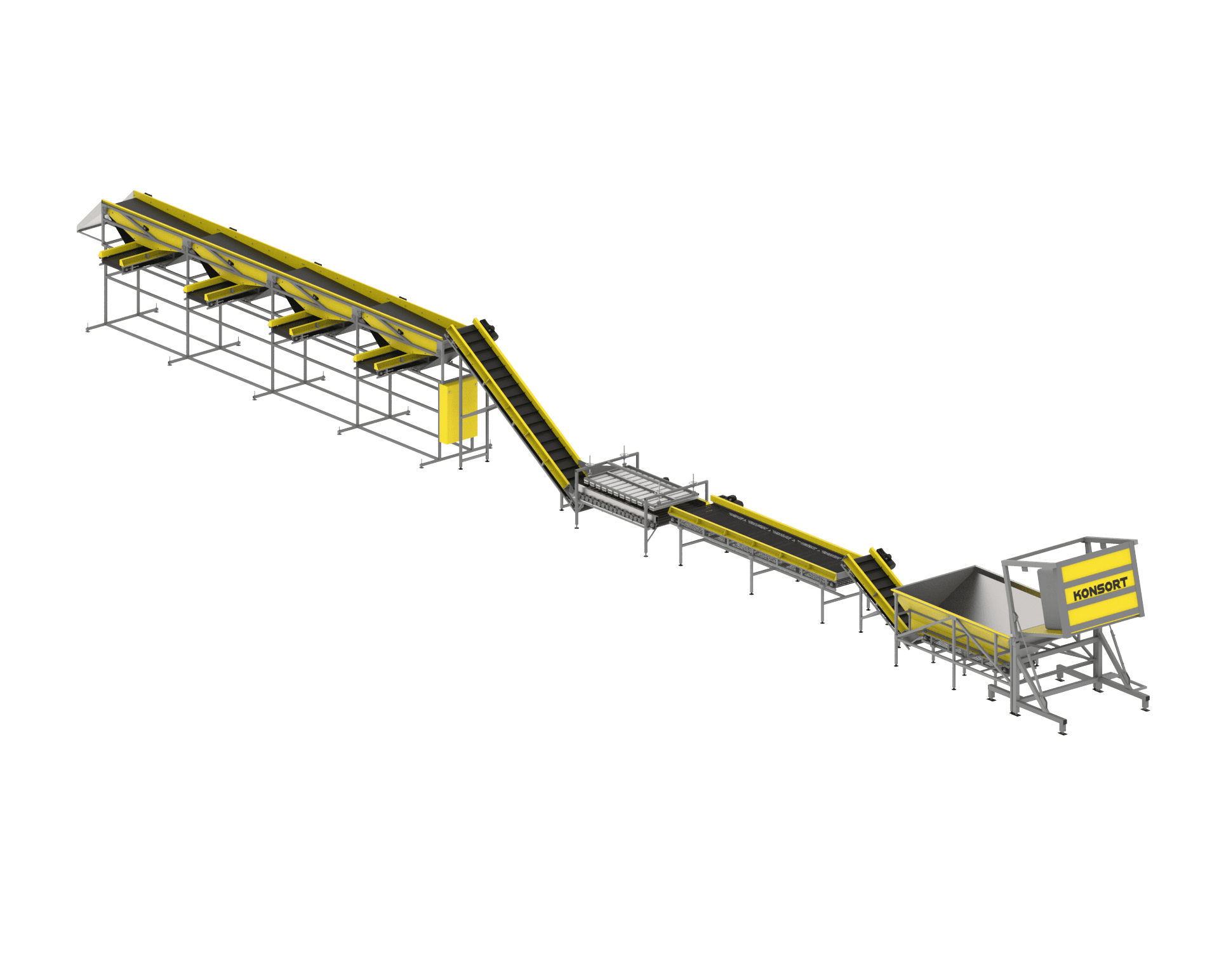

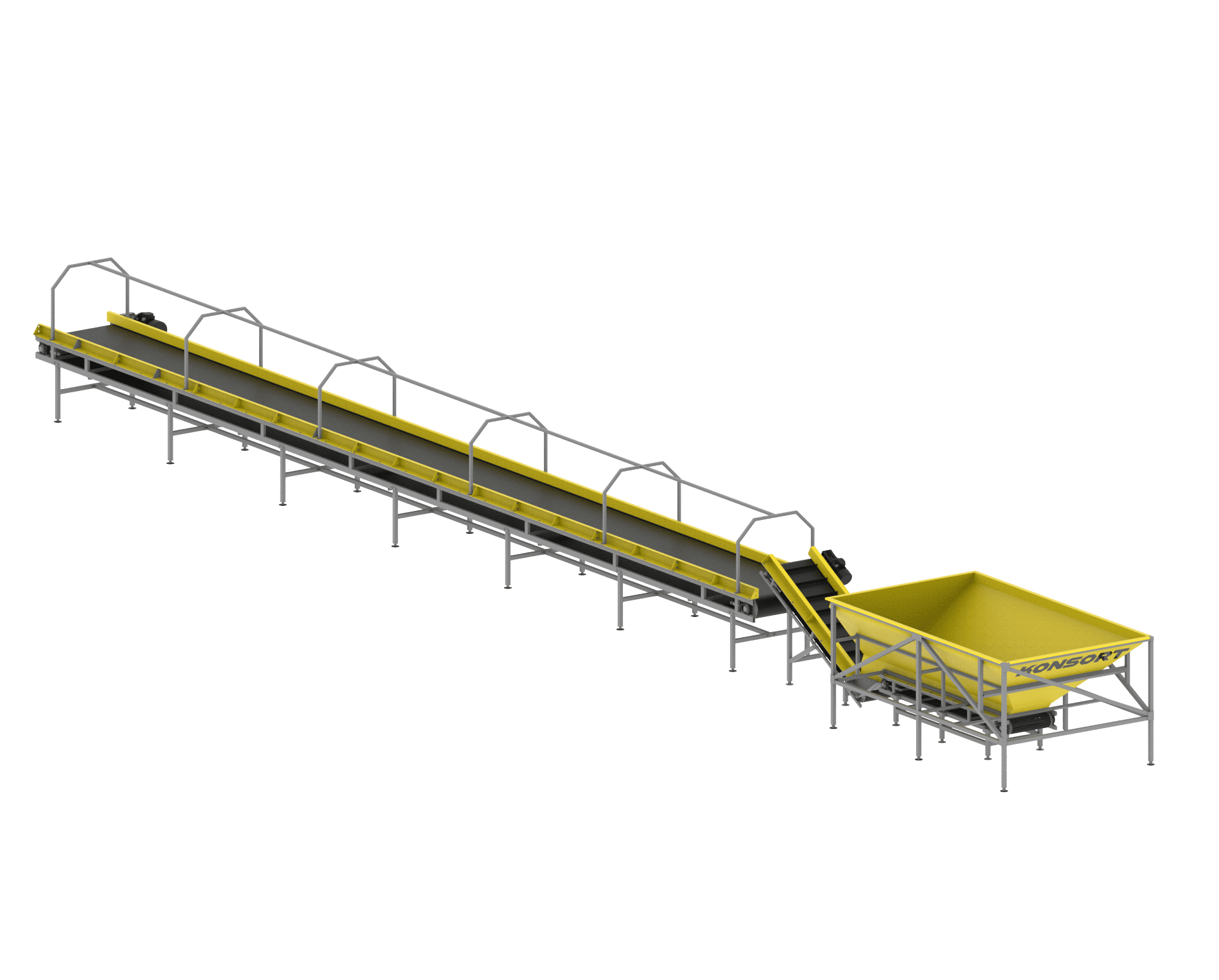

Line for garlic and onion

An automated line for industrial processing of garlic and onions is designed to process agricultural products in the food production cycle. The garlic line equipment is custom-made, in accordance with the required productivity and packaging type specifics of the finished product. This automated equipment makes it possible to process agricultural products at a speed of up to 10 tons per hour.

Technical characteristics:

Overall dimensions

24 700 * 1 600 * 5 000 mm.

Electric power consumption

7kW per hour

Continuous line operation

8 hours

Stop for technical inspection

2 hours

Number of working shifts

2

Number of staff for one shift (8 hours):

Sorting operator

up to 8 people

Line operator

1 person

Loader driver

1 person

Line components:

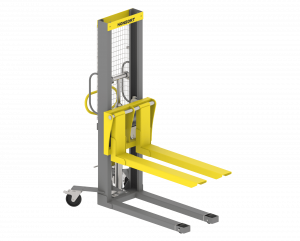

Container tipper

1 unit

Receiving hopper

1 unit

Inclined frame conveyor

1 unit

Bar inspection table

1 unit

Brush roller conveyer

1 unit

Inclined frame conveyor

1 unit

Belt calibrator

1 unit

Turning conveyor with reverse

1 unit

The equipment can be designed according to individual parameters necessary for the customer

Economic advantage:

Improving products quality and grade up to 80%

Improving products quality and grade up to 80%  Productivity increase up to 80%

Productivity increase up to 80%  Lower labour costs up to 65%

Lower labour costs up to 65%  Reduction in human-related risks up to 30%

Reduction in human-related risks up to 30%

Spheres of usage:

- To sort, inspect, and calibrate garlic and onions

Benefits and options:

- European design provides a professional and clean look

- Durable powder coating

- There is possibility to complete the line with extra components if necessary

- Production process is automated

(UA) Про нас говорять

With these products are often ordered