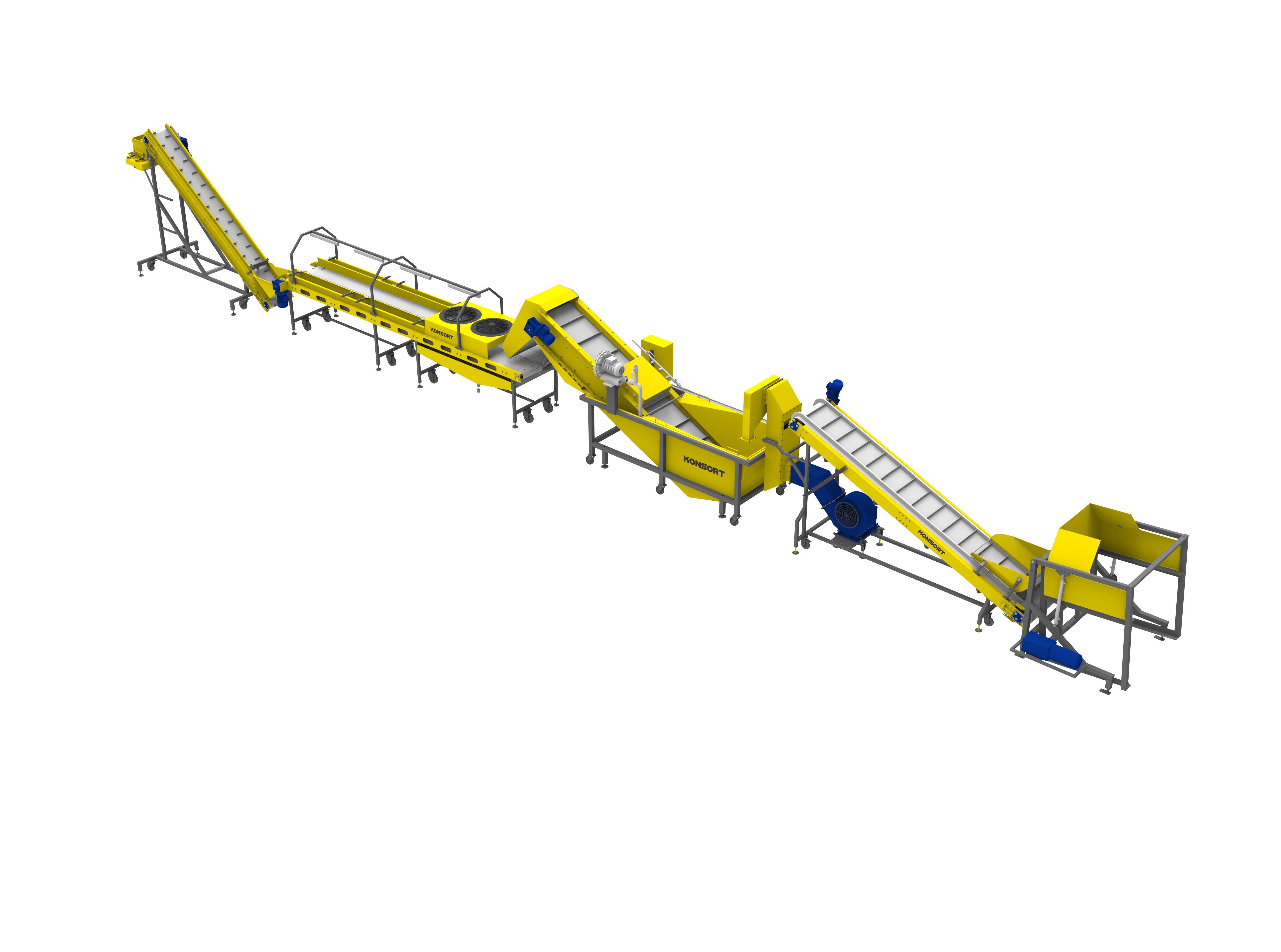

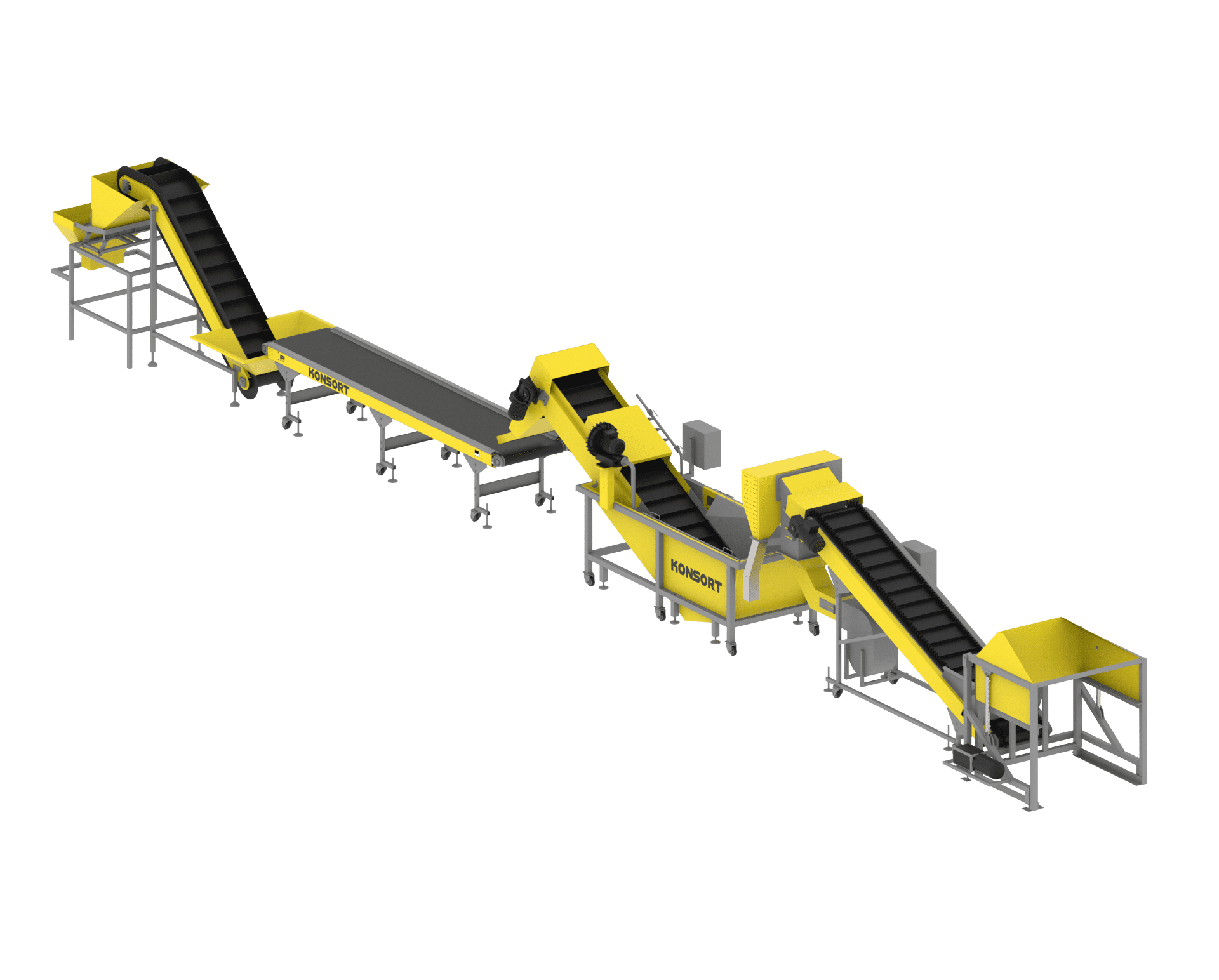

Line for berries

Order a berry processing conveyor line from the manufacturer (Ukraine)

Description

The berry processing line is a modern solution for automating processes in the food industry, designed for efficient transportation, cleaning, washing, preliminary rejection of defective and spoiled products, feeding to freezing, grading, stem removal, final manual sorting of berries, and feeding to packaging. KONSORT equipment helps enterprises significantly reduce manual labor, increase productivity, and minimize the risk of product damage.

Suitable for the following berries: blueberries, highbush blueberries, raspberries, red and black currants, strawberries, cherries, sweet cherries, and plums.

Main components:

- stem remover

- inspection table

- inclined conveyor

- inspection table with drying system

- bubble washer

- belt air separator

- bin tipper

Personnel required per shift:

- sorters — up to 8 people

- line operator — 1 person

- forklift driver or person responsible for container accumulation — 1 person

Advantages:

✅ Customized design — tailored to your production requirements

✅ Versatility — suitable for a wide range of berry products

✅ Gentle transportation — minimizes mechanical damage and preserves berry appearance

✅ Easy integration with other equipment: washers, graders, packaging lines

Order a berry processing line from KONSORT — get reliable, high-performance, and durable equipment that will optimize your processes, reduce costs, and increase your enterprise’s profitability!

Improving products quality and grade up to 80%

Improving products quality and grade up to 80%  Productivity increase up to 80%

Productivity increase up to 80%  Lower production costs up to 40%

Lower production costs up to 40%  Reduction in human-related risks up to 20%

Reduction in human-related risks up to 20% - Berry processing, freezing and packaging enterprises

- Manufacturers of frozen semi-finished products and confectionery

- Agro-industrial complexes and farms

- European design provides a professional and clean look

- Suitable for a wide range of berries

- There is possibility to complete the line with extra components if necessary

- Production process is automated