In this article we will try to explain the difference between the types of conveyors and the directions of their application.

What is a belt conveyor?

In today’s world, the belt conveyor has become the most widespread, thanks to its versatility. The equipment is used at transportation of freights loose, artificial, lump and other types. The device is a continuous conveyor belt that moves a variety of products, both packaged and in bulk. It is also used in current production for the purpose of inter-operational transportation. The principle of operation of the device is simple.

Advantages of the belt conveyor

The belt conveyor differs in practicality and unpretentiousness in service and operation. It can be used in fairly harsh conditions. For example at a temperature in the range from -40 to +130 degrees. At the same time they are suitable for transportation of various types of production: artificial, packaged, bulk. This makes it possible to use belt conveyors in almost any production.

Variety of belt conveyors

This type of conveyors is divided into several types:

Horizontal. The most common type of conveyors, which has a wide range of applications. Are used both in industrial production, and on bases, storages, warehouses. Provide transportation of bulk, artificial, packaged products. Depending on the place of application, they can be of any length.

Inclined. Today it is an indispensable equipment for the transportation of piece goods at different heights. Such as loading and unloading containers, bags, boxes, rolls, etc.

Similar conveyors with the fixed or with an adjusting angle of inclination are made. The working surface of the inclined belt conveyor is a conveyor belt that can move on rollers or a plane. The drive drum sets the movement of this belt by means of a photoreducer with the desired power. This type of equipment is used both in industrial production and in logistics centers, warehouses for moving goods at different levels.

Indirect. Z and L-shaped conveyors have a special design, which may include several bends, which ensures easy and simple movement of loads in an inclined position at different levels and heights.

Z and L-shaped conveyors have the following advantages: -reduced cost of equipment due to versatility (horizontal and inclined conveyors in “one bottle”); – due to the compactness of the equipment saves working space; -loads can move at an angle of 60 degrees. To move subsequent loads can be used Z and L conveyors: -bags, boxes, boxes, containers of insignificant weight; – granulated and small freights (for example, gravel, garbage, sawdust); – freights of loose property (sand, construction mixes, rubble). If it is necessary to transport loose freight, the tape with corrugated boards is used not to let the content to wake up).

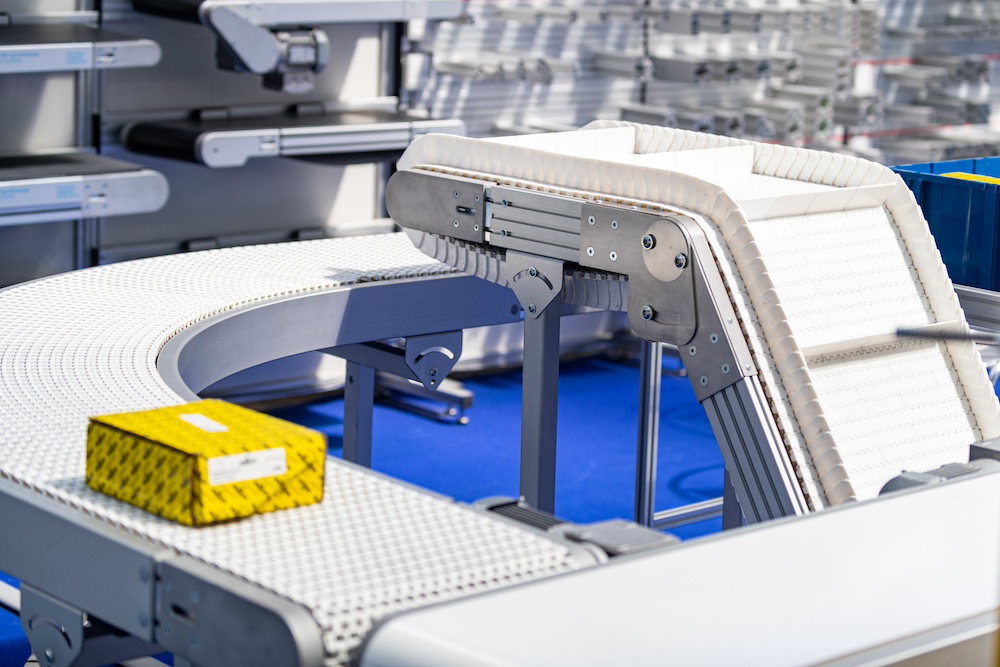

Swivels. The rotary belt conveyor provides movement of freights in different directions. With the use of equipment of this type, it is possible to create conveyors with a complex trajectory. They allow you to bend corners, change the direction of the transported cargo, as well as move the cargo from one line to another. Provides rotation at any angle up to 180 degrees. Indispensable in cases where it is necessary to ensure a minimum radius of rotation of the conveyor line or due to the properties of the product it is impossible to use conveyors with a modular belt.

According to the degree of mobility, belt conveyors can also be: stationary, mobile, lifting, rotary.

Why buy a conveyor from us?

KONSORT ™ has been manufacturing and supplying belt conveyors to the Ukrainian market for over 13 years. The quality of the tape from the Italian manufacturer “Kiorino” meets international standards.

The professional approach of the sales department managers and the experience of the design department provide an opportunity to develop the conveyor individually according to the customer’s wishes.

Production takes 15 days. Installation of equipment, training of customer staff and warranty service throughout Ukraine, are the benefits that will help the customer to assess cooperation with “KONSORT” .