Methods for processing agricultural products

- Berry processing for further freezing.

- Fruit processing into juices, purees, and other end products.

- Vegetable preparation for packaging and retail.

- Grain and legume cleaning for further processing.

- Nut processing for sorting and calibration.

- Garlic processing, including peeling, packaging, and storage.

- Raw material transportation from washing to drying, with options for weight and quality control.

- Comprehensive vegetable mix processing for flash freezing.

- Raw material cleaning for herbal teas and aromatic blends.

- Thermal fruit treatment for drying.

KONSORT Equipment for Raw Material Processing

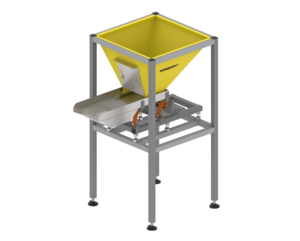

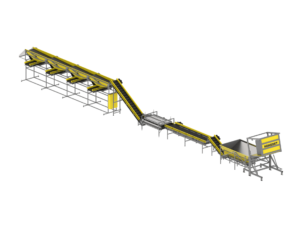

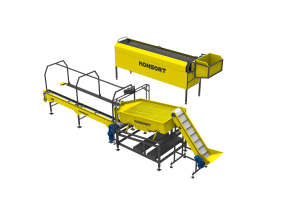

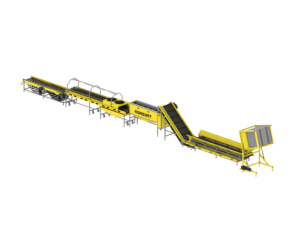

1. Belt Conveyors

Used for transporting raw materials between processing stages. Available with perforated belts for draining liquids or small debris.

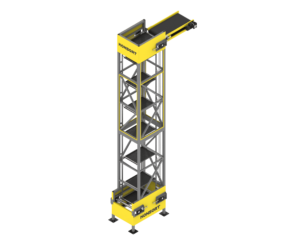

2. Roller Conveyors

Designed for moving boxes, containers, and other packaging. Equipped with lifts for multi-level distribution.

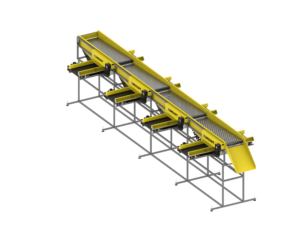

3. Calibration Conveyors

Sort products by size or weight.

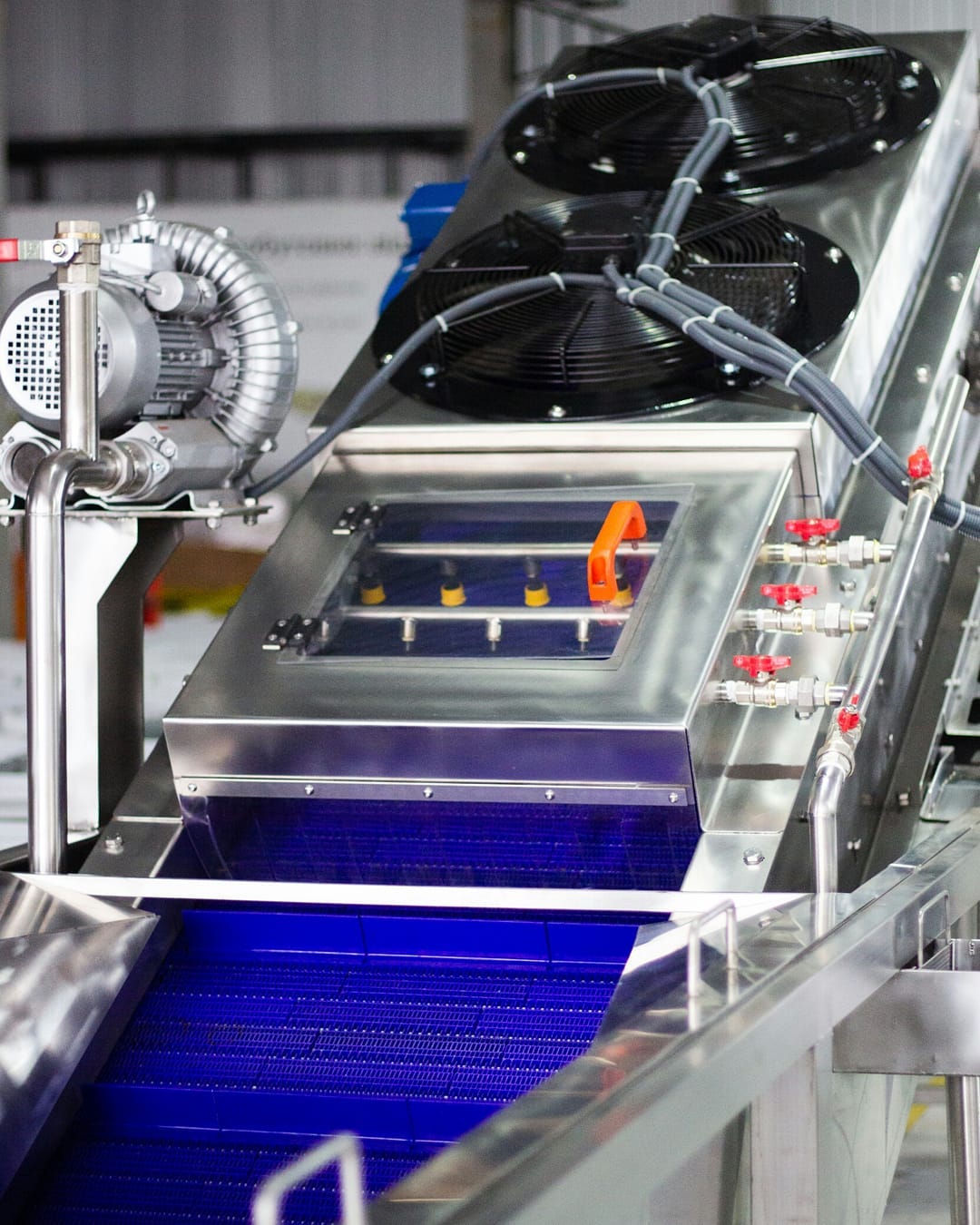

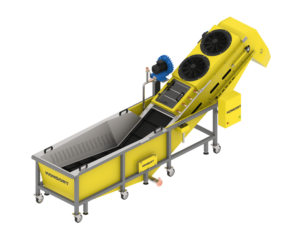

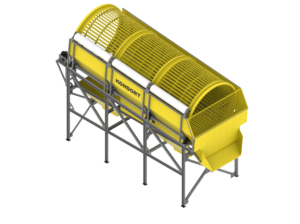

4. Bubble Washers

Provide thorough cleaning of fruits, vegetables, and berries by agitating water to remove dirt and impurities.

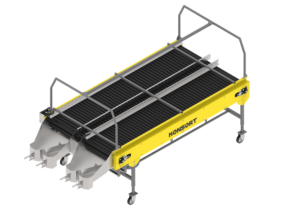

5. Sorting Tables

Allow manual inspection and additional sorting of products before packaging.

6. Universal Vegetable Lines

Comprehensive solutions for vegetable processing, including washing, cutting, weighing, and packaging.

7. Nut Processing Line

Equipped with machines for cleaning, size grading, and calibration.

8. Garlic Processing Line

Includes equipment for mechanical peeling, clove separation, calibration, and packaging.

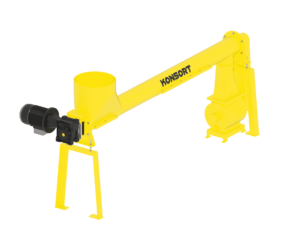

9. Drying Units

Used for thermal treatment of fruits, berries, and vegetables before packaging or further processing.

10. Systems for Transporting to Freezing Units

Ensure fast and safe delivery of products to shock-freezing chambers.

11. Optical Sorters

Automatically identify and remove defective products based on color or shape.

12. Automatic Packaging Lines

Used for final packaging in individual or bulk containers.

Advantages of Automation in Raw Material Processing

- Increased productivity.

Process up to 40% more raw materials in the same time frame. - Reduced losses.

Accurate sorting and processing decrease waste by 20–30%. - Resource efficiency.

Optimal use of water, electricity, and labor. - Product quality.

Ensures consistency and maintains freshness and quality. - Quick return on investment.

Equipment typically pays off within 2–3 years due to reduced operational costs.

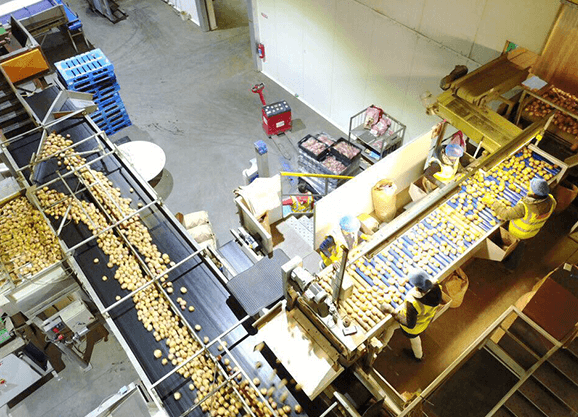

Case Study: Implementation Success

Company: LLC “SmakOvoch”

Industry: Production of frozen vegetable mixes.

Solution: Installation of a comprehensive vegetable processing line.

Description:

The company approached KONSORT to automate the washing, cleaning, calibrating, and packaging of vegetables. Equipment installed included belt conveyors, bubble washers, calibration systems, and an automated packaging line.

Results:

- Productivity increased by 50%.

- Product losses reduced by 25%.

- Labor costs reduced by 30%.

- Profitability improved by 15%.

Why Choose KONSORT?

KONSORT’s solutions enable businesses of all sizes — from small farms to large agricultural enterprises — to enhance raw material processing, meet market standards, and boost competitiveness. The use of modern systems ensures the continuous movement of products along the processing chain and significantly reduces losses.

Looking to improve productivity?

Purchasing sorting conveyors or ordering transportation systems in Ukraine is a step toward stable growth and increased efficiency for your business.

KONSORT offers comprehensive solutions, including belt conveyors, calibration systems, and transportation lines, ensuring fast and precise sorting.