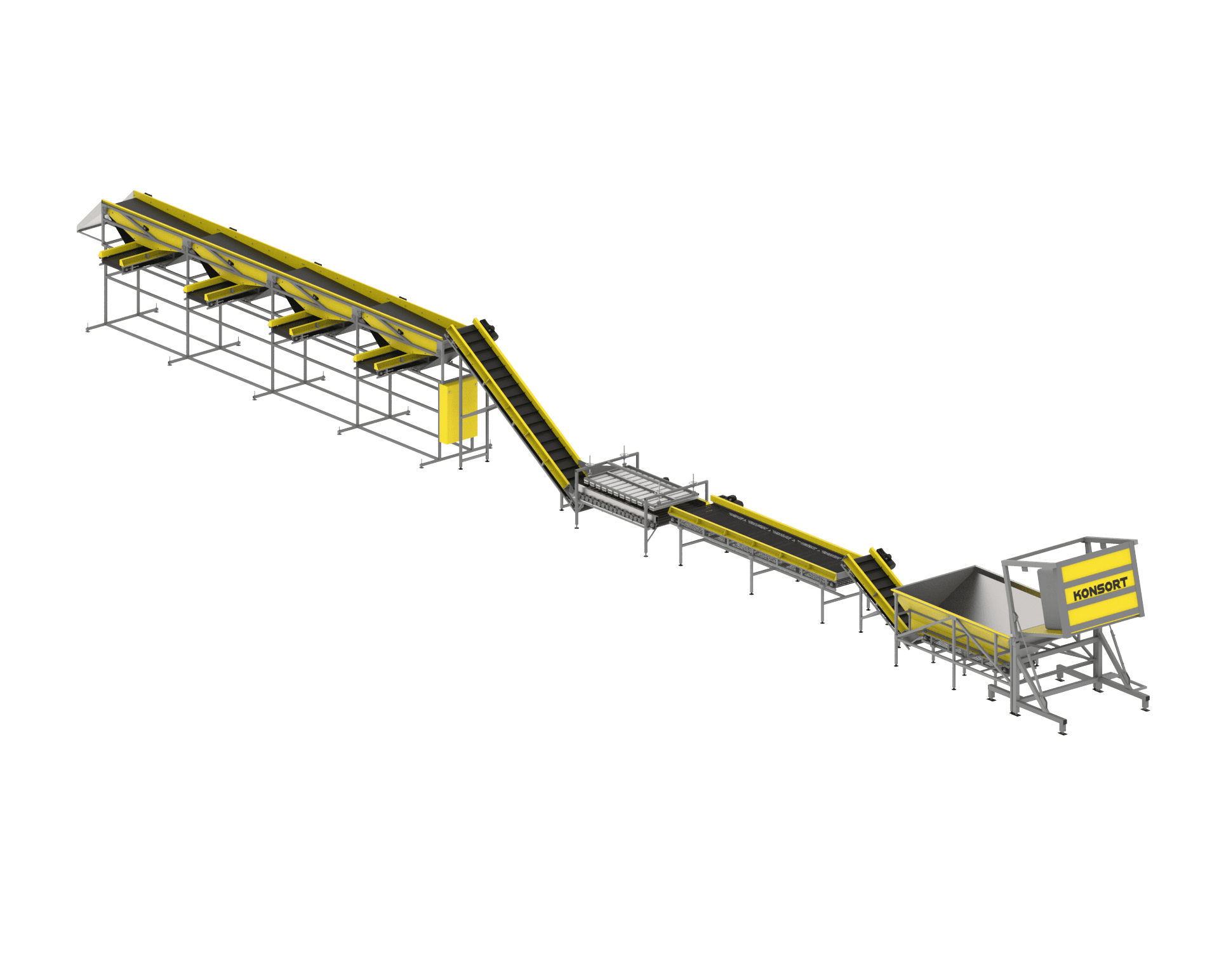

Line for garlic and onion

Order a Garlic and Onion Processing Line from the Manufacturer (Ukraine)

Description

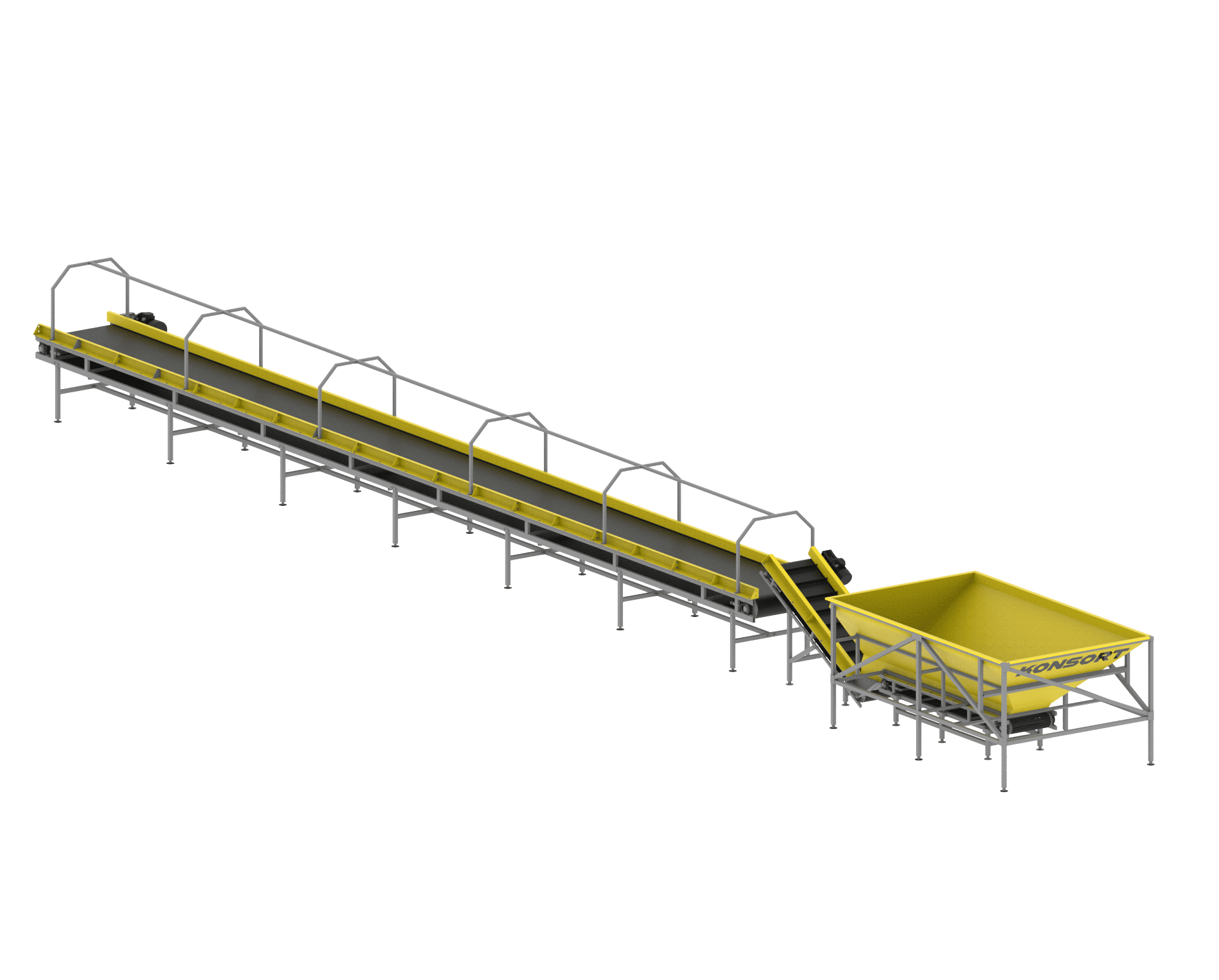

The Garlic and Onion Processing Line is a modern automated solution from the Ukrainian manufacturer KONSORT, designed to enhance the efficiency of garlic and onion processing, sorting, and preparation for further processing or packaging. This equipment is ideal for food industry enterprises, agricultural companies, and production facilities working with vegetable products.

Main components:

- container tipper

- receiving hopper

- inclined frame conveyor

- rod inspection table

- brush roller conveyor

- inclined frame conveyor

- belt grader (calibrator)

- discharge conveyor with reverse function

Staff per shift:

- sorters – up to 8 persons

- line operator – 1 person

- forklift driver or responsible container handling personnel – 1 person

Advantages:

✅ Customization – designed according to the specific needs of your production

✅ Production optimization – minimizes manual operations

✅ Adaptability – can be integrated into existing production processes

Order a modern garlic and onion processing line from KONSORT – automate your production process, increase efficiency and product quality, and reduce manual labor costs!

Improving products quality and grade up to 80%

Improving products quality and grade up to 80%  Productivity increase up to 80%

Productivity increase up to 80%  Lower labour costs up to 65%

Lower labour costs up to 65%  Reduction in human-related risks up to 30%

Reduction in human-related risks up to 30% - Agricultural enterprises and farms

- Vegetable semi-finished product manufacturers

- Food industry enterprises

- European design provides a professional and clean look

- Minimizes the need for manual operations

- Capability for integration into existing production processes

- Optimization of productivity and reduction of production costs