Do you need Ukrainian walnuts in Europe and Asia?

Once again, Ukraine broke the record of the previous 2018 in the export of nuts. But revenue from the sale of walnuts in Europe fell. The decline in export earnings, according to analysts, is due to a general decline in prices for this type of nut in the European Union and Asia, which is the largest buyer of Ukrainian products. Walnut offered by Ukrainians exporters, unfortunately, are mostly non-varietal. To get closer to the quality of premium quality walnuts, such as the world leader in US exports, it is necessary to pay attention to processing and sorting.

Equipment from the company “KONSORT” ™ Will help to process and 100% sell walnut.

Processing equipment is a reliable guarantor of product realization!

A comprehensive solution for nut growers will help even a beginner to navigate the process of walnuts from the garden to readiness for sale.

- Wood shaker. This equipment minimizes harvesting time

Cable length: standard 10 m; other length on request.

Cable diameter: 8 mm; other diameter depending on the type of tree.

Working height: trees up to 6500 mm (Telescopic bar extends 1500 mm – 4500 mm)

Weight: 54 kg

Drive – Gear motor, requires connection to a generator or mains.

- Roll for collecting nuts

Length – 38 cm, height – 24 cm, width – 24 cm. Weight – 1.5 kg. Material: hot steel. Gray. The handle – the holder is not included in the package.

- Wash the separator around the ovary

Calibrator type – Rotary;

Productivity – 1000 kg \ h.

First, the sink is a receiving hopper, which evenly feeds the nut into the washing drum to further clean the nut from the green skin. Cleaning is carried out by means of the established system of a nozzle through which water supply is carried out.

After cleaning, the green skin goes into a separate special hole, which is located under the drum, and the cleaned nut goes further to the conveyor through a special tray.

Material of construction is steel. Dyeing – powder baking.

Connection 220V / 380V

- Dryer for nuts

Power consumption – 10 kW;

Power of 3 shades total 9 kW;

The volume of the bunker is 1 cubic meter. meter;

Rated voltage – 380 V / 220 V;

Overall dimensions:

– length – 3500 mm;

– width – 1050 mm;

– height – 1150 mm;

The dryer consists of a frame, a covering, hatches for unloading of nuts, heaters, the fan and electricity. Switching on: the fan is started, after which the heaters are switched on depending on the required temperature.

- Calibrator for walnuts in shell

Calibrator type – Rotary;

Productivity – 1000 kg \ h;

Initially, the calibrator is a hopper for unsorted nuts, which evenly feeds the nut into the drum of the calibrator for further distribution into fractions from 26 mm to 32 mm and more;

Material of construction is steel

- Nutcracker

Productivity: up to 250 kg / h.

Percentage of whole kernel: up to 70%.

Engine power (power consumption) 0.75 kW.

Material: steel.

Color: according to the customer.

Dimensions: 60 * 120 * 50.

Weight: 65 kg.

Walnut caliber adjustment function.

Possible equipment for 220 V / 380 V. Warranty: 1 year.

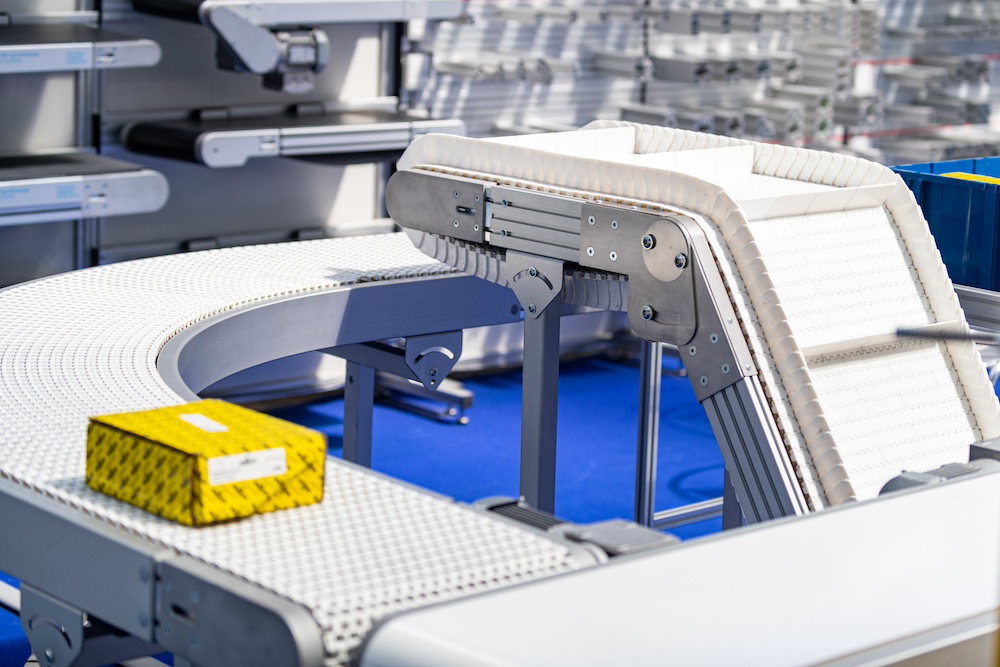

- Inspection table

Inspection table: horizontal, frame, stationary

Type of tape: PVC white, 2 mm thick.

Dimensions: 4000mm * 700mm * 800mm

Flow separators are made of profile pipe 15.

The speed of the belt is adjustable.

Reduction motor with a capacity of 0.55 kW, with a frequency converter.

Metal manufacturing: structural steel.

Productivity is 1000 kg per hour.

- Vibrating sieve for peeled nuts and sorting nuts into fractions 1/2, 1/4, 1/8 and crumb

Vibrating sieve type – lattice.

The vibrating sieve is completed with three sieves with the overall dimensions of 1250 mm × 2500 mm.

The sizes of an opening on sieves are 6 mm, 16 mm, 20 mm.

200 kg hopper.

Output trays for 3 fractions are placed at the end of the vibrating sieve.

The output of the 4 fraction is placed under the body of the vibrating sieve.

The vibrating sieve is completed with the vibrator of 0,55 kW made in Italy.

Power supply 380V.

Weight of installation no more than 350 kg.

Productivity is 1000 kg / h.

- Aspiration system

Application: It is installed to the output trays of the vibrating sieve to remove dust, small debris from walnuts.

Engine power, W 2200

The diameter of the outlet, mm 305

Inlet diameter, mm 150 Number of inlets, 3 x 100

Faster air flow, m3 / min 65.09

Diameter of a bag, mm 500

Height of a filter bag, mm 850

Height of a garbage collector, mm 1100

Volume of a bag, m3 0.4

Dimensions L x W x H, mm 1450 x 800 x 2250

Net / gross weight, kg 53/58

Package size, mm 1170 x 560 x 570

- Vibrating sieve with aspiration

We have considered the most cost-effective option using structural steel, which is painted with a powder baking chamber, which significantly increases the service life of the equipment by slowing down the process of metal corrosion.

Turnkey solutions – lines for sorting and processing nuts

Nutcrackers, processors and exporters need equipment – KONSORT ™ has a wide selection of equipment. But the manufacturer “KONSORT” ™ also has a solution – “turnkey”. This is a complex for processing walnuts.

The company can manufacture equipment in different versions at the request of the customer. Either this is structural steel / galvanized sieves, or all stainless steel equipment. Various options of a complete set and modification are also possible.

KONSORT ™ is primarily customer-oriented and is a profitable, reliable and highly qualified manufacturer. The rich potential of the team is concentrated on the implementation of individual customer needs. Thanks to the experience of the team and the study of global trends in the production of equipment, the company offers customers the latest developments and achievements, which are embodied in real products “turnkey”.