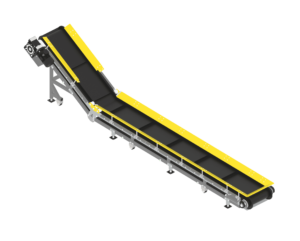

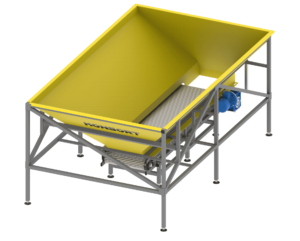

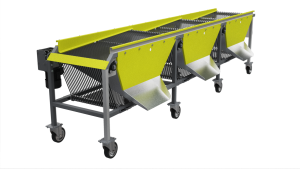

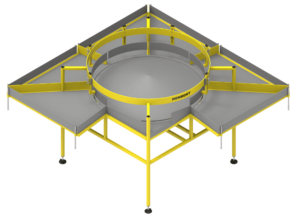

01. Automation of harvesting

Automation of the harvesting process with the help of specialized conveyor systems allows to significantly increase productivity and reduce crop losses. The use of moving belts and roller conveyors to move the collected products minimizes the need for manual labor and speeds up the collection process.