Roller conveyors at the enterprise: everything you need to know about roller conveyors

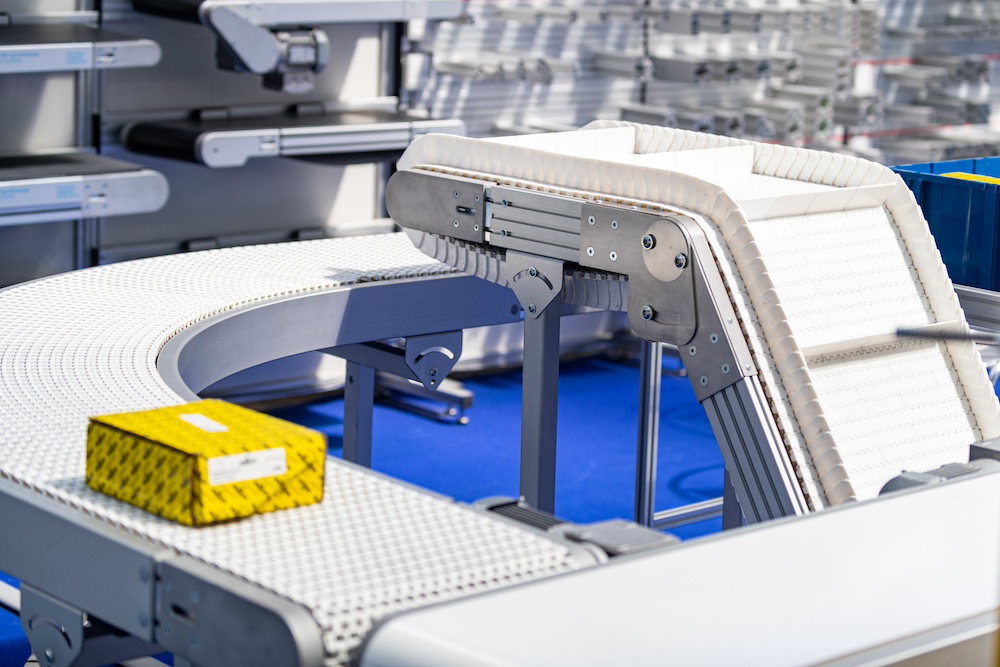

Roller conveyors are an important component of modern industrial transport systems, ensuring the efficient transfer of goods over short and medium distances. They are widely used in various industries, in particular in manufacturing, logistics and warehousing. In this article we will look at the types of roller conveyors, their manufacture, advantages and features, and how they work.

Types of roller conveyors

Roller conveyors come in different types, each meeting specific needs and conditions of use. Here are some of the most common types of roller conveyors:

Gravity Roller Conveyors These conveyors use natural gravity to move loads. They are usually located on a slight slope and the load moves under its own weight.

Driven Roller Conveyors: In these conveyors, the rollers are driven by a driving mechanism such as a motor or gearbox. This allows you to accurately control the speed and direction of movement of the load.

Straight Roller Conveyors: Simple and standard conveyors consisting of rollers arranged in series. They are ideal for moving loads in a straight line over short distances.

Rotary roller conveyors These conveyors have the ability to rotate around their axis. They allow you to change the direction of cargo transfer, which is useful in warehouse conditions.

Sliding Roller Conveyors This type of conveyor consists of sections that can be extended or retracted. This allows you to adjust the length of the conveyor depending on the volume of work or the size of the load.

Stationary Roller Conveyors These conveyors are fixed in one place and are used to transfer load from one point to another within a limited area, such as a warehouse or manufacturing facility.

Traveling Roller Conveyors These conveyors have wheels or rollers that allow them to move easily around the work area. They are convenient for use in situations where you need to transfer cargo between different places.

Each of these types of roller conveyors has its own unique characteristics that allow them to perform effectively in different conditions and applications.

Production and features of roller tables

Roller conveyors consist of a metal frame and rollers that are spaced apart from each other. Casters can be made of different materials, such as metal, plastic or rubber, depending on the characteristics of the load being carried.

One of the advantages of roller conveyors is their ease of maintenance and repair. The rollers can be easily replaced when broken or worn. In addition, roller conveyors can be easily adapted to different operating conditions and specific customer requirements.

The use of roller tables in the areas

Roller conveyors are a critical component in various industries, manufacturing and logistics. Their versatility and adaptability make them an important tool for optimizing cargo transportation. Overall, roller conveyors are a necessary element for many businesses and help improve freight transport, increase productivity and reduce risks in the work environment.

Roller conveyors are widely used in various industries and fields of activity due to their efficiency and versatility. Here are some of the usual areas and places where roller tables are used:

Manufacturing: Roller conveyors are used to transport products between different workstations, increasing efficiency and speeding up the production process.

Roller conveyors help in unloading and picking orders in warehouses. They can be used to move goods quickly and accurately in warehouses.

Logistics Centers: In logistics facilities, roller conveyors are used to transport goods between different processing stations and to pick and assemble goods before shipping.

Distribution Roller conveyors help to efficiently unload vehicles such as vans or containers and transfer goods to storage or processing areas.

Roller conveyor production lines can be integrated into production lines to automatically move products between production and processing stages.

Automotive industry: In automobile manufacturing, roller conveyors are used to transport bodies, parts, and components between different areas of the plant.

Exchange of goods in stores: In large stores and shopping centers, roller tables can be used to quickly move goods from the warehouse to the shelves.

Hotel and Restaurant: Roller conveyors can be used in hotels and restaurants to transport dishes, food or luggage between different areas.

Food Manufacturing and Packaging: In the food industry, roller tables can be used to move products between processing stations and packaging lines.

Agriculture: roller tables

https://konsort.com.ua/productcat/conveyors-and-conveyors/