Line for sorting solid waste 50 000 tons per year

Order a Municipal Solid Waste Sorting Line up to 50,000 tons/year from the manufacturer (Ukraine)

Description

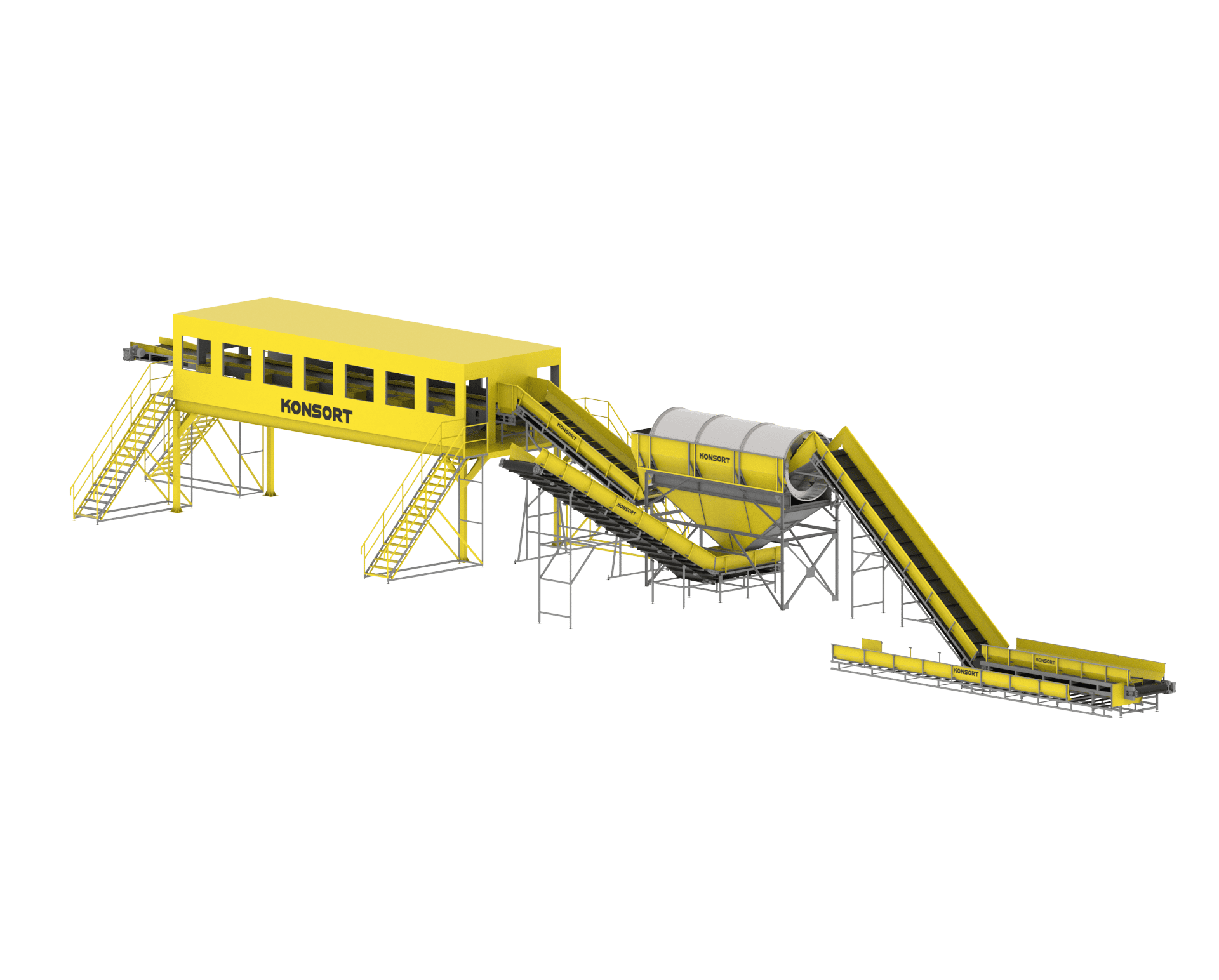

The Municipal Solid Waste (MSW) Sorting Line with a capacity of up to 50,000 tons per year is a modern integrated solution for enterprises aiming to improve waste recycling efficiency, minimize environmental impact, and reduce waste processing costs.

The system is designed to extract valuable recyclable materials from the MSW stream and send them for further processing.

Operating principle:

Waste is fed into a receiving pit equipped with an L-shaped conveyor, which transfers it to a trommel drum separator. The mesh drum with an integrated bag-tearing system separates the fine fraction (organics, soil) and conveys it to a dedicated container.

The sorted fraction is transported via an inclined conveyor to the sorting room, where recyclable materials are manually separated on an inspection conveyor. At the end of the line, an automatic magnetic separator removes ferrous metals into a separate container. Residual waste is collected in containers located beneath the sorting area.

Components:

- inclined conveyor with pit – 2 pcs

- drum separator – 2 pcs

- discharge conveyor – 2 pcs

- inclined conveyor

- inspection conveyor (sorting) for 12 operators

- ferrous metal separator (magnetic separator)

- tailings discharge conveyor

- recyclable waste selection room

- containers for collecting sorted MSW from under the operator cabin

Personnel:

- sorters – 8 or 12 persons

- mechanic – 1 person

- power engineer – 1 person

- line supervisor – 1 person

- driver – 1 person

Environmental efficiency and economic benefits:

✅ Optimised operational costs by reducing waste disposal and transportation expenses.

✅ Reduced landfill waste volumes and environmental impact.

✅ Increased recycling rates and more efficient resource utilisation.

Order the KONSORT MSW Sorting Line (up to 50,000 tons/year) today and make your contribution to a cleaner environment and more efficient production!

Improving products quality and grade by 90%

Improving products quality and grade by 90%  Productivity increase up to 80%

Productivity increase up to 80%  Lower production costs by 40%

Lower production costs by 40%  Reduction in human-related risks by 30%

Reduction in human-related risks by 30% - Municipal enterprises — for sorting mixed waste prior to disposal

- At landfills or at specially constructed plants for shredding and sorting waste

- European design provides a professional and clean look

- Environmental improvement

- There is possibility to complete the line with extra components if necessary

- Automatic line control (start and stop of a specific technological process is provided)

- Installation of video surveillance

- Sound and light alarm