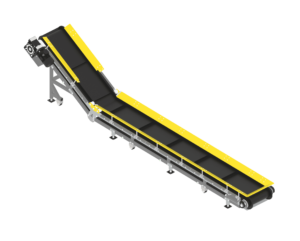

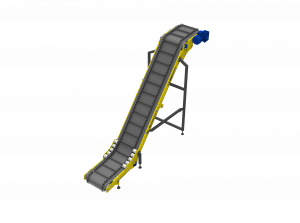

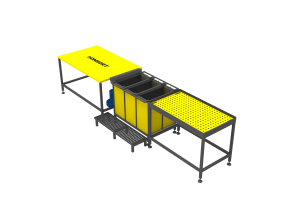

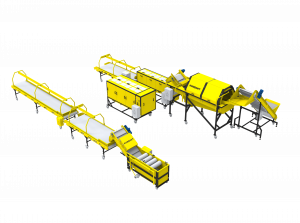

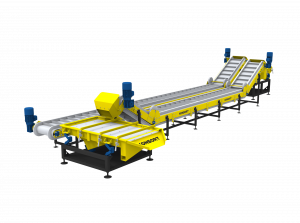

04. Inter-Process Transportation: 50 m Conveyor System for a Food Manufacturer (2 Production Streams)

50-meter food-grade conveyor system merging two production streams into one stable internal logistics flow. Improved efficiency, hygiene compliance, and operational cost optimization.