Snail processing line

Order a conveyor line for snail processing directly from the manufacturer (Ukraine)

Description

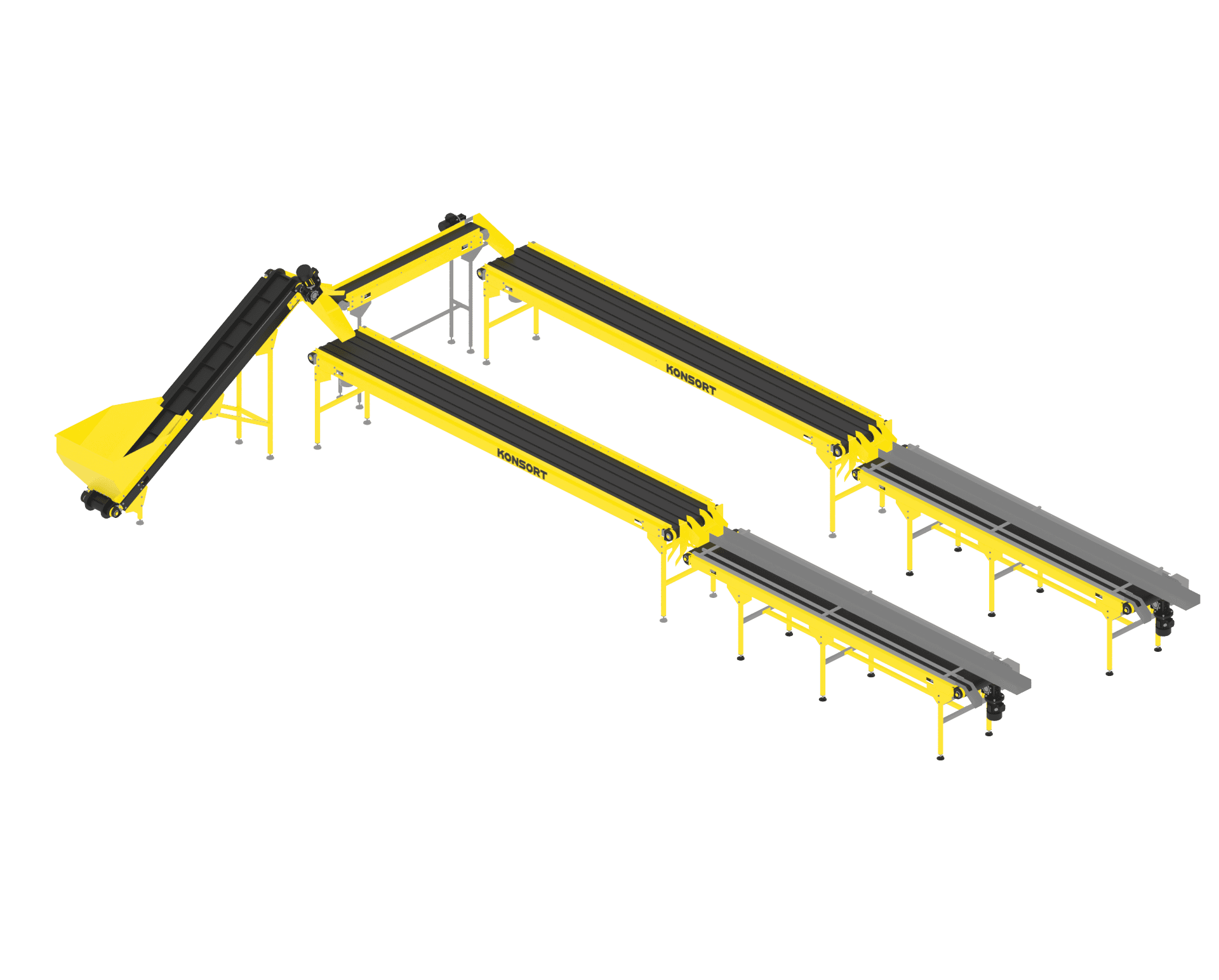

The snail processing line is a modern solution for food industry enterprises engaged in snail farming, processing, and packaging. The equipment ensures automation of processing and preparation for further transportation, sorting, and packaging. By implementing advanced technologies, the line allows optimization of production, reduction of costs, and improvement of final product quality.

Main components:

- loading conveyor

- conveyor with flow distribution

- inspection conveyor

- optional vibration sieve set

Advantages:

✅ Stainless steel construction to comply with sanitary standards

✅ Reduced risk of errors — automated processes ensure precision

✅ Robust design and long service life

✅ Integration into existing packaging and product transportation lines

Order your snail processing line from the manufacturer – automate your process and increase your business profitability!

Improving products quality and grade up to 80%

Improving products quality and grade up to 80%  Productivity increase up to 90%

Productivity increase up to 90%  Lower labour costs up to 60%

Lower labour costs up to 60%  Reduction in human-related risks by 20%

Reduction in human-related risks by 20% - Enterprises for snail farming and sales

- Food processing plants specializing in seafood processing

- Enterprises engaged in food product export

- Minimization of manual labor and stable product processing quality

- Made of food-grade stainless steel

- Compatibility with existing packaging, sorting, and product transportation lines

- Increased business efficiency