Mass production is the driving force of the industrial world, providing the ability to produce large volumes of products in a short period of time. To achieve maximum production efficiency, various types of production organization are used, each of which has its own advantages and limitations.

With the help of conveyor systems and equipment for production automation, maximum productivity is achieved. In this article, we will look at the different types of serial production and the importance of the participation of conveyors and automated equipment in this process, and give examples for a better understanding.

Line Production: Organization of the Process from Start to Finish

Linear manufacturing is a manufacturing organization strategy in which the entire manufacturing process is broken down into sequential steps that are performed at different stations on an assembly line or production line. This approach allows you to optimize time and resources, reduce costs and increase productivity. Let’s take a closer look at the features of linear production and give examples of its use:

Features of linear production:

Sequence of steps: In linear manufacturing, the entire production process is divided into successive steps, each of which is performed at a corresponding station or work point.

Stability and uniformity: Each station concentrates on performing one specific task or operation, which ensures stability and uniformity of the production process.

Increased productivity: Linear production allows for the optimization of the use of equipment and workers, resulting in increased overall productivity.

Examples of using linear production:

Ford Motor Company: Ford uses linear manufacturing in its factories to make cars. The entire production process is divided into successive stages — from assembly of the body to installation of parts and final assembly. This approach allows Ford to ensure high quality and production efficiency.

Coca-Cola: In the production of beverages, the Coca-Cola Company also uses linear production. The process of bottling and packaging drinks is divided into successive stages on the conveyor, which allows to ensure the stability and quality of products.

Samsung Electronics: In the production of electronics, Samsung also applies linear manufacturing. Each stage of production, from the manufacture of microcircuits to the assembly of devices, is divided into sequential operations, which allows the company to efficiently produce a wide range of electronic goods.

Line production remains one of the most common and effective methods of organizing production in the world of industry. From cars to beverages, this approach allows businesses to deliver consistent, high-quality products.

Cellular production: an innovative approach to production organization

Cellular manufacturing is a production organization strategy based on the division of the production process into small autonomous groups, or “cells”, that specialize in the production of specific products or components. This approach allows enterprises to remain flexible and quickly respond to changes in market demand. Let’s take a closer look at the features of cellular production and examples of its use:

Features of cellular production:

Autonomy of cells: Each cell performs production operations independently of other groups, which allows enterprises to quickly respond to changes and provides a high level of production flexibility.

Specialization: Each cell specializes in the production of a specific product or component, which allows to reduce the time for reconfiguration of equipment and increases production efficiency.

Effective management: The management of cellular production is usually carried out at the local level, which facilitates quick decision-making and increases the efficiency of the management of the production process.

Examples of the use of cellular production:

Toyota Production System (TPS): Toyota uses cellular manufacturing in its factories to produce cars. Each cell at TPS specializes in the production of a specific component or family of vehicles, allowing the company to ensure high quality and production flexibility.

Samsung Electronics: Samsung uses cellular manufacturing in its factories to produce electronic components such as chips and sensors. Each cell specializes in the manufacture of a certain type of component, which allows the company to ensure high quality and speed of production.

Nestle: In the food industry, Nestle also uses cellular manufacturing to produce a wide range of products. Each production cell specializes in the production of a certain type of product, which allows the company to quickly respond to changes in market demand and ensure the high quality of its products.

Cellular manufacturing opens up new opportunities for enterprises in flexible and efficient production of products, allowing them to be competitive in today’s market environment.

Flexible manufacturing: adaptability in the industrial world

Flexible production is a production organization strategy that supports an enterprise’s ability to quickly adapt to changes in demand, technology, and market conditions. This approach provides the ability to quickly reconfigure production lines and processes to produce different products without significant retooling costs. Let’s take a closer look at the features of flexible production and give examples of its use:

Features of flexible production:

Rapid reconfiguration: Flexible manufacturing involves the use of technologies and equipment that can be quickly reconfigured to produce different types of products.

Equipment modularity: Equipment in flexible manufacturing typically has a modular structure that allows modules to be added or removed with ease depending on production needs.

Flexibility in planning: Production planning in a flexible approach is usually based on demand forecasting and the ability to respond quickly to changes in market conditions.

Examples of the use of flexible production:

Flextronics Factory: Flextronics is a leading service provider in the field of electronic products. They use flexible manufacturing to manufacture a wide range of electronic devices, from smartphones to medical equipment. Thanks to the flexibility of its lines, Flextronics can quickly adapt to changes in demand and technology.

Zara Company: Zara is a well-known fashion clothing manufacturer and retailer. Their production strategy is based on flexible production, which allows them to quickly respond to new fashion trends and changes in consumer demand. With the help of flexible production processes, Zara can quickly produce new collections and adapt its products to the needs of the market.

Tesla car company: Tesla uses flexible manufacturing to make its electric cars. Their production lines can be quickly reconfigured to produce different car models and take into account the individual wishes of customers.

Flexible manufacturing is critical for businesses in today’s competitive environment. The ability to quickly adapt to changes and efficiently produce a variety of products allows companies to remain competitive and respond to market demands.

The role of conveyor systems and automation equipment in modern production

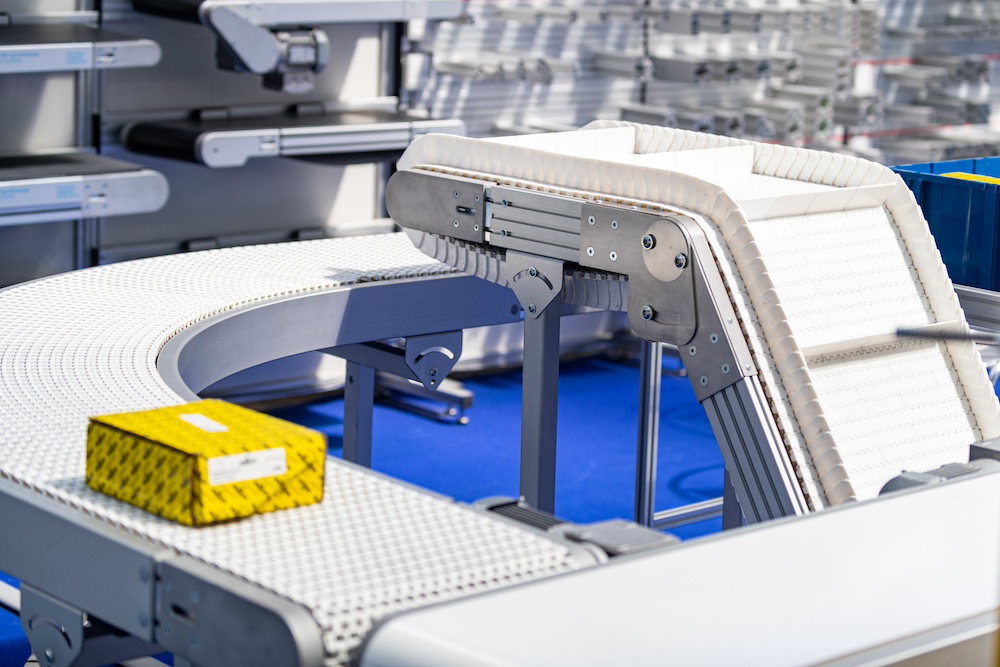

Conveyor systems and automation equipment play a key role in maintaining an efficient and productive production process. Their use allows you to reduce labor costs, increase production speed, ensure quality stability and reduce the risk of errors. Let’s consider in more detail the role of conveyor systems and equipment for automation, and also give examples of their use:

1. Automation of the material movement process:

Conveyor systems allow you to automate the movement of materials and products along the production line. This greatly increases productivity and efficiency, as workers do not need to spend time manually moving materials.

Use case: A BMW car factory uses conveyor systems to move car bodies along the production line, allowing them to increase the speed of car assembly and reduce labor costs.

2. Robotic manufacturing systems:

Robotic manufacturing systems enable the automation of complex manufacturing operations such as welding, painting, assembly, etc. They ensure high accuracy and stability of the process, and also reduce the risk of errors.

Use case: Tesla uses robotic systems to weld the bodies of its electric cars. This allows them to ensure high quality welding and increases production productivity.

3. Visualization and monitoring systems:

Modern conveyor systems and automation equipment are often equipped with visualization and monitoring systems that allow operators to monitor and control the production process in real time.

Example of use: In the production of food products, Nestle uses monitoring and visualization systems to control the quality and safety of products at various stages of production.

Conveyor systems and automation equipment are an integral part of modern manufacturing, helping businesses increase efficiency, reduce costs and ensure high product quality. Their use is a key factor in ensuring competitiveness in the market.

So, summarizing the above, we can come to the conclusion that conveyor systems play an important role in modernization, automation and productivity improvement of modern production of various products. their use allows enterprises to achieve significant advantages in many aspects of the production process. The final conclusion is as follows:

1. Modernization and automation: The introduction of conveyor systems into production processes is a key stage in the modernization of production. They allow you to automate routine operations, reducing labor costs and increasing the accuracy and speed of production.

2. Productivity improvement: Conveyor systems allow you to optimize production processes, ensuring consistent and efficient movement of materials and products. This leads to increased productivity and reduced time required to manufacture products.

3. Quality assurance: The use of conveyor systems improves the quality of products through a stable and controlled production process. This allows enterprises to ensure high product quality and meet consumer requirements.

In general, the importance of conveyors in modernizing and increasing the productivity of modern production is extremely great. Their use allows enterprises to ensure efficiency, economy and high quality of products, which are critical factors in today’s competitive world.

The KONSORT company is a leader in the field of production of conveyor systems, which has many years of experience and a successful track record in the development and implementation of projects. Over the past 15 years, KONSORT has produced more than 4,000 projects from various industries, providing its customers with state-of-the-art solutions for optimizing production processes.

Thanks to the accumulated experience and professional approach, the KONSORT company is ready to provide its customers not only with advanced conveyor systems, but also with free advice from experts. Our specialists will be happy to help you with the development and implementation of the optimal solution that meets your needs and the requirements of your business.

Get a free consultation from KONSORT experts for a reliable partnership in solving your production task and achieving your business success. Call: +38 (067) 116-50-25