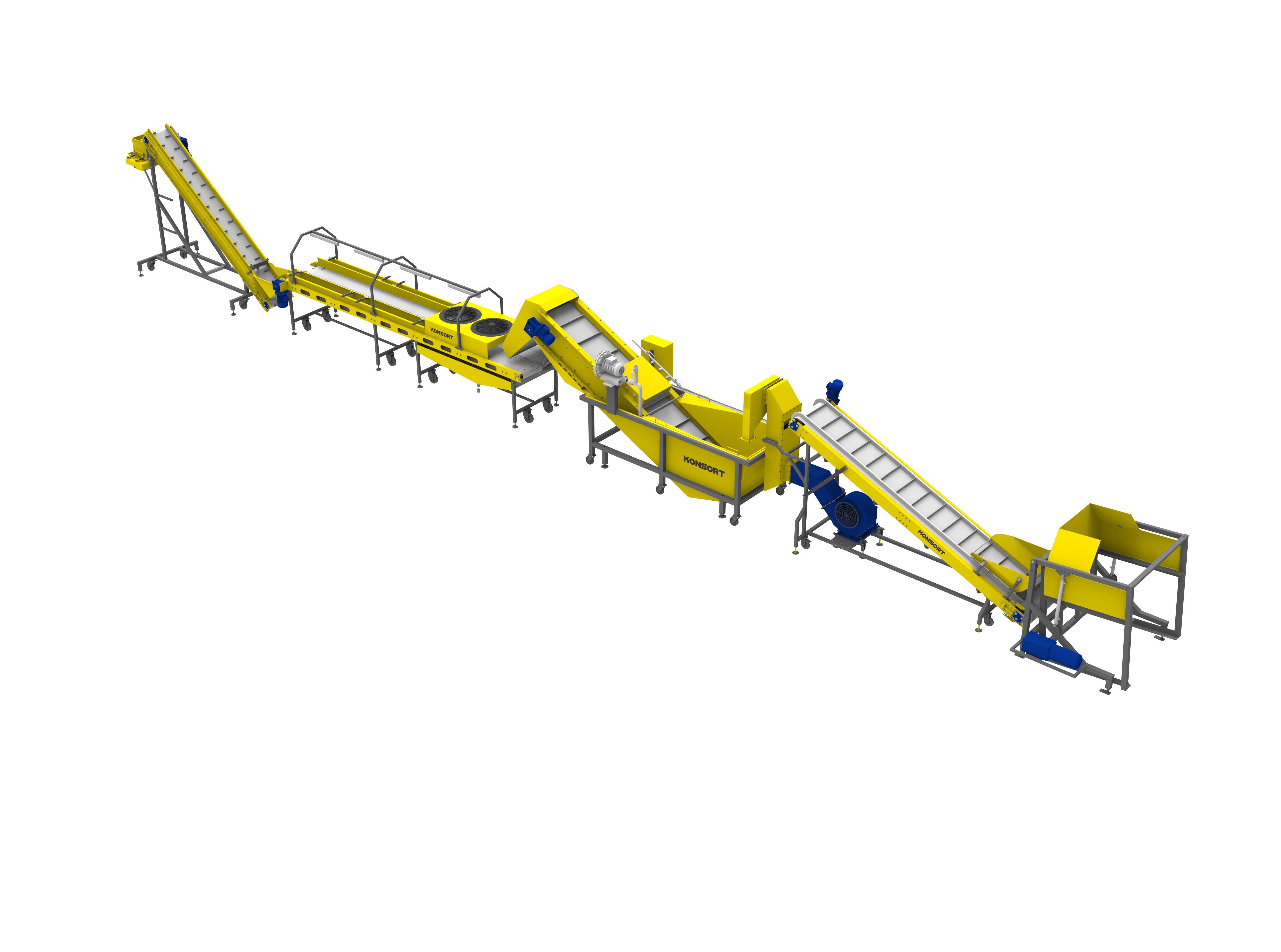

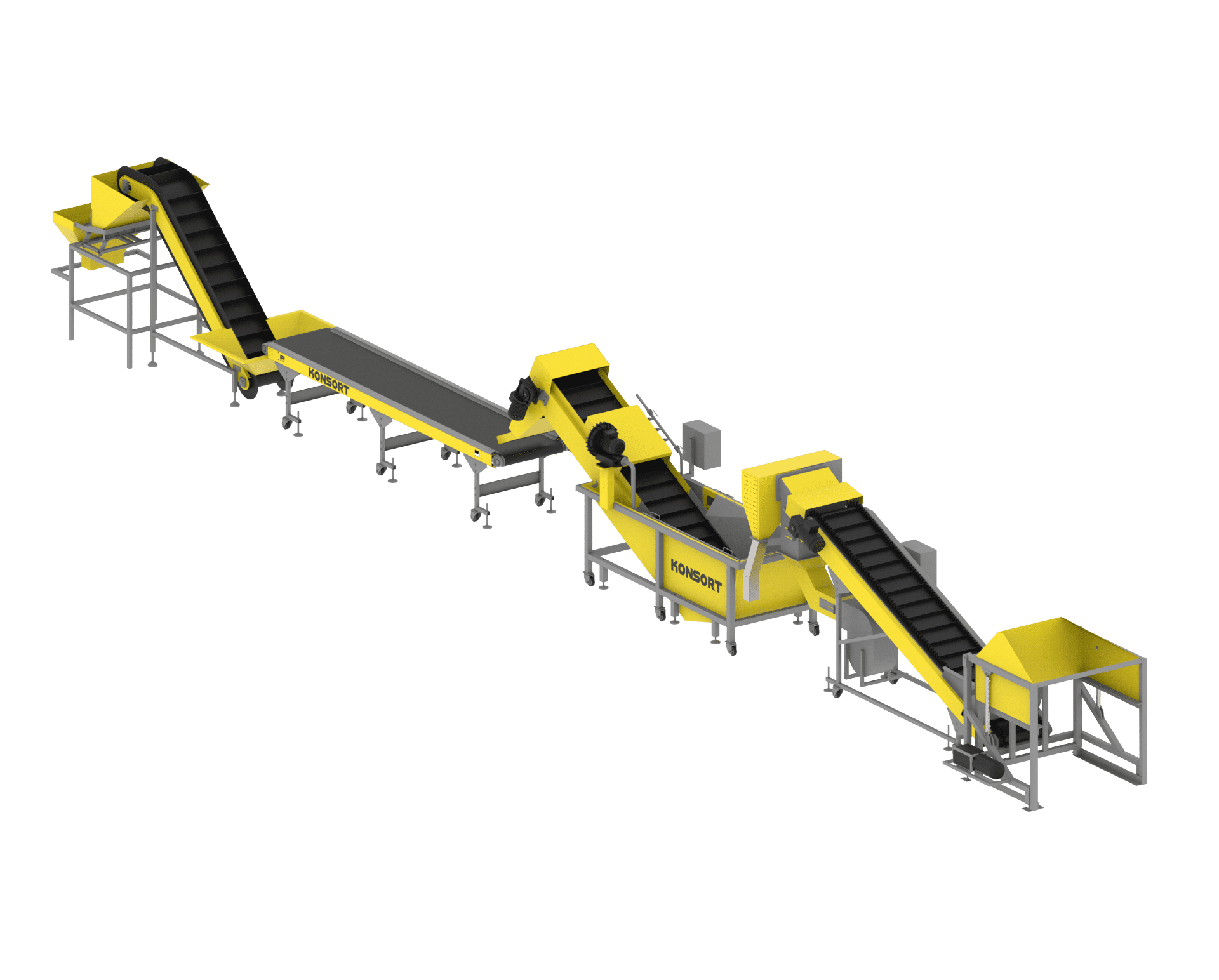

Line for berries

This line is designed to freeze berries and its total productivity is 3 tons per hour. The line includes such stages as peeling, washing, previous selection of defective and spoiled products, delivery for freezing, calibration, separation of stems, final manual sorting of berries and delivery for packing. It is also possible to include into the line the ability to move finished products across the warehouse. The material for the equipment can be combined in some sections, depending on your needs. This line is suitable for such berries as blueberries, raspberries, red and black currants, strawberries, cherries, sweet cherries and plums.

Technical characteristics:

Productivity

1-5 tons per hour

Electric power consumption

8kW per hour

Continuous line operation

8 hours

Stop for technical inspection

2 hours

Number of working shifts

2

Number of staff for one shift (8 hours):

(UA) до 8 чоловік

Sorting operator

up to 8 people

Line operator

1 person

Loader driver

1 person

Line components:

Container tipper

1 unit

Tape winnower

1 unit

Bubble washer

1 unit

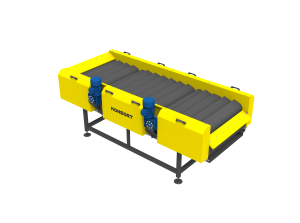

Inspection table with drying system

1 unit

Inclined conveyor

1 unit

Stem separator

1 unit

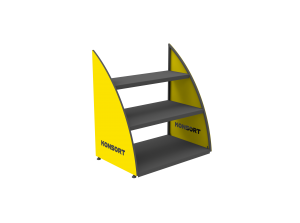

Inspection table

1 unit

The equipment can be designed according to individual parameters necessary for the customer

Economic advantage:

Improving products quality and grade up to 80%

Improving products quality and grade up to 80%  Productivity increase up to 80%

Productivity increase up to 80%  Lower production costs up to 40%

Lower production costs up to 40%  Reduction in human-related risks up to 20%

Reduction in human-related risks up to 20%

Spheres of usage:

- To sort, inspect, calibrate, and wash fruit, berries and some vegetables

Benefits and options:

- European design provides a professional and clean look

- The equipment is designed in accordance with all the rules and regulations put forward to the food industry equipment

- There is possibility to complete the line with extra components if necessary

- Production process is automated

(UA) Про нас говорять

With these products are often ordered