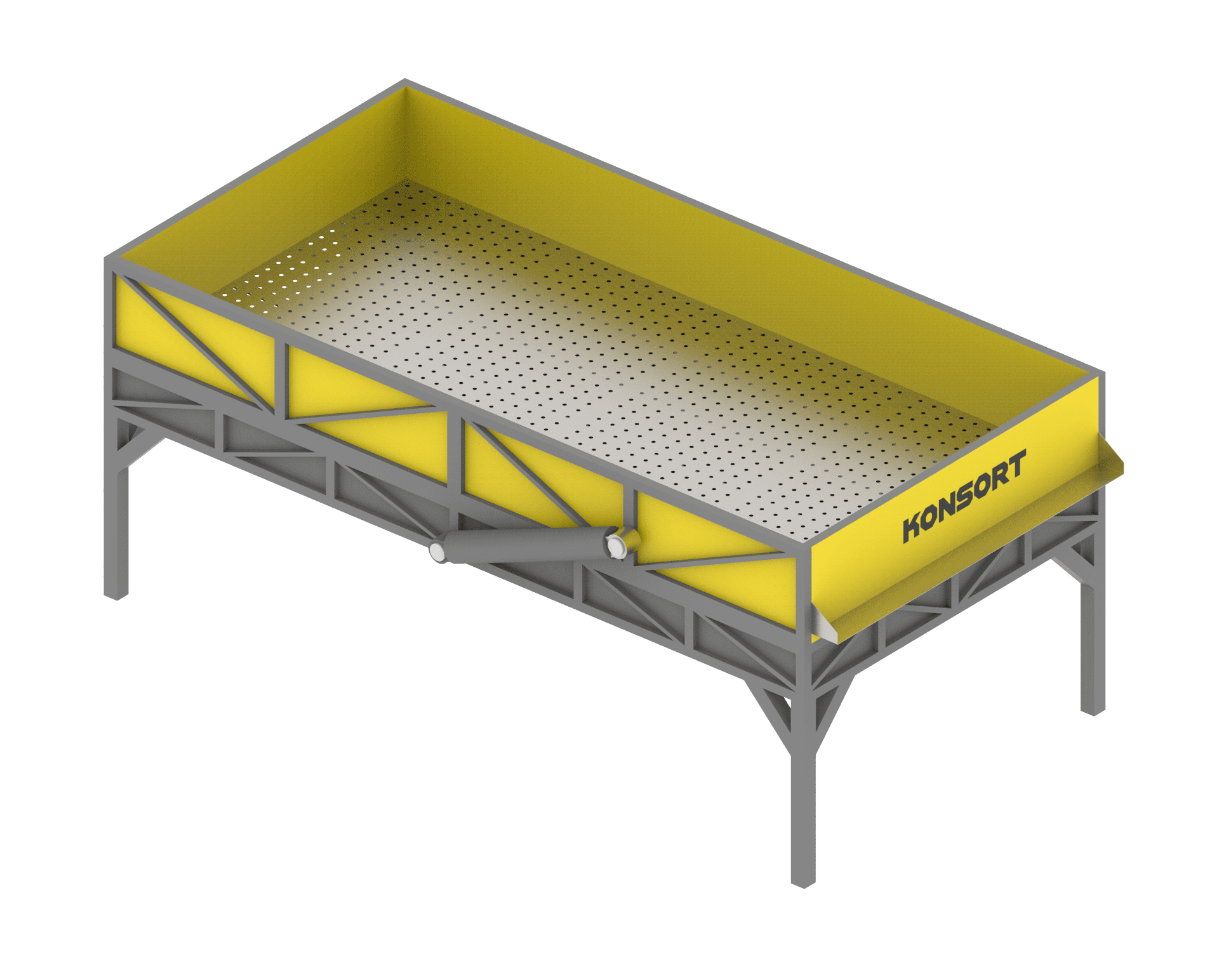

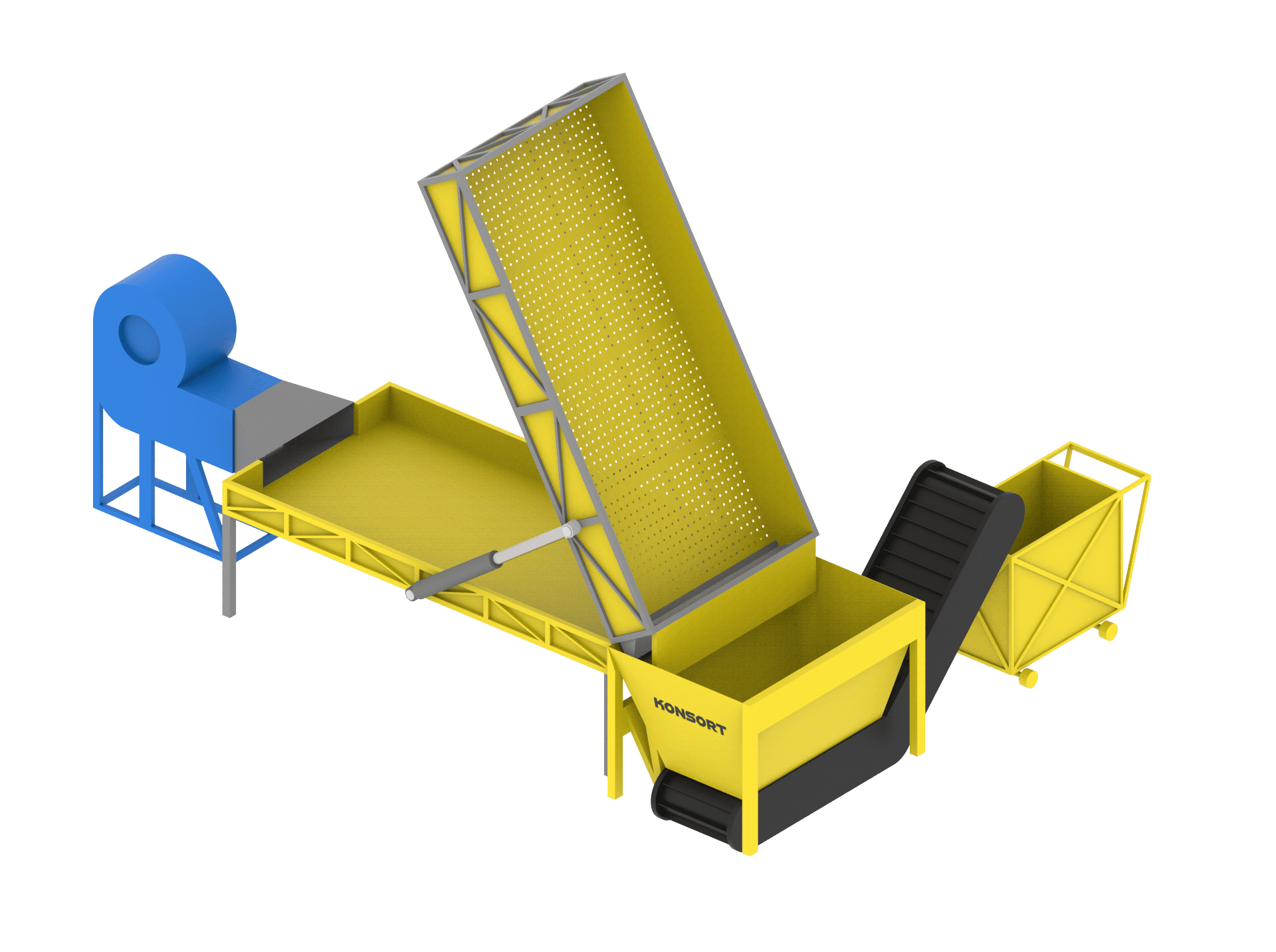

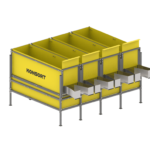

Drying chamber for nuts

This equipment is used to dry the product for further sorting. Nuts are placed in a dryer with hot air supplied by fans. In such dryers the whole process takes 20-48 hours. Temperature and air circulation power are the factors that contribute to the artificial drying. Drying chamber frame is made of structural steel. In places of contact between nuts and metal the equipment is made of food grade stainless steel.

Technical characteristics:

Overall dimensions

2 000 * 1 000 mm

Heater power

12 kW

Motor reducer

1.1 kW, Neri Motori, Italy

Blowing temperature

55-62 ° С

The equipment can be designed according to individual parameters necessary for the customer

Economic advantage:

Reducing product waste

Reducing product waste  Productivity increase up to 70 %

Productivity increase up to 70 %  Workforce optimization up to 30%

Workforce optimization up to 30%  Reduction in human-related risks

Reduction in human-related risks

Spheres of usage:

- Enterprises specialized in nuts processing and sorting

Benefits and options:

- European design

- Process automation

- Preservation of product taste

(UA) Про нас говорять

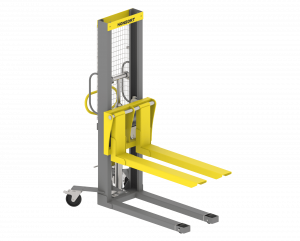

With these products are often ordered