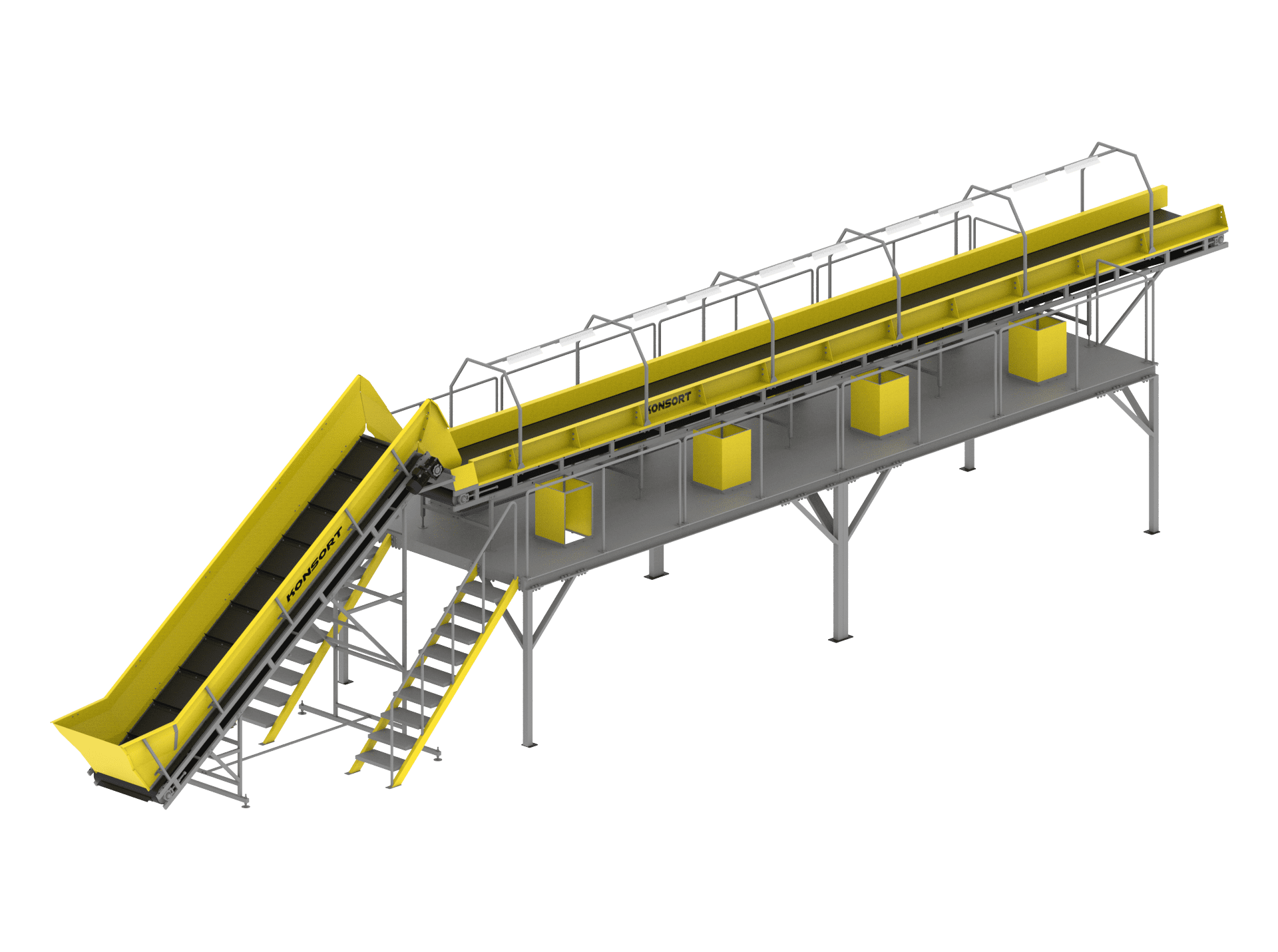

Line for sorting solid waste 10 000 tons per year

The solid waste sorting complex provides selection of valuable secondary raw materials out of waste and then sending them to the final processing points. Solid waste goes to the receiving department to the specially designed pits, where the receiving L-type conveyor is located. Then raw materials with the help of inclined conveyor go to the inspection (sorting) conveyor for manual sorting of useful secondary raw materials. Special containers for collecting solid waste are installed under the inspection table.

Technical characteristics:

Line dimensions

18 000 * 4 000 * 5 000 mm

Electric power consumption

7 kW per hour

Continuous line operation

8 hours

Stop for technical inspection

2 hours

Number of working shifts

2

Number of staff for one shift (8 hours):

Sorting operator

up to 8 people

Line operator

1 person

Loader driver

1 person

Line components:

Inclined conveyor

1 unit

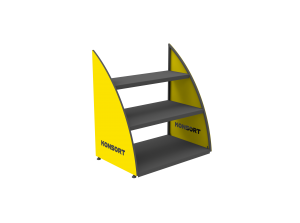

Mezzanine

1 unit

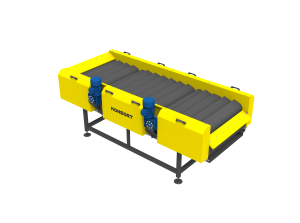

Inspection conveyor (sorting)

1 unit

Containers for collecting sorted waste

The equipment can be designed according to individual parameters necessary for the customer

Economic advantage:

Improving products quality and grade by 80%

Improving products quality and grade by 80%  Productivity increase up to 80%

Productivity increase up to 80%  Lower production costs by 40%

Lower production costs by 40%  Reduction in human-related risks by 20%

Reduction in human-related risks by 20%

Spheres of usage:

- The line is used at landfills or separately built plants for crushing and sorting various waste: domestic waste, mixed waste, construction waste, organic and inorganic waste, waste paper and polymers, with the purpose of their further reuse and disposal

Benefits and options:

- European design provides a professional and clean look

- Durable powder coating

- There is possibility to complete the line with extra components if necessary

- Installation of video surveillance

- Sound and light alarm

(UA) Про нас говорять

With these products are often ordered