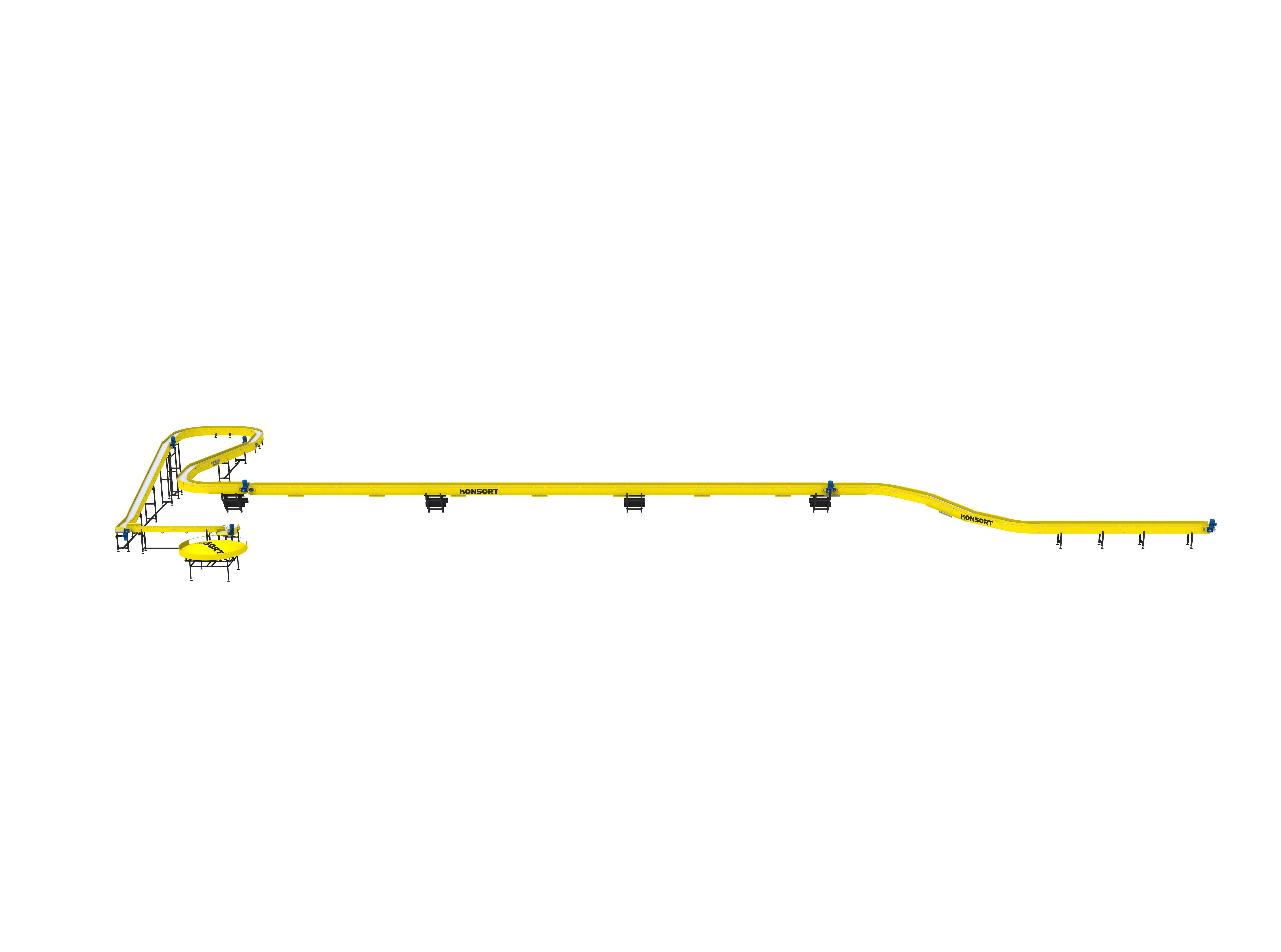

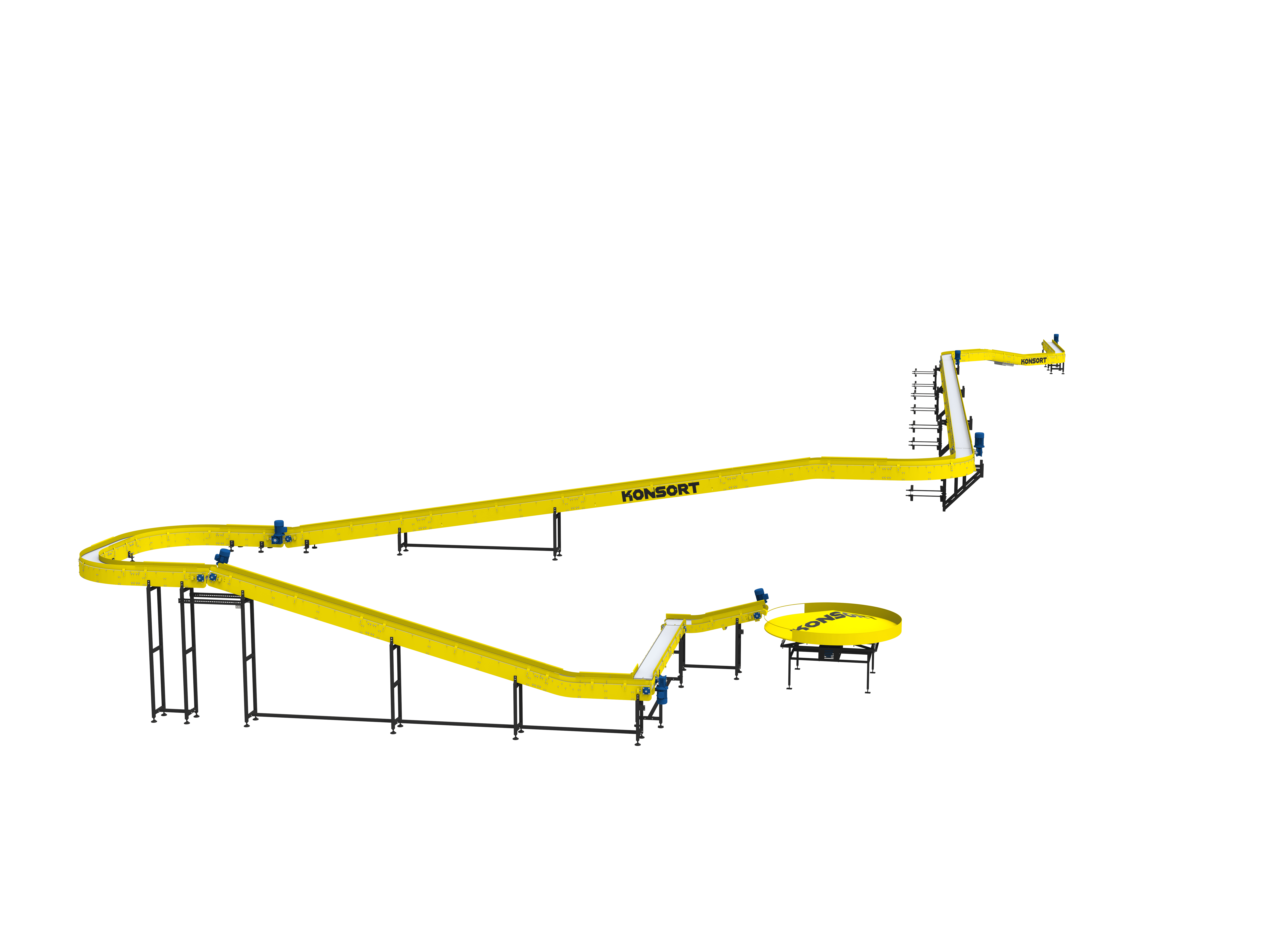

Bread transportation line

Buy a bread transport line from the manufacturer (Ukraine)

Description

The bread transport line is designed for the automated transfer of freshly baked bread from the oven to the spiral conveyor for further cooling. At the oven exit, the bread temperature reaches approximately 100 °C; therefore, the conveyor system is equipped with a heat-resistant food-grade belt that ensures safe and efficient product transportation.

The line allows for the even distribution of bread without the risk of damage or interruptions in the production process. Thanks to the use of a turn conveyor and a rotary table, optimal product flow logistics are ensured.

Main components:

✅ Turn Conveyor – for changing the direction of product movement

✅ Bread Transfer Conveyor – for moving bread to the cooling conveyor

✅ Stationary Belt Conveyor – for stable bread transportation

✅ Rotary Table – for even product distribution

Advantages of the bread transport line:

- High temperature resistance of the belt

- Automated bread handling and transfer

- Continuous and uninterrupted product flow

- Minimal risk of bread damage

- Optimal integration into production lines

Why choose a bread transport line from KONSORT?

- Manufactured in Ukraine – we design, produce, and test our equipment in-house

- Direct-from-manufacturer pricing – no dealer markups

- Warranty & Service – full service support, commissioning, and staff training

- Custom solutions – tailored dimensions and features to meet your production needs

- Exported to 18+ countries – internationally proven quality

How to order a b read transport line

To order a bread transport line for your production:

- Submit a request via our website or call us directly.

- Confirm technical specifications and delivery terms.

- Receive the finished equipment with delivery and optional installation.

Order your bread transport line directly from the manufacturer – ensure a smooth, uninterrupted production and transportation process for your products!

Improving in the organization of production and management by 65%

Improving in the organization of production and management by 65%  Productivity increase up to 60%

Productivity increase up to 60%  Lower labour costs by 78%

Lower labour costs by 78%  Reduction in human-related risks by 40%

Reduction in human-related risks by 40% - Bakeries

- Food industry

- Automated lines for bakery product manufacturing

- European design provides a professional and clean look

- Durable powder coating

- There is possibility to complete the line with extra components if necessary

- European components are used