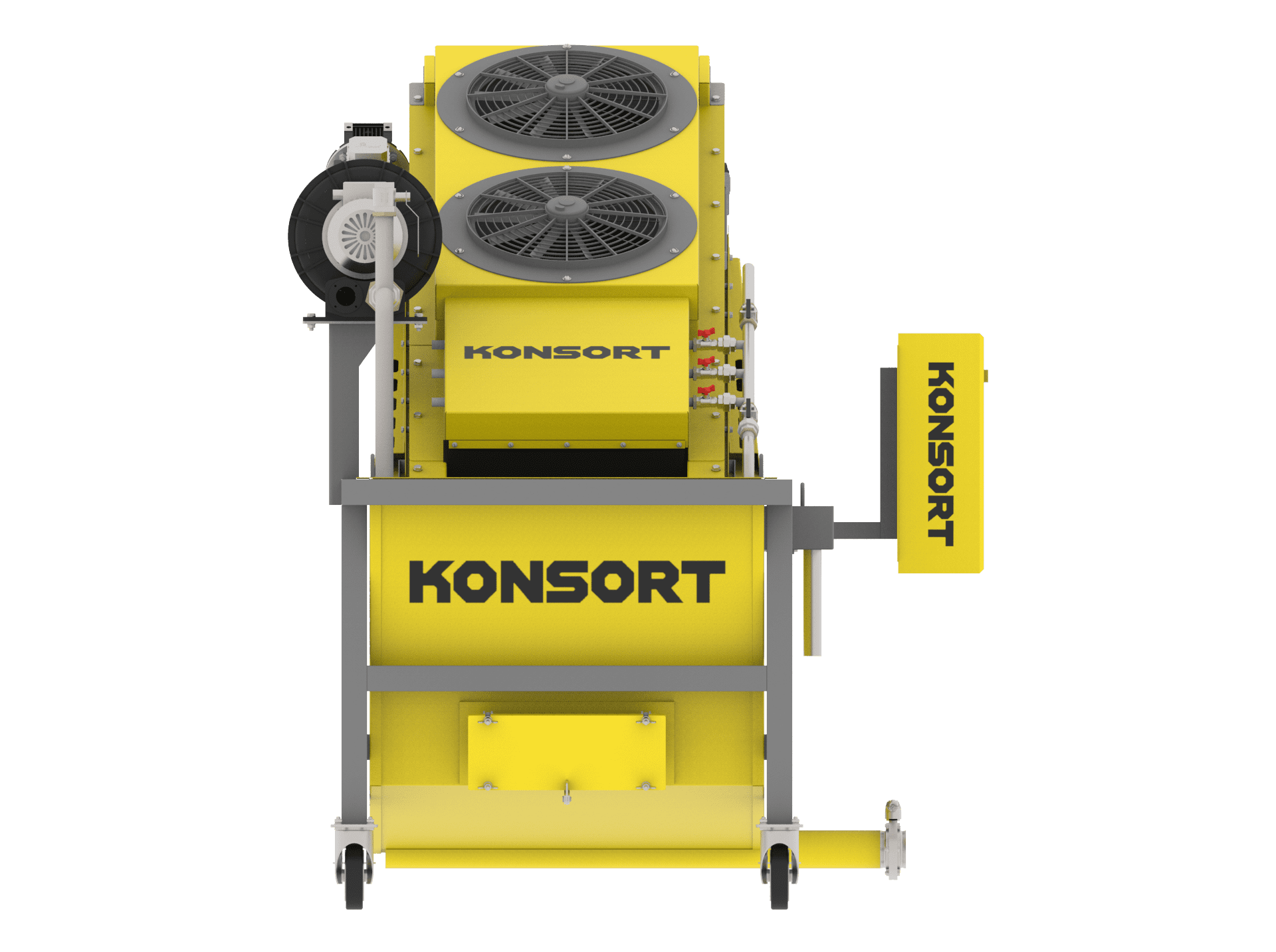

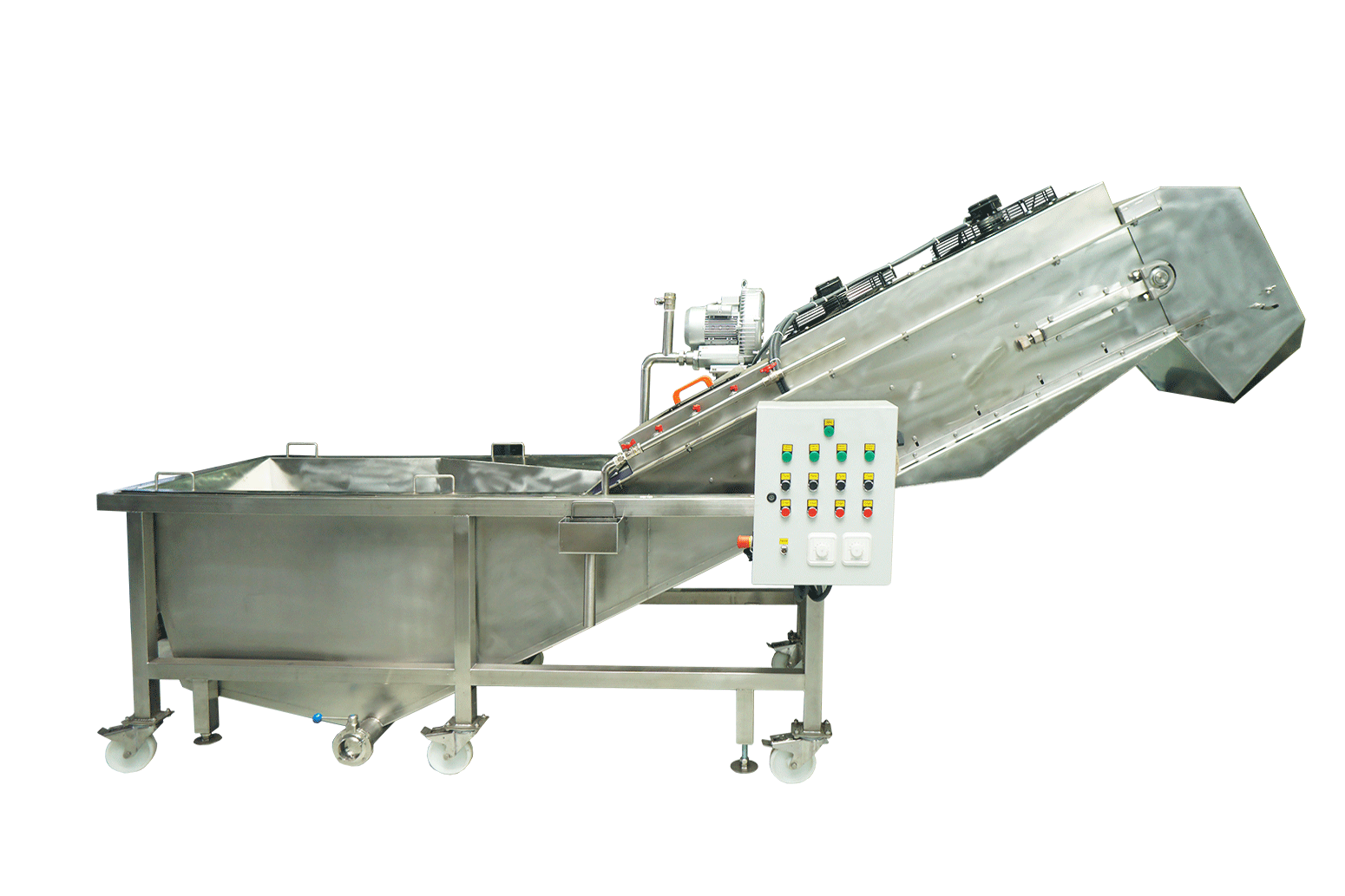

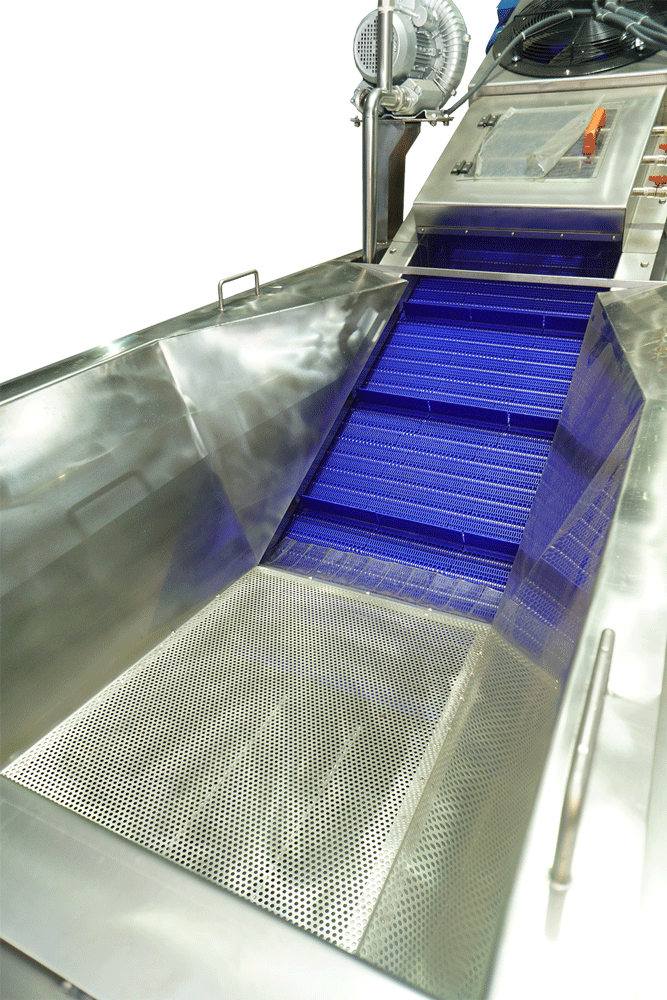

Bubble washer (for non-sinking products)

The air bubble washer for floating products is a professional solution designed for food industry enterprises that require thorough and gentle washing of products that do not sink in water. These include apples, pears, peppers, leafy greens, cucumbers, tomatoes, as well as lightweight or pre-packaged fruits and vegetables.

Principle of operation

The product is loaded into a water-filled tank. Compressed air is supplied through openings at the bottom of the tank, generating a powerful stream of microbubbles. This creates a turbulent water-air environment that gently stirs the products.

As a result:

-

gentle surface cleaning occurs without damaging the product structure;

-

dirt, dust, sand, and chemical residues are effectively removed;

-

products remain intact without the need for mechanical intervention;

-

extended contact with water is ensured, which is essential for floating items.

Additionally, the system may include a stainless steel spray section for additional rinsing and an air-blow unit for drying.

Equipment advantages

✅ Ideal for floating produce

✅ Safe cleaning without skin damage

✅ Fully automated washing process

✅ Built from AISI 304 food-grade stainless steel

✅ Easy to maintain and clean

✅ Custom design tailored to specific requirements

Buy air bubble washer for floating products in Ukraine or internationally

KONSORT, a Ukrainian equipment manufacturer with over 15 years of experience, offers affordable air bubble washers directly from the factory. This means:

-

Competitive pricing with no hidden markups;

-

Professional consultation and configuration selection;

-

In-house production — from engineering to commissioning;

-

Delivery within 15–20 working days;

-

18-month warranty and post-sale support.

Improving the washed product quality, reducing damage of raw materials

Improving the washed product quality, reducing damage of raw materials  Productivity increase up to 70%

Productivity increase up to 70%  Workforce optimization up to 30%

Workforce optimization up to 30%  Reduction in human-related risks

Reduction in human-related risks - At agricultural product processing plants

- In freezing and packaging facilities

- At logistics hubs and distribution centers prior to packing and sale

- On processing lines before grading or drying of the products

- European design

- Manufacturing process automation, high-quality result

- Thorough and gentle cleaning

- Preservation of product qualities

- Payback in 9 months