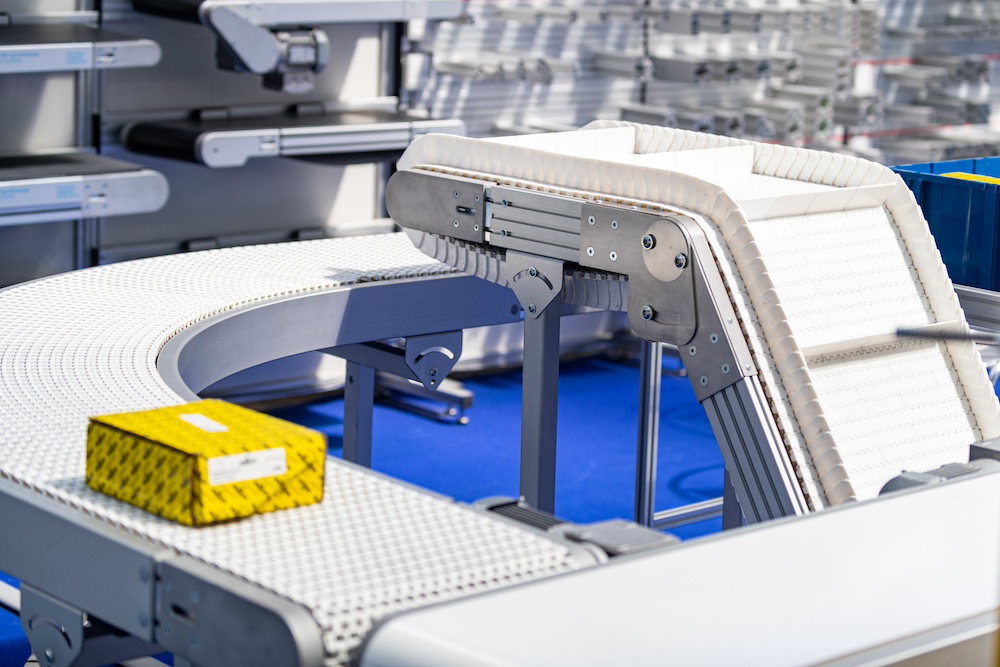

Roller conveyors: efficiency and versatility in transporting goods

Roller conveyors are an important element in transportation and logistics systems. Their application is very wide, from warehousing to production, thanks to the number of advantages they offer.

01. Design and principle of operation of the roller conveyor:

The roller conveyor consists of a number of cylindrical roller conveyors that move along a special structure. These roller blinds are securely fixed and driven by motors or manual mechanisms. The goods are placed on roller conveyors, and their movement occurs due to the movement of the roller conveyors.

Roller conveyors are a wide variety of conveyors that use roller blocks to transport goods. These conveyors have different designs and applications depending on specific production or logistics needs. Here are some basic types of roller conveyors:

- Power roller conveyor:

Description: This type of conveyor includes roller blocks that are driven by motors. They are often used to transport heavy or large loads.

Application: Production, distribution of large goods, automotive industry.

- Gravity roller conveyor:

Description: The roller blocks of this conveyor move under the influence of gravity, without the use of an additional mechanical drive. Usually used for unloading goods.

Application: Warehousing, sorting centers, packaging lines.

- Sectional roller conveyor:

Description: Consists of a number of shorter sections that can be joined together or separated depending on production needs.

Application: Production, distribution, warehousing.

- Accumulating roller conveyor:

Description: Roller units can automatically stop or accumulate goods at specific locations, allowing efficient control of material flow.

Application: Packaging lines, sorting systems.

- Lifting roller conveyor:

Description: Uses roller blocks to move goods up or down at an angle. It is often used to supply materials to production lines.

Application: Automotive industry, electronics manufacturing.

- Flexi-roller (flexible) conveyor:

Description: Has flexible sections that can be bent and change the direction of the conveyor, which facilitates adaptation to various spatial conditions.

Application: Sorting areas, logistics centers.

- Storage and transport roller conveyor:

Description: Combination of storage and transport functions for efficient material flow management.

Application: Mass production, warehousing.

The choice of a specific type of roller conveyor depends on the nature of production, the size and weight of the transported goods, as well as on the specific requirements and conditions of your enterprise.

02. Areas of use of roller conveyors:

- Warehousing: Roller conveyors are widely used for placing and transporting goods in warehouses. Their efficiency in managing light and medium loads makes them indispensable for optimizing logistics processes.

- Production: In production lines, roller conveyors are used to move products between different stages of the production process. They ensure efficiency and reliability of transportation.

- Trade and distribution: In supermarkets and shopping centers, roller conveyors can be used to move goods from the storage area to the checkout lines, providing fast and efficient customer service.

Roller conveyors solve a number of important tasks in various fields of production and logistics due to their features and advantages. Here are some of the tasks they effectively solve:

Transportation of goods:

Task: Efficient movement of goods from one point to another without unnecessary efforts of employees.

Optimization of logistics processes:

Task: Ensuring the efficient movement of goods in warehouses, on production lines or in warehouses of goods.

Acceleration of order processing:

Task: Reducing the time for processing and sending orders, which is critical in the modern logistics environment.

Maneuverability and flexibility:

Task: Ensuring the ability to adapt conveyors to various types of goods and sizes.

Saving working space:

Task: Using the limited production or warehouse space as efficiently as possible due to the compactness of roller conveyors.

Supply of materials to the production line:

Task: Transfer of raw materials or components to production lines for further processing or assembly.

Material flow management:

Task: Ensuring control over the movement of materials, which is important for the accuracy and efficiency of production.

Ensuring security:

Task: The possibility of built-in mechanisms to stop or block the conveyor to avoid accidents and ensure the safety of personnel.

Mass transport of light goods:

Task: Efficient transportation of light goods, such as boxes, packages, or packaged goods.

Quality control:

Task: The possibility of integrating quality control systems on conveyors to detect defects or malfunctions of goods.

Roller conveyors effectively solve these tasks due to their simplicity, reliability and adaptability to different production conditions.

03. Advantages of roller conveyors:

- Efficiency: Roller conveyors allow you to efficiently transport goods from one point to another, reducing the time and effort of movement.

- Reliability: Steel rollers and solid construction make these conveyors reliable and durable.

- Flexibility: The ability to easily adapt to different sizes and types of goods makes them excellent for a variety of tasks.

There are several alternative solutions that can be used as competitors or alternatives to roller conveyors. The choice of the optimal solution depends on specific requirements and production conditions. Here are some alternative transportation systems:

- Belt Conveyors:

Description: Belt conveyors use rubber or metal belts to transport goods. They are effective for transporting large volumes of goods, especially heavy or unevenly distributed ones.

Application: Mass production, copal, mining industry. - Pneumatic Transport Systems:

Description: Goods are transported using air flow. It is effective for light or powdery materials.

Application: Food industry, chemical industry, pharmaceuticals. - Suspended Conveyors:

Description: Goods are moved, suspended on chains or cables, which allows them to move along the production space.

Application: Automotive industry, pharmaceuticals, production of heavy products. - Power Conveyors with Moving Belt Sliding:

Description: Power rollers are used to transport goods. This can be effective for transporting heavy or irregularly shaped goods.

Application: Furniture production, material processing. - Vibrating Conveyors:

Description: Uses vibrations to move materials. This can be effective for small, wet or sticky goods.

Application: Food industry, pharmaceuticals, agriculture. - Conveyors with Plate Feeding:

Description: Special plates are used for transporting goods. Can be effective for small or non-uniform materials.

Application: Packaging, sorting, production of light goods.

Roller conveyors are considered the most optimal solution due to their efficiency, reliability and flexibility, which allows for the efficient transportation of goods of various types in various fields of production and logistics. But each type of conveyor has its advantages and disadvantages, and the choice of a specific solution should take into account the specific needs and conditions of your production.

04. Why should you buy a roller conveyor?

Purchasing a roller conveyor for your business can lead to numerous benefits and improvements in the production process. Here are some key arguments why it could be beneficial:

- Productivity improvement:

Roller conveyors allow you to efficiently transport goods without significant expenditure of time and effort, which contributes to increasing the overall productivity of production. - Optimization of logistics processes:

The use of conveyors facilitates logistics operations, reducing the time for moving goods and facilitating the work of personnel. - Increased flexibility and adaptability:

Roller conveyors allow you to easily adapt the transportation system to different types of goods and production conditions, ensuring flexibility in work. - Saving working space:

The compact design of roller conveyors allows efficient use of limited production space, which is especially important in conditions of limited space. - Reduction of labor costs:

Automating transportation with conveyors helps to reduce the dependence on manual labor, which can lead to savings in labor time and labor costs. - Possibility of integration with other systems:

Roller conveyors can be easily integrated with other automated production or logistics systems, which facilitates the management and control of production processes. - Increasing the level of security:

Built-in safety systems on conveyors help avoid accidents and unplanned stops, providing safe conditions for personnel. - Ensuring quality control:

The ability to use conveyors to transport goods through quality control points helps improve product quality and avoid defects.

By choosing a roller conveyor, your company can get not only improvements in efficiency, but also the ability to easily adapt to changes in production and market conditions. To buy a roller conveyor Ukraine – contact us for a free expert consultation: +38 (067) 116-50-25

Conclusion: Roller conveyors are a key component in solving transportation and logistics tasks. Their efficiency, reliability and flexibility make them an important tool for increasing productivity and optimizing work processes in various fields of activity. To choose a reliable option, contact the manufacturer KONSORT directly, with 17 years of experience and more than 4,000 projects.