Problems:

- Low waste sorting efficiency: Traditional waste sorting methods are time-consuming and require a large workforce.

- High transportation and disposal costs: The need to transport waste to specialized landfills and sorting stations leads to additional expenses.

- Inefficient use of space on sites: Sorting and processing waste can be complicated without the implementation of specialized systems.

- Environmental pollution: The lack of effective sorting and processing methods can lead to ecosystem contamination.

Solution:

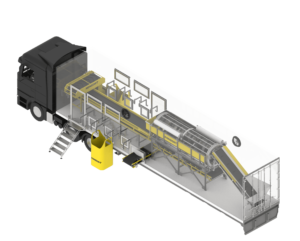

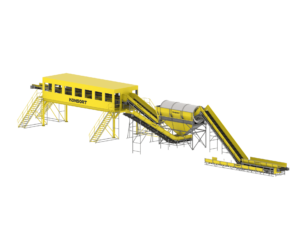

KONSORT offers mobile waste sorting lines that automate the waste sorting processes without the need for large investments in stationary installations. The use of specialized conveyor systems and technologies ensures a high level of efficiency, which is crucial for cities, towns, local communities (OTG), environmental organizations, and commercial enterprises.

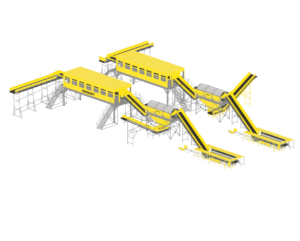

Solution Structure:

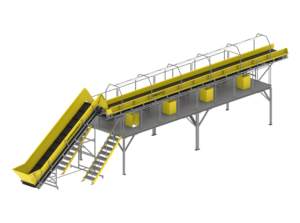

- Mobile conveyor systems:

- Belt conveyors: for transporting waste to the mobile sorting line.

- Screw conveyors: for handling heavy or large materials.

- Inclined conveyors: for feeding waste into the necessary sorting zones.

- Sorting systems:

- Magnetic separators: for extracting ferrous metals from the waste stream.

- Cyclonic separators: for processing non-ferrous metals and plastic materials.

- Vibrating screens: for sorting waste by size and further separating organic and inorganic materials.

- Pneumatic systems: for extracting lightweight materials (plastic, paper) and reducing manual labor.

Integrated Sorting Systems for Different Types of Waste: Mobile waste sorting lines allow for simultaneous work with different types of waste: plastic, paper, metal, and organic materials.

Types of Equipment:

- Belt conveyors: for transporting waste to the mobile station.

- Magnetic drums: for extracting ferrous metals from the waste stream.

- Vibrating screens: for separating materials by size.

- Pneumatic systems: for separating lightweight materials.

- Cyclonic separators: for processing non-ferrous metals.

- Mobile containers: for storing sorted materials.

Advantages of Mobile Waste Sorting Lines:

- Time savings: Automating the sorting process reduces the time required for waste processing.

- Cost reduction: Lower transportation and processing costs thanks to the mobile solution.

- Increased productivity: Mobile systems allow for faster sorting and more efficient use of resources.

- Flexibility and mobility: The ability to move the sorting line from one location to another provides convenience when working with different locations and types of waste.

- Environmental friendliness: A high level of sorting allows for increasing the amount of waste that can be recycled and reducing the amount of waste going to landfills.

Practical Application Cases:

- Cities and towns (OTG): for organizing local waste sorting and recycling programs.

- Eco-organizations: for implementing sustainable waste management solutions.

- Commercial enterprises: for sorting industrial waste at factories and plants.

- Agricultural enterprises: for sorting organic waste and its subsequent disposal.

- Recycling companies: specialized companies that recycle certain materials greatly increase recycling efficiency.

Results of Implementing a Mobile Waste Sorting Line:

- 35-80% increase in sorting productivity.

- 40-45% reduction in waste disposal costs.

- 60% increase in the amount of materials recycled.

- Reduction in the volume of waste going to landfills due to efficient sorting.

Conclusions: Implementing mobile waste sorting lines not only reduces costs but also ensures efficient waste management. This modern solution is suitable for cities, towns, local communities (OTG), eco-organizations, and commercial enterprises aiming to improve waste management and meet current environmental requirements.