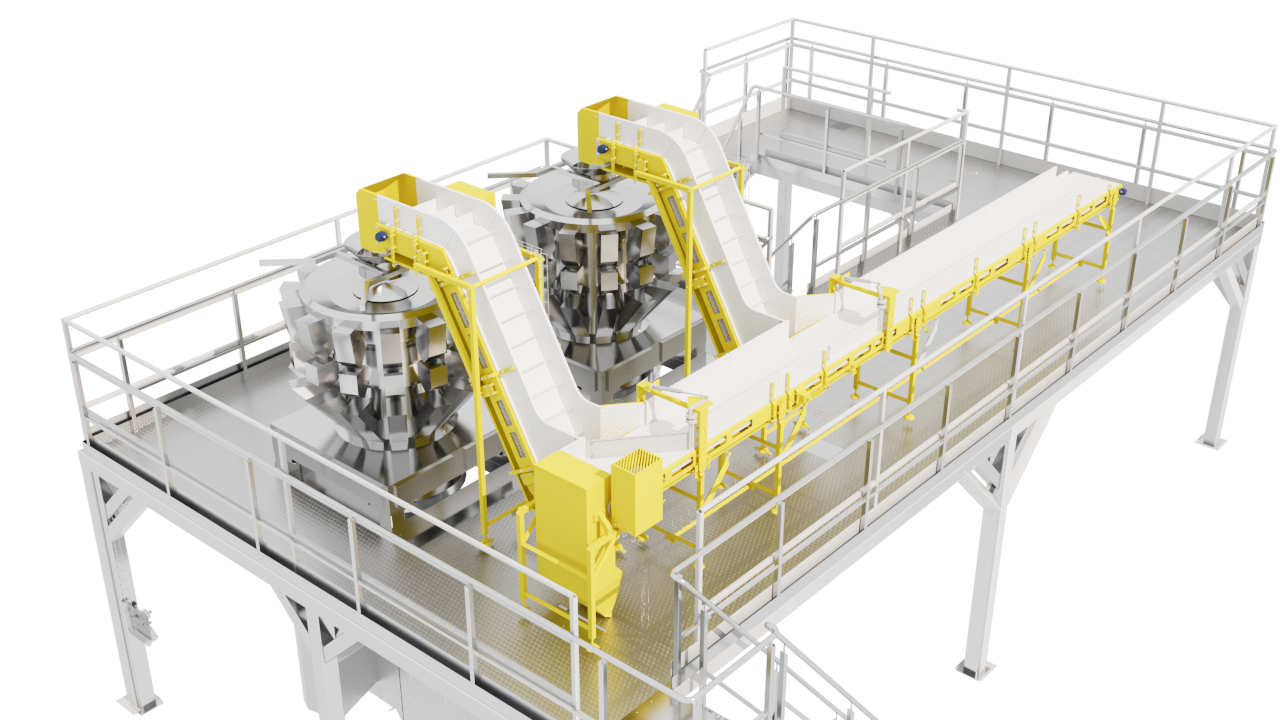

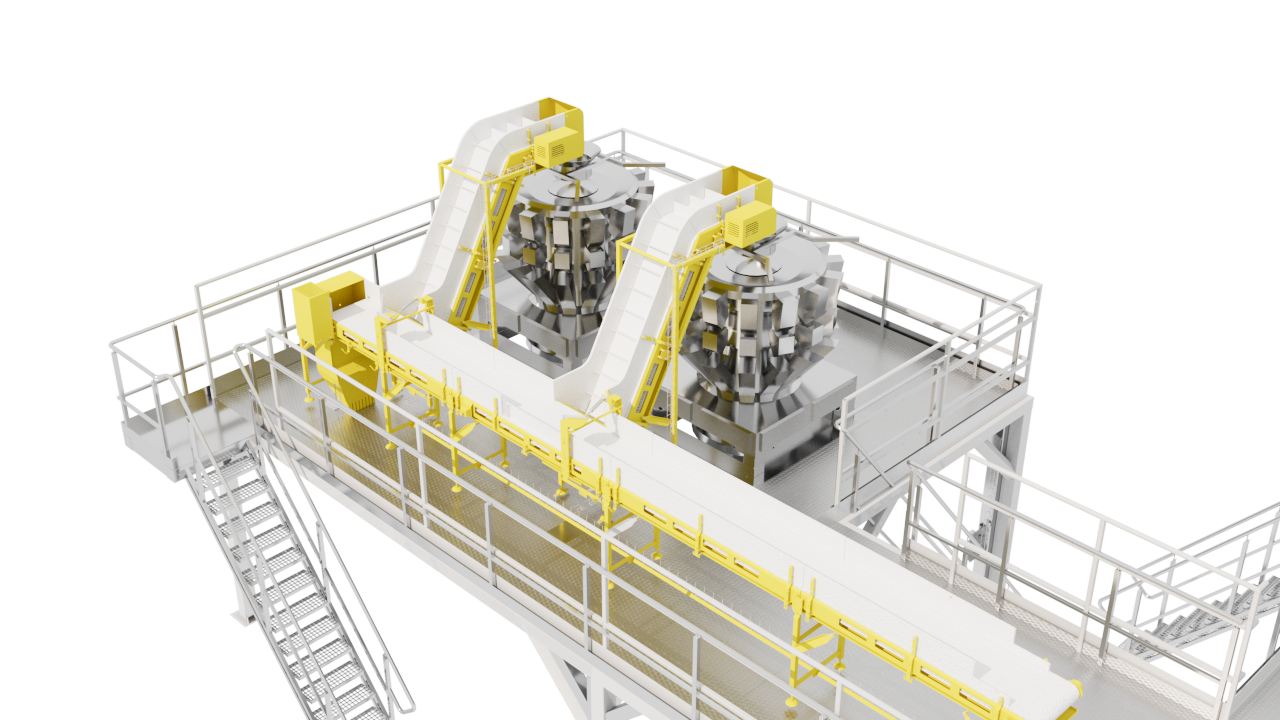

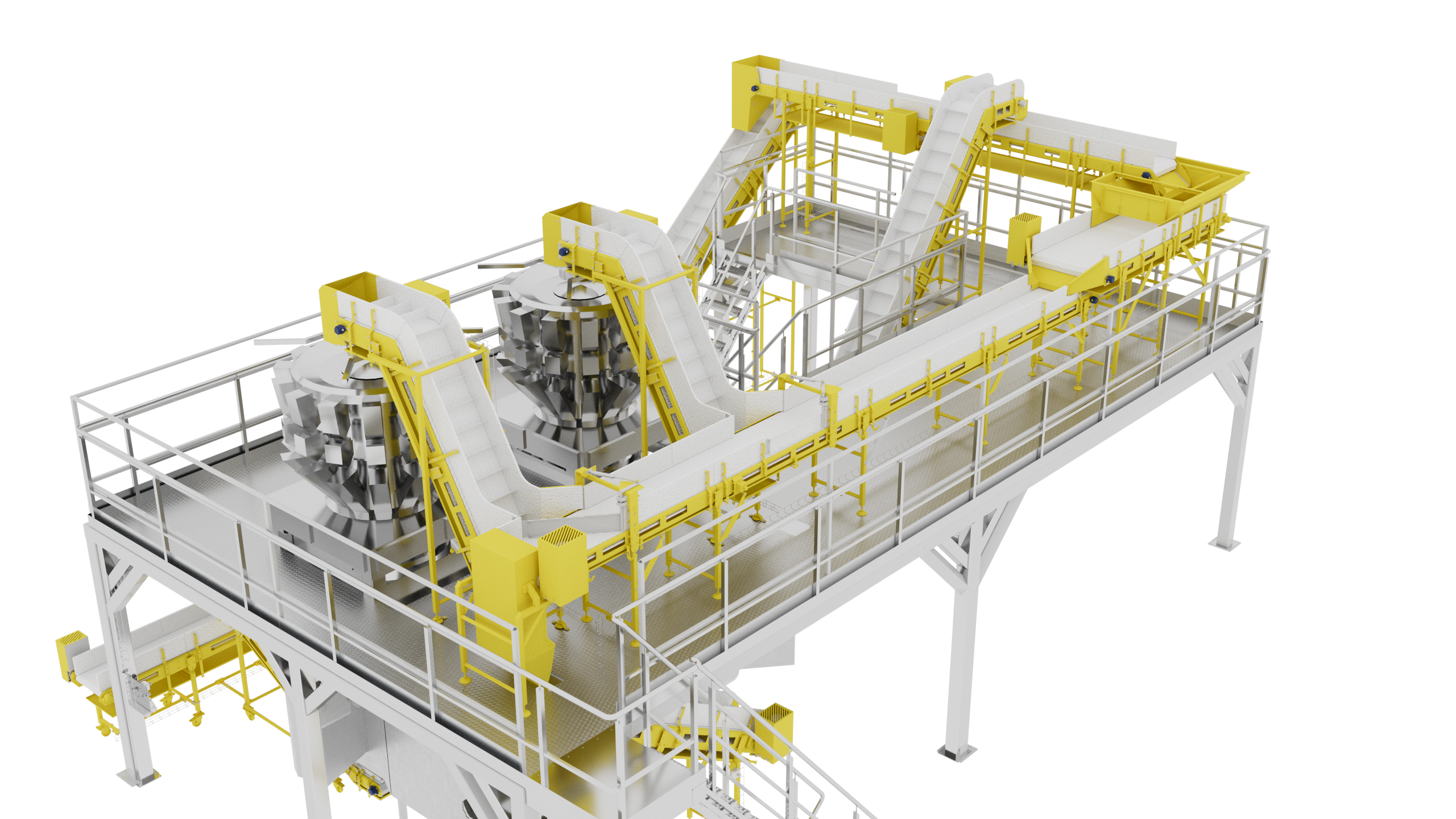

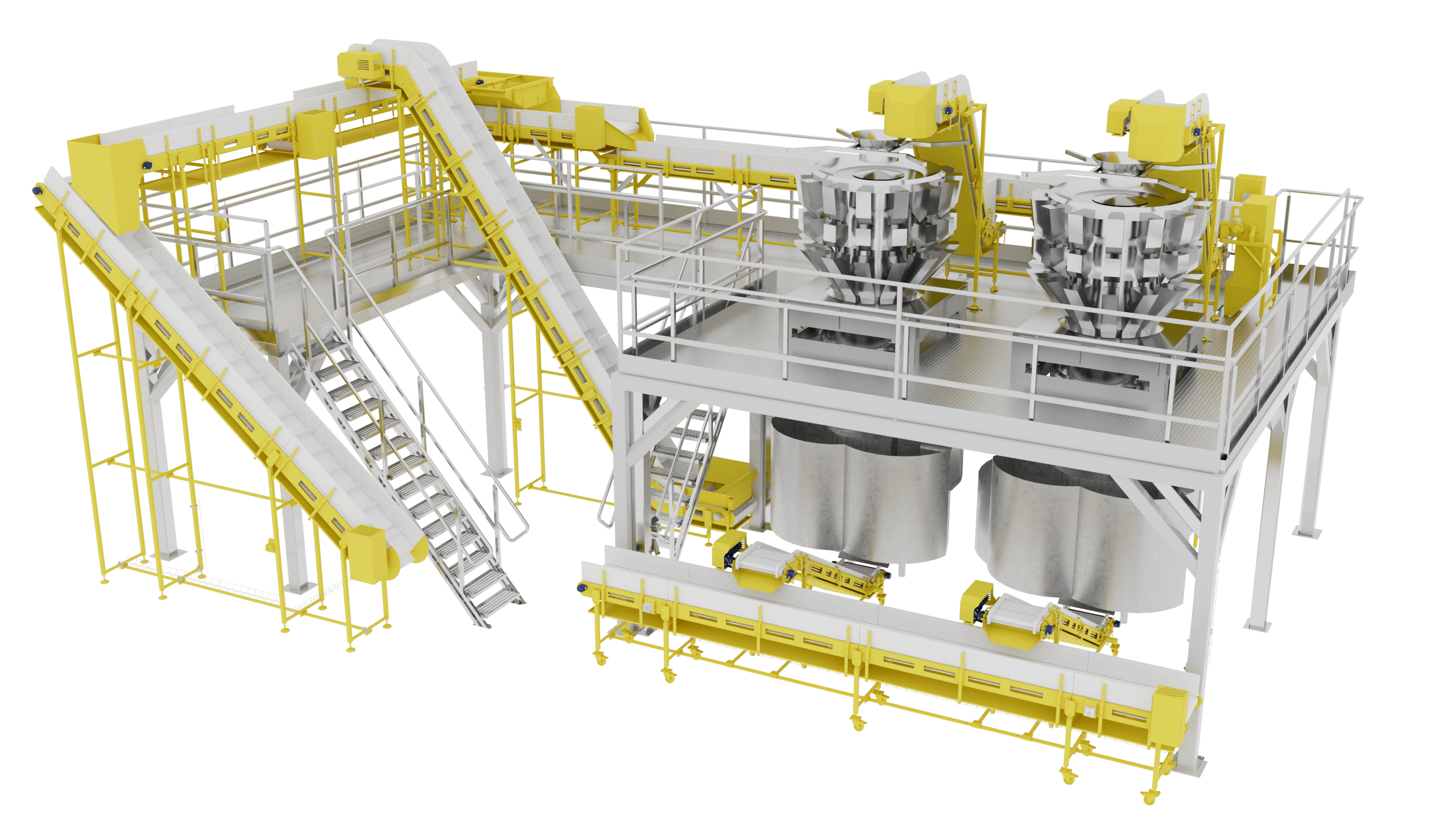

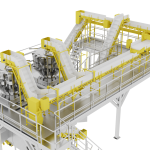

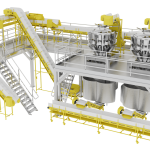

Conveyor line for semi-finished products

Order a conveyor line for semi-finished products from the manufacturer (Ukraine)

Description

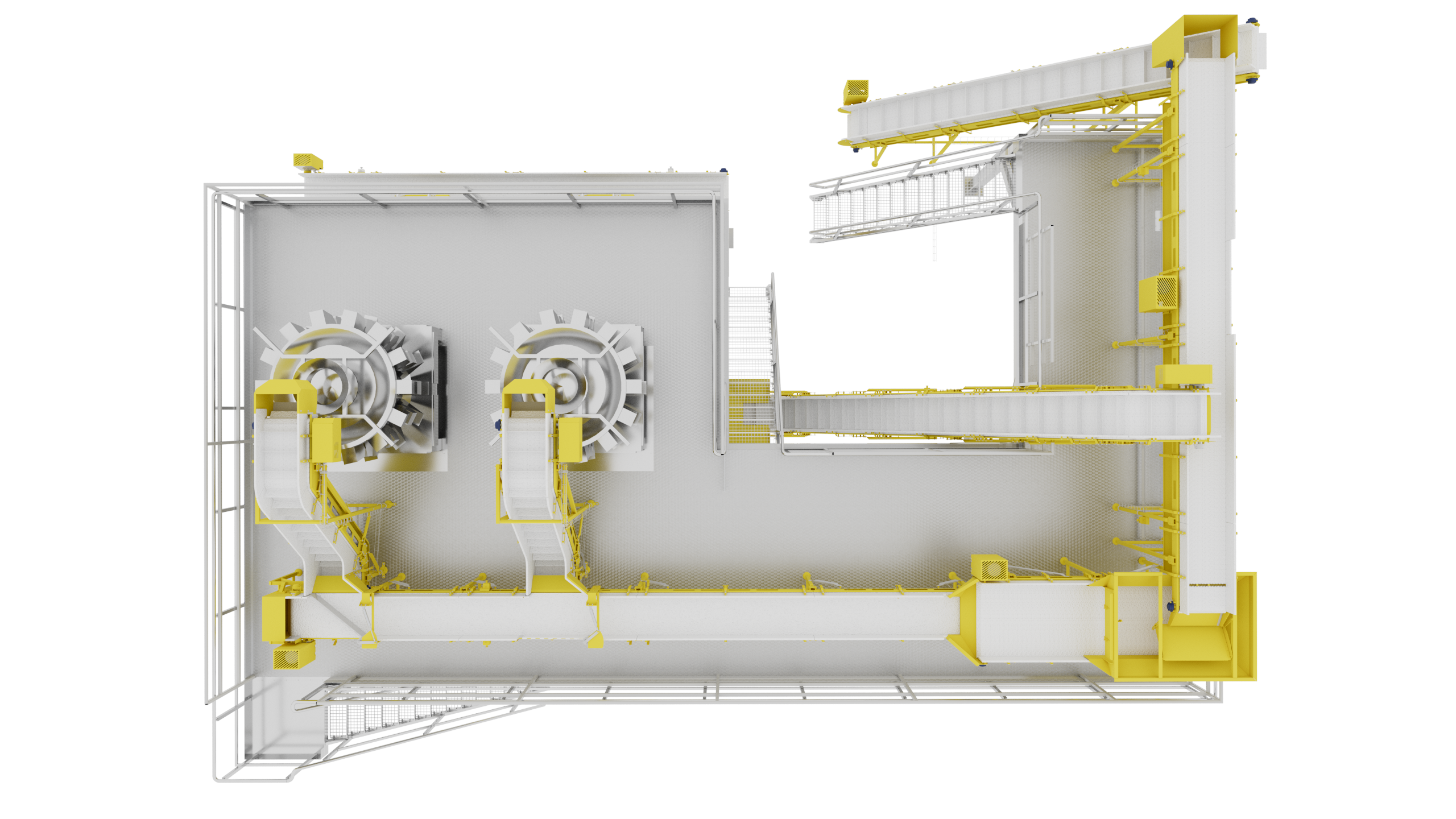

The semi-finished product processing line is a high-tech solution from the manufacturer, designed to optimise production processes in the food industry. This system is ideal for transporting products, changing the direction of product flow, sorting, feeding into packaging, and other processing stages of semi-finished products.

Thanks to its modular design, the line can be easily integrated into existing packaging lines, providing flexibility and scalability for production.

The equipment is manufactured in compliance with BRC food safety standards.

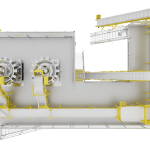

Main Components:

- Belt conveyor – reversible, controlled by sensor signal

- Belt conveyor – for temporary product accumulation

- Belt conveyor – for redirecting products to other conveyors

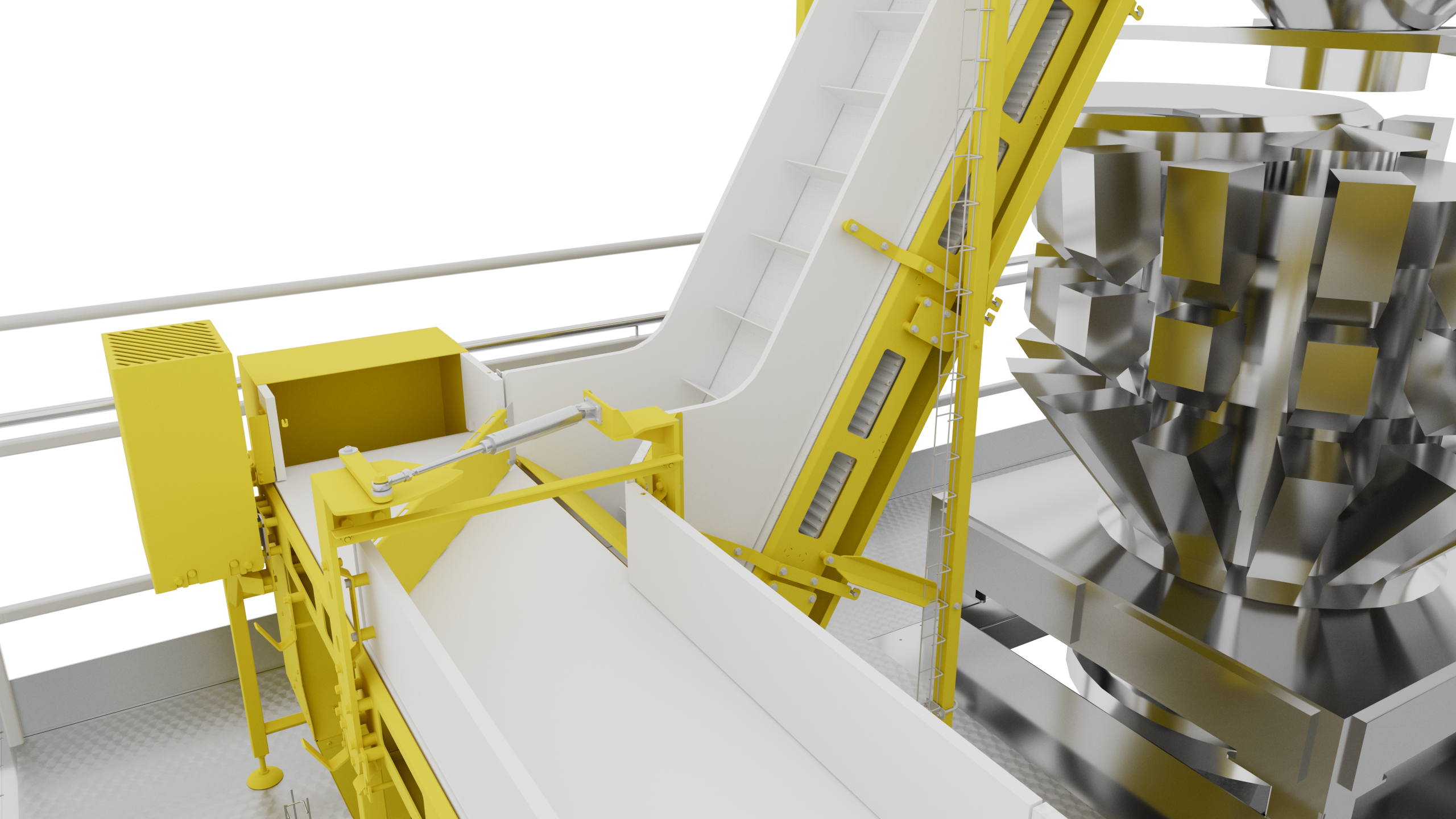

- Belt conveyor – transfers products to a vibratory conveyor

- Belt conveyor – mounted on a swivel fork with braking mechanism

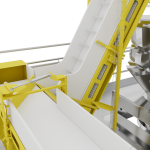

- Belt conveyor – inclined downward

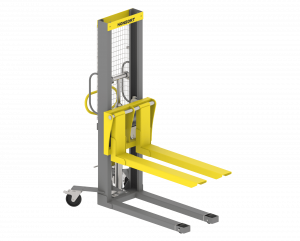

- Z-type belt conveyor – for loading products via a mobile tipping loader

- Belt conveyor – inclined downward

- Z-type belt conveyor – transfers products to another conveyor

Principle of operation

The equipment operates based on the principle of continuous conveyor transportation. Raw materials or formed products are fed to the initial section of the line, after which they pass through several stages:

- Feeding and sorting – semi-finished products are placed on the conveyor belt automatically or manually.

- Transportation and processing – products are moved to the next production stages (forming, breading, freezing, packaging).

- Quality control – visual inspection and rejection stations can be integrated.

- Transfer to packaging – ready semi-finished products are evenly fed to packaging or packing machines.

This organisation ensures high productivity, reduces waste and defects, and guarantees consistent product quality.

Advantages of the KONSORT semi-finished product line

✅High productivity — continuous product movement shortens the production cycle

✅Process automation — minimises manual labour and human error

✅Gentle handling — preserves product integrity and shape

✅Flexible configuration — allows integration of additional modules for specific production needs

✅Experienced manufacturer — KONSORT equipment operates successfully at dozens of facilities in Ukraine and abroad

How to order the KONSORT semi-finished product line

- Submit a request via our website or call us using the provided contact details.

- Get a consultation from our specialist — we will clarify all production details and your specific requirements.

- Receive a tailored solution — we will select the optimal configuration and modules for your needs.

- Agree on price and lead time — we offer the best terms directly from the manufacturer without intermediaries.

- Manufacturing and installation — we deliver, install, and launch the equipment at your facility.

Order your semi-finished product processing line in Ukraine at a competitive price from KONSORT — and get a reliable solution for automating your food production business.

Improving in the organization of production and management by 65%

Improving in the organization of production and management by 65%  Productivity increase up to 60%

Productivity increase up to 60%  Lower labour costs by 78%

Lower labour costs by 78%  Reduction in human-related risks by 40%

Reduction in human-related risks by 40% - Frozen semi-finished product production facilities

- Meat processing plants

- Packaging lines in the food industry

- Compliance with sanitary standards for the food industry

- Optimization of internal logistics within the production area

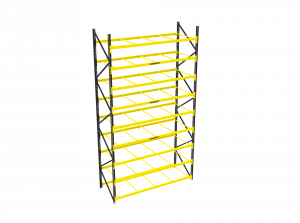

- There is possibility to complete the line with extra components if necessary

- Increased production efficiency of the facility