02. Sorting and packaging of products

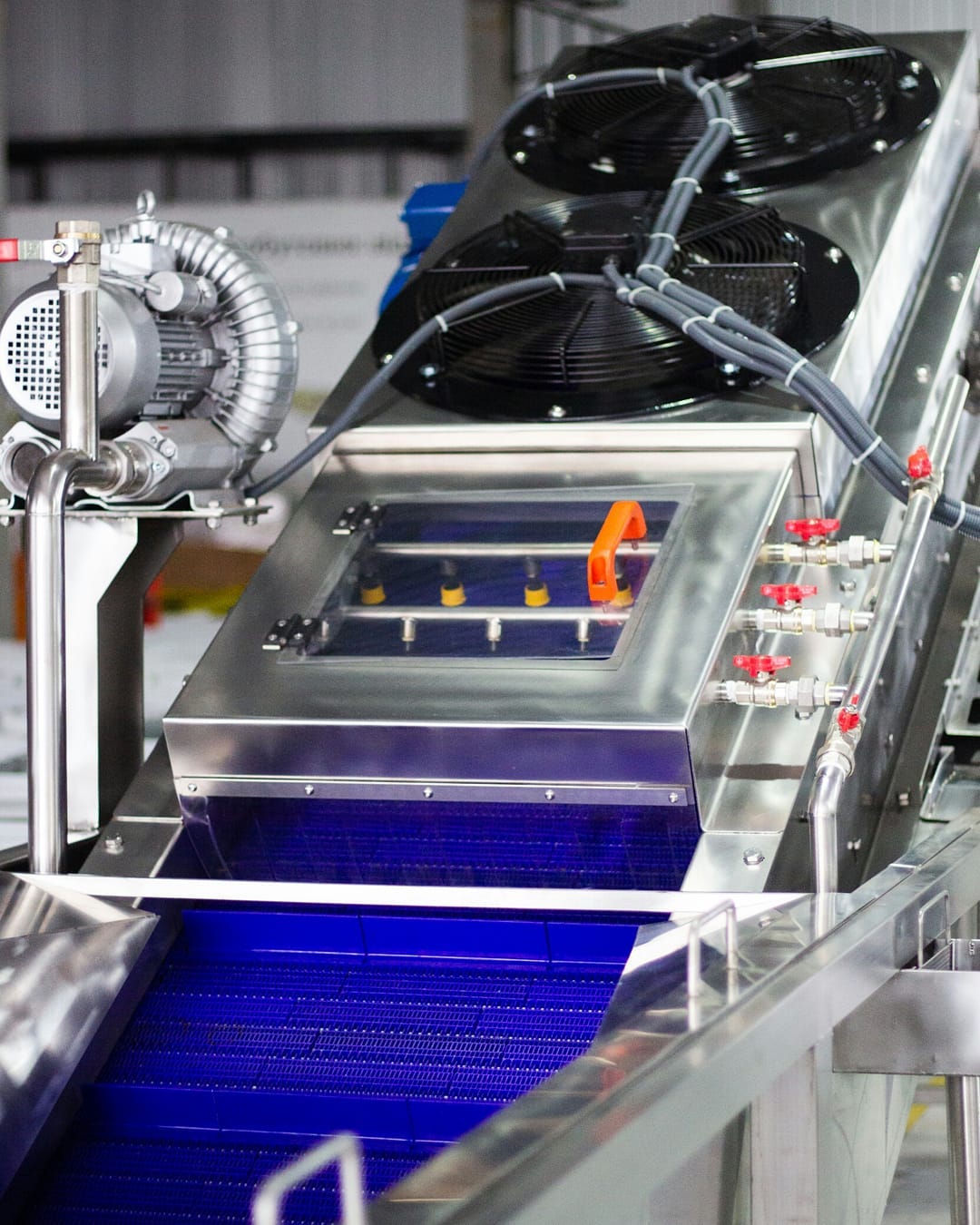

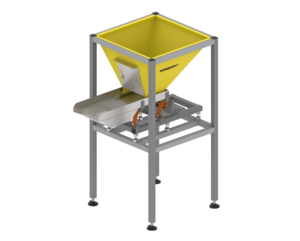

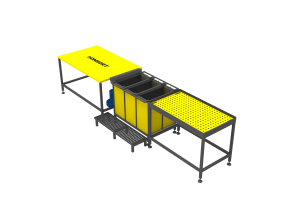

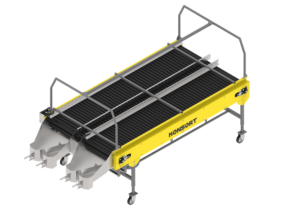

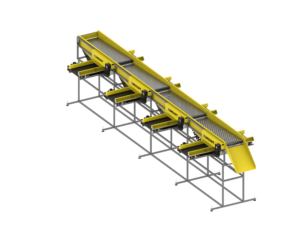

The implementation of automated conveyor systems for sorting and packaging agricultural products helps enterprises significantly improve the efficiency and quality of their processes. Product sorting is performed mechanically using specialized belt conveyors and calibration equipment.