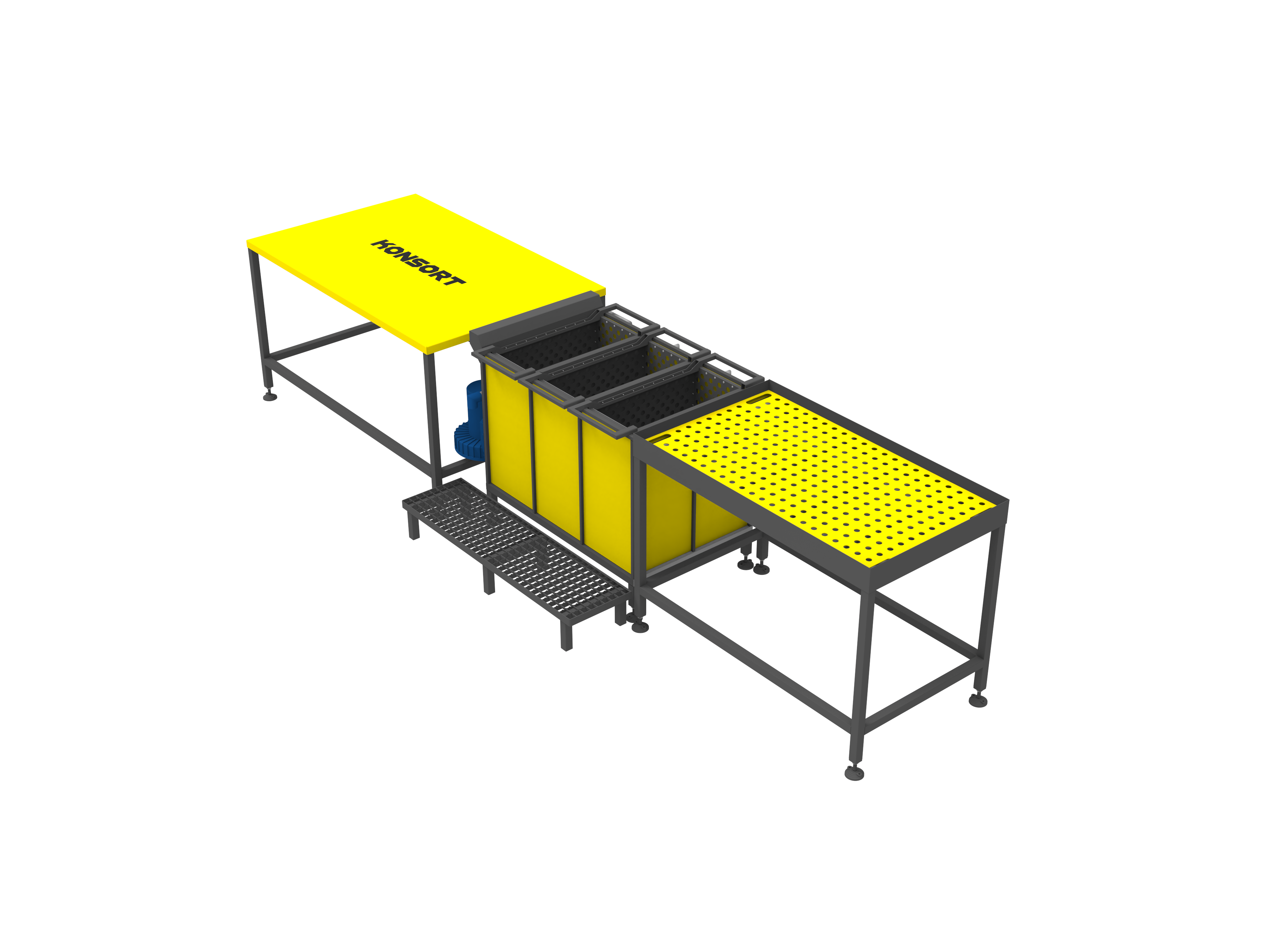

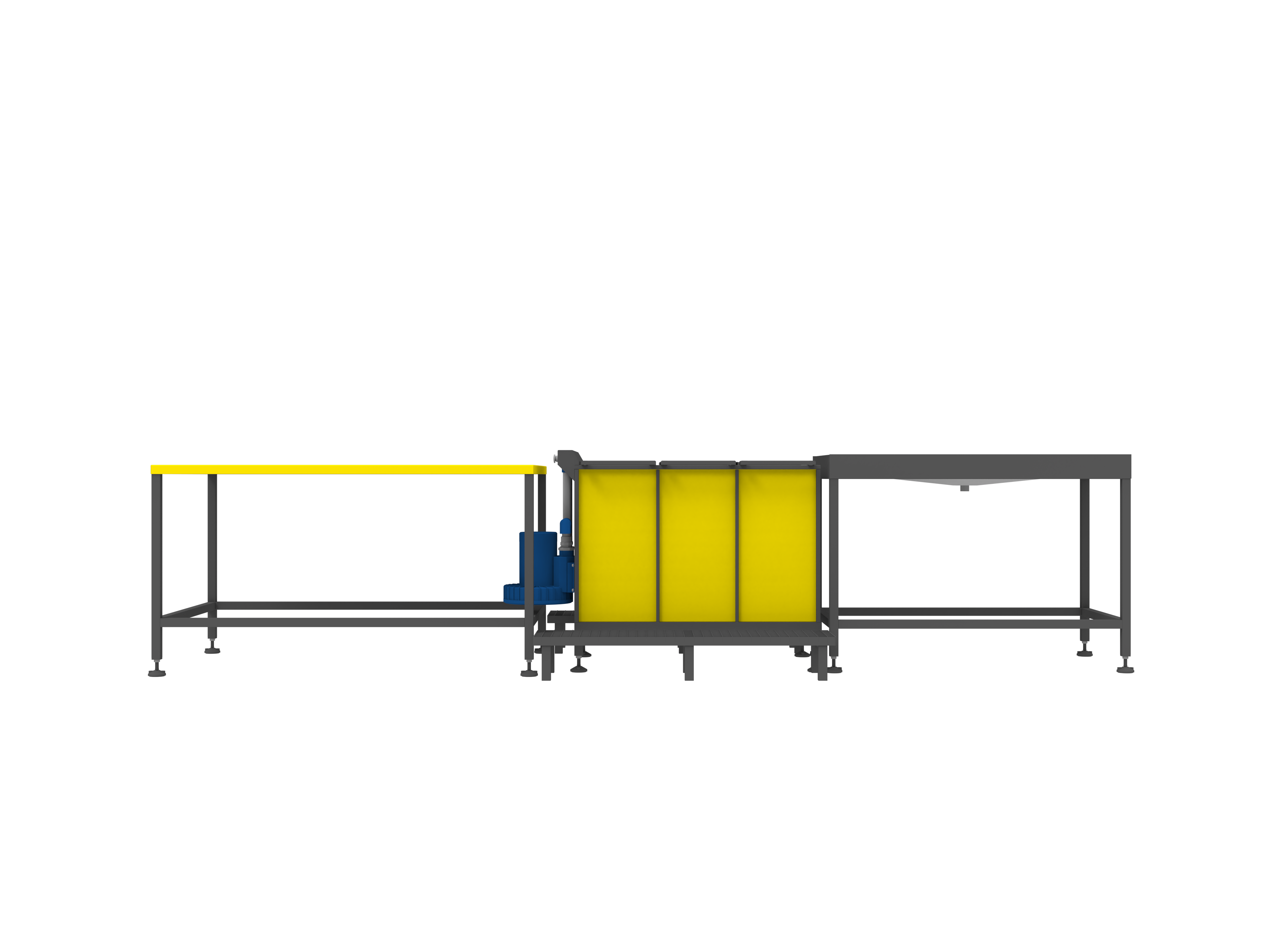

Bubble washer for egg disinfection

The washing machine is designed to disinfect the product (eggs). It is divided by steel partitions into three sections, each of which is sealed and has a separate water drain. When the equipment is started, the bubbling system starts in three sections at the same time.

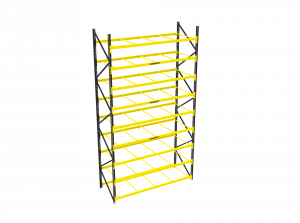

The product (eggs) is packaged in plastic trays and loaded into a mesh shelf. Trays are installed one on one in two rows, 10 units per row. The degree of product washing is determined by the operator. The force of bubbling – air supply – is adjustable. After the product is properly cleaned, the operator moves the shelf to another section of the washing machine. Separately, you can purchase assembly tables and ladders for equipment maintenance. 33P.07.2023

Technical characteristics:

The dimensions of the trays are

300 x 300 x 55/60 mm

Loading shelf -

700 x 650 x 350 mm - 3 pcs

Number of trays in the shelf –

20 pcs

Number of sections -

3,

separation -

wall 1.5 mm thick

Gear motor -

0.75 kW

Control panel -

start/stop buttons

Connection -

380 V

Material of manufacture –

stainless steel AISI 304

Economic advantage:

Improving the washed product quality, reducing damage of raw materials

Improving the washed product quality, reducing damage of raw materials  Productivity increase up to 70%

Productivity increase up to 70%  Workforce optimization up to 30%

Workforce optimization up to 30%  Reduction in human-related risks

Reduction in human-related risks

Spheres of usage:

- Enterprises specialized in pre-sale vegetables and berries preparation

- Enterprises and factories specialized in processing, packing, and freezing products

Benefits and options:

- European design

- Manufacturing process automation, high-quality result

- Thorough and gentle cleaning

- Payback in 9 months

(UA) Про нас говорять

With these products are often ordered