Types of conveyors

Conveyors are an integral part of modern industry and logistics, used to automate the movement of materials and products in manufacturing plants and warehouses. There are many different types and types of conveyors, each of which has its own unique features and applications. In this article, we will consider different types of conveyors, their purpose, manufacturing features and advantages.

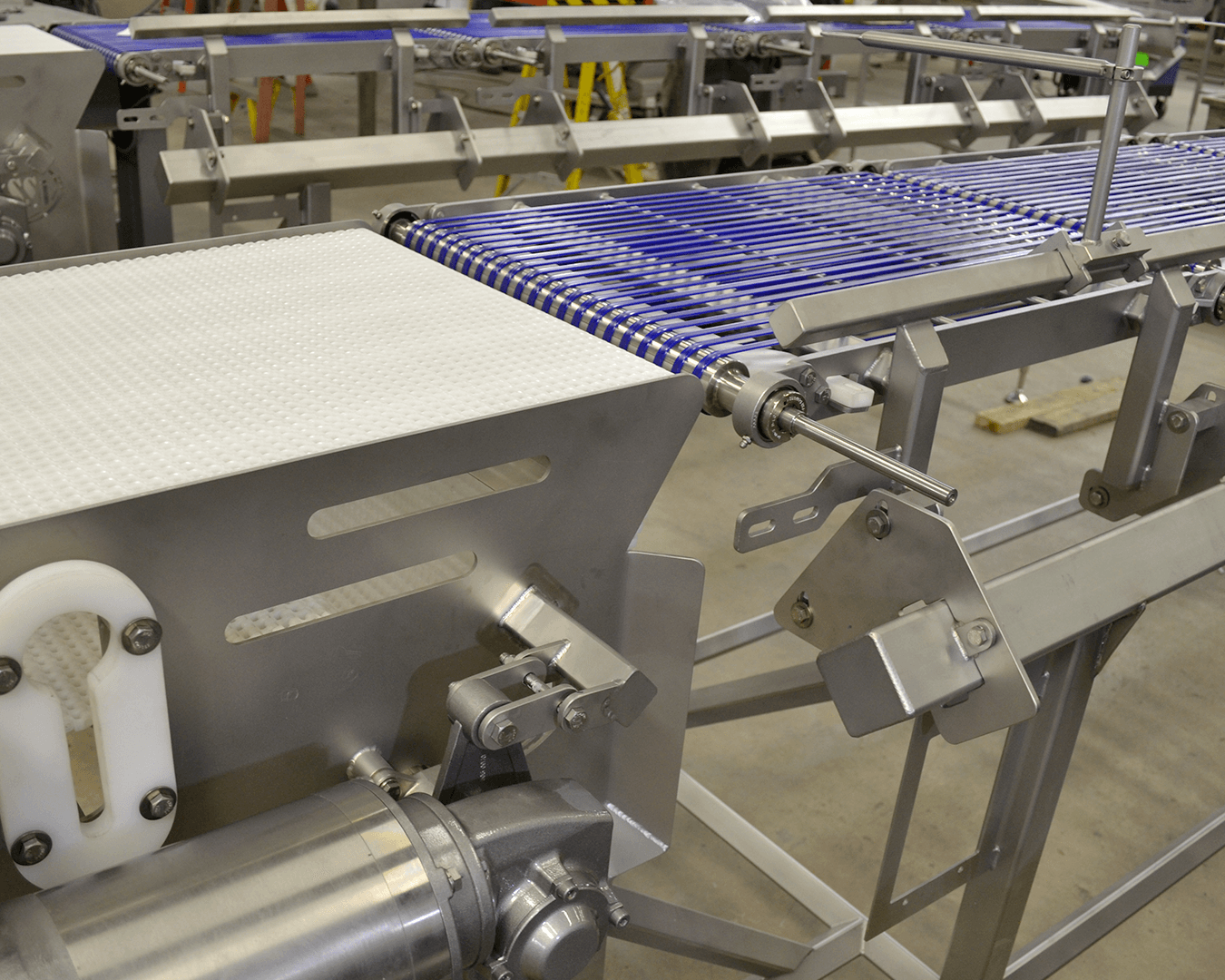

1. Belt conveyors

Purpose: Belt conveyors are one of the most common types of conveyors used for horizontal movement of goods or materials.

Features:

They consist of a long belt that moves around two drums.

They are used for transporting light and heavy materials, including packaged goods, bulk materials, as well as agricultural products.

Can be equipped with various sorting and loading mechanisms.

Advantages:

Great productivity.

Easy management and maintenance.

Suitable for various types of cargo.

2. Telescopic conveyors

Purpose: Telescopic conveyors allow goods to be unloaded from vehicles such as trucks or containers.

Features:

Can go beyond buildings and warehouses to load goods directly into a vehicle.

Able to expand and contract depending on requirements.

Often used in warehouses and ports for fast and efficient unloading.

Advantages:

Increase the unloading speed.

Minimize the risk of employee injuries.

They save space in the warehouse.

3. Bucket conveyors

Purpose: Bucket conveyors are used to move large volumes of loose and heavy materials, such as sand, gravel, cement.

Features:

Have buckets attached to a belt or chain that grab the materials and lift them to a higher destination.

They are used on construction sites, in quarries and during ore extraction.

Advantages:

High productivity when working with heavy materials.

Reducing the need for manual intervention.

Effective use of labor force.

4. Elevator conveyors

Purpose: Elevator conveyors are used for vertical movement of bulk materials such as grain, sugar, concrete and other bulk goods.

Features:

They have large vertical pipes in which materials are moved.

They are often used in agriculture and the food industry to transport loose raw materials.

Advantages:

Preservation of the integrity of bulk goods during movement.

Effective use of space in production.

Automated management and control system.

5. Tubular conveyors

Purpose: Tubular conveyors are used to transport materials in a vacuum or in an environment with increased pressure.

Features:

They have closed tubes that ensure reliable transport of materials even in clogged conditions.

They are used in the chemical industry to transport aggressive substances.

Advantages:

Ensure the safety of transportation of hazardous materials.

Reduce losses due to leakage or contamination of materials.

6. Chain conveyors

Purpose: Chain conveyors are used to transport heavy and small objects, such as automotive components, steel blanks.

Features:

These conveyors have chains that move around two drums and carry goods or materials along the conveyor.

They are often used in the automotive and metallurgical industries.

Advantages:

Can carry heavy loads.

They have a long service life.

7. Screw conveyors

Purpose: Screw conveyors are used to move loose and viscous materials, such as flour, cement, salt, clay.

Features:

These conveyors have a screw rotating element that moves the materials along the auger.

They are used in the food and chemical industry, as well as in agriculture.

Advantages:

High efficiency when working with viscous and loose materials.

Can be positioned at an angle for ease of loading and unloading.

8. Scraper conveyors

Purpose: Scraper conveyors are used to transport coarse and aggressive materials, such as slag, coal, sulfur.

Features:

Have plates or chains with attached scrapers that move the materials.

Used in heavy industry such as mining and metallurgy.

Advantages:

High strength and long service life.

Designed to work in aggressive environments.

9. Plate conveyors

Purpose: Plate conveyors are used to transport heavy and bulky objects, such as steel sheets, plywood sheets.

Features:

They have metal plates that move and carry goods.

They are used in metallurgy, woodworking industry and other areas.

Advantages:

Can carry large and heavy loads.

The possibility of installing various additional devices for processing goods.

10. Lifting conveyors

Purpose: Elevating conveyors are used to move goods to a great height, which are then lowered.

Features:

Have a system of chains or belts that raise the goods to a height and lower them down.

They are used in warehouses and factories to maximize the use of available space.

Advantages:

Ensure efficient use of vertical space.

Ability to control speed and direction of movement.

11. Roller conveyors

Purpose: Roller conveyors are used to move goods over long distances, especially when it is necessary to easily change the direction of movement.

Features:

They have rollers on which goods are rolled.

They are used in various industries and logistics.

Advantages:

Easy change of direction of movement of goods.

High reliability and long service life.

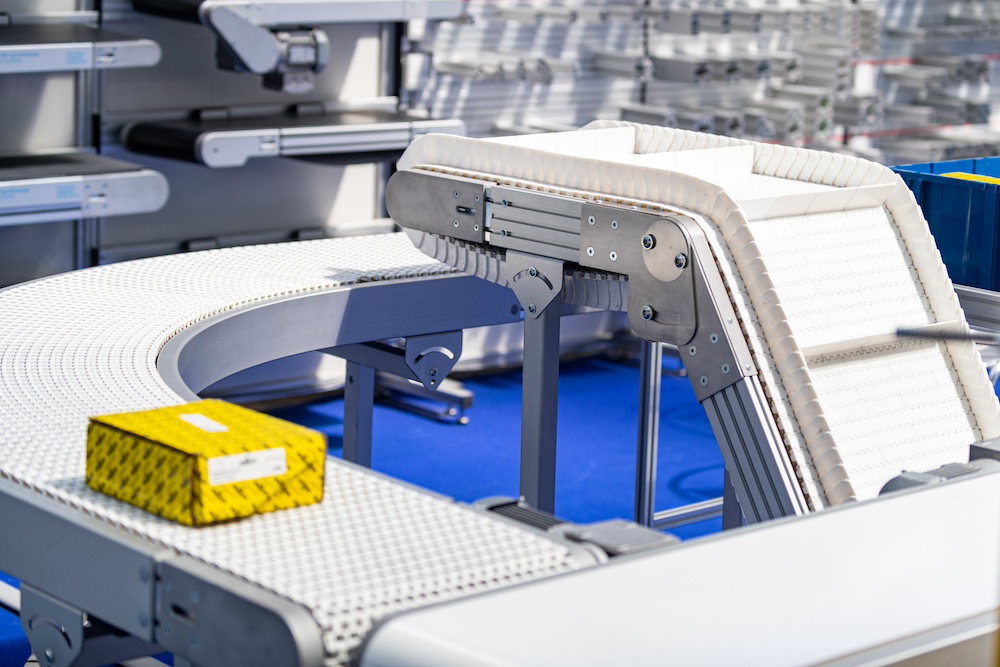

12. Rotary conveyors

Purpose: Rotary conveyors are used to change the direction of movement of goods at an angle.

Features:

They have special mechanisms that allow you to change the angle of the direction of movement.

They are used in warehouses and factories where it is necessary to change the direction of movement of goods.

Advantages:

They provide efficient transport of goods in narrow spaces.

Possibility of automated control.

Areas of use of conveyors

Automobile industry

Conveyors are used for the automated movement of auto parts during the production of cars.

Logistics and distribution

In warehouses and transport hubs, conveyors are used for quick and efficient sorting and distribution of goods.

Food Industry

Conveyors help in automating the processes of packaging, sorting and transporting food products.

Heavy industry

In heavy industry, conveyors are used to move large and heavy objects such as steel beams or concrete blocks.

Mining and extraction

In these industries, conveyors are used to transport ore, coal, minerals and other raw materials.

Functions and tasks of conveyors

Conveyors can perform various functions and tasks at enterprises:

Transportation of materials

The main function of conveyors is to transfer materials from one place to another without the need for manual intervention.

Sorting

Conveyors can automatically sort products by size, shape, weight or other parameters.

Packaging

They help package goods in accordance with established standards and requirements.

Loading and unloading

Conveyors allow automated loading and unloading of goods from vehicles.

Amen

Conveyors play an important role in modern industry and logistics, facilitating the transportation of various types of materials and goods. Each type of conveyor has its own unique characteristics and applications, making them essential elements for various industries. Choosing the right type of conveyor depends on the specific needs and tasks of your enterprise. You can learn more about different types of conveyors and view equipment models by going to the “Products” section on our website.