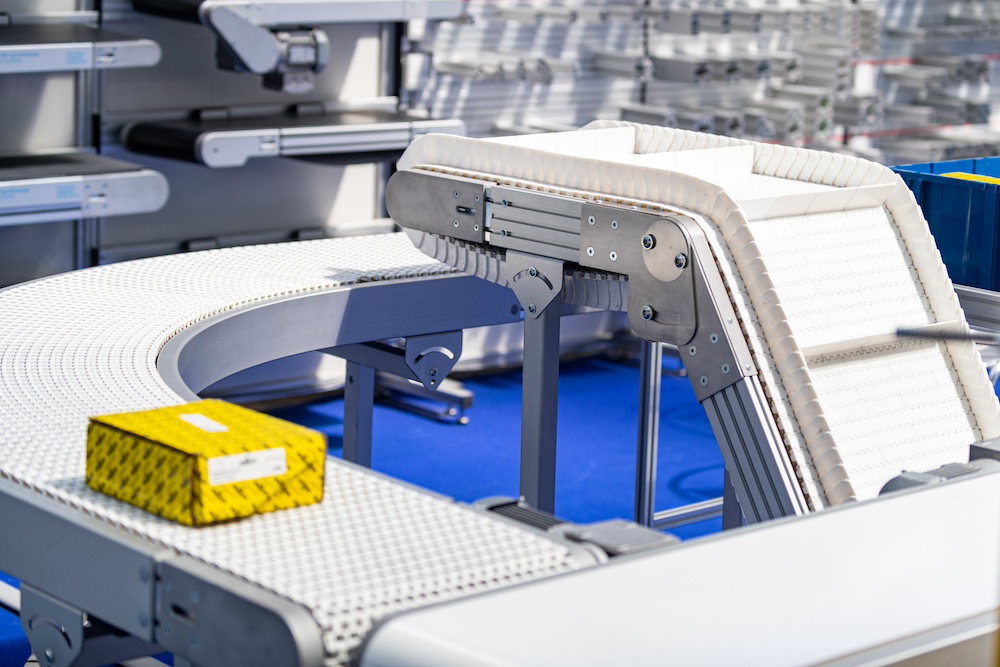

Conveyor: a universal tool for automation in production and in the warehouse.

Introduction

Conveyor systems are one of the most versatile tools in the field of automation, which are used in various areas of business, in particular in production and warehouse logistics. These systems have become an integral part of process modernization, ensuring speed, accuracy and efficiency in the movement of materials and goods. Here are some reasons why the conveyor is considered the most efficient equipment in any manufacturing or logistics enterprise:

1. Automation of production processes

Conveyors of production lines are a key component in production automation. They allow efficient and continuous movement of raw materials, semi-finished products and finished products along production lines. This helps to increase productivity, reduce production time and avoid human errors.

2. Warehouse logistics

In the warehouse industry, conveyor systems are used to optimize the movement of goods in the warehouse. They help in sorting goods, providing convenient access for preparing orders and speeding up the unloading of cargo. This makes the warehouse management process more efficient and economical.

3. Flexibility and scalability

One of the benefits of pipelines is their flexibility and scalability. Systems can be adapted to different types of production or warehouse needs. Adding or changing conveyors is easy, allowing companies to quickly adapt to changes in production or logistics processes.

4. Reduction of costs and errors

The use of conveyor systems helps reduce labor costs and improve process accuracy. Human errors in the manual movement of materials or goods can be minimized, and automated systems operate continuously and reliably.

5. Energy efficiency and environmental friendliness

Modern conveyor systems are increasingly becoming energy efficient and environmentally friendly. The use of the latest technologies and materials allows to reduce energy consumption and emissions into the atmosphere, which makes them a choice for sustainable and environmentally responsible enterprises.

Buy turnkey automation equipment

There are a number of companies in Ukraine that specialize in the production and supply of conveyor equipment. Many enterprises are looking for opportunities to buy turnkey production equipment, which means the system is completely ready for use. This ensures an effective launch of the production process without additional difficulties. For 17 years, the KONSORT company has been specializing in mechanical engineering in various industries, manufacturing turnkey conveyor systems.

Thanks to technological progress, modern automation equipment and conveyor lines can be integrated into a single control system, which simplifies the production management process. Automated assembly lines not only increase production efficiency, but also reduce labor and resource costs. KONSORT has produced more than 4,500 automation projects (an average of 300 projects per year), so the company has considerable experience in designing, manufacturing and installing equipment according to client requests.

Conveyor systems in Ukraine

Conveyor systems in Ukraine are becoming a key element for businesses seeking to increase productivity and optimize production processes. From production to logistics, they play a critical role in increasing the competitiveness of enterprises. With the high popularity of conveyor systems and the availability of equipment for production in Ukraine, businesses get a chance to effectively implement modern integrated and automated conveyor systems from a Ukrainian manufacturer. Here are some examples where conveyor systems play an important role in production and logistics processes:

1. Production and Heavy Industry:

Transportation of Raw Materials: Conveyor systems are used to move large volumes of raw materials from the point of entry to the workplaces.

Assembly and Production Lines: Conveyors are used to move products along an assembly line, simplifying the assembly process.

2. Light and Food Industry:

Packaging and Sorting: Conveyor systems automate the processes of packaging, sorting and labeling goods on production lines.

Food Processing: In the food industry, conveyors are used to transport and process products, optimizing production processes.

3. Automotive and Transport Industry:

Auto Parts Manufacturing: Conveyors help automate auto parts manufacturing lines, from body parts to electronics.

Logistics and Warehousing: In the transportation industry, conveyors are used for automated sorting and transportation of goods in warehouses.

4. Pharmaceutical Industry:

Drug Manufacturing and Packaging: Conveyor systems are used to transport pharmaceutical products from production lines to the packaging area.

Sorting and Marking: In the pharmaceutical industry, conveyors are involved in the sorting and marking of product packaging.

5. Forestry and Paper Industry:

Wood processing: Conveyor systems are used to transport logs and wood in various stages of production.

Paper Production: In the paper industry, conveyors help in automating the processes of paper production and its further processing.

Conclusion

Conveyor systems are a universal tool for production and warehouse automation. They not only speed up and optimize work processes, but also help increase productivity and improve overall business efficiency. Technological advances in this industry continue to provide new opportunities for businesses seeking to be competitive in today’s business environment.