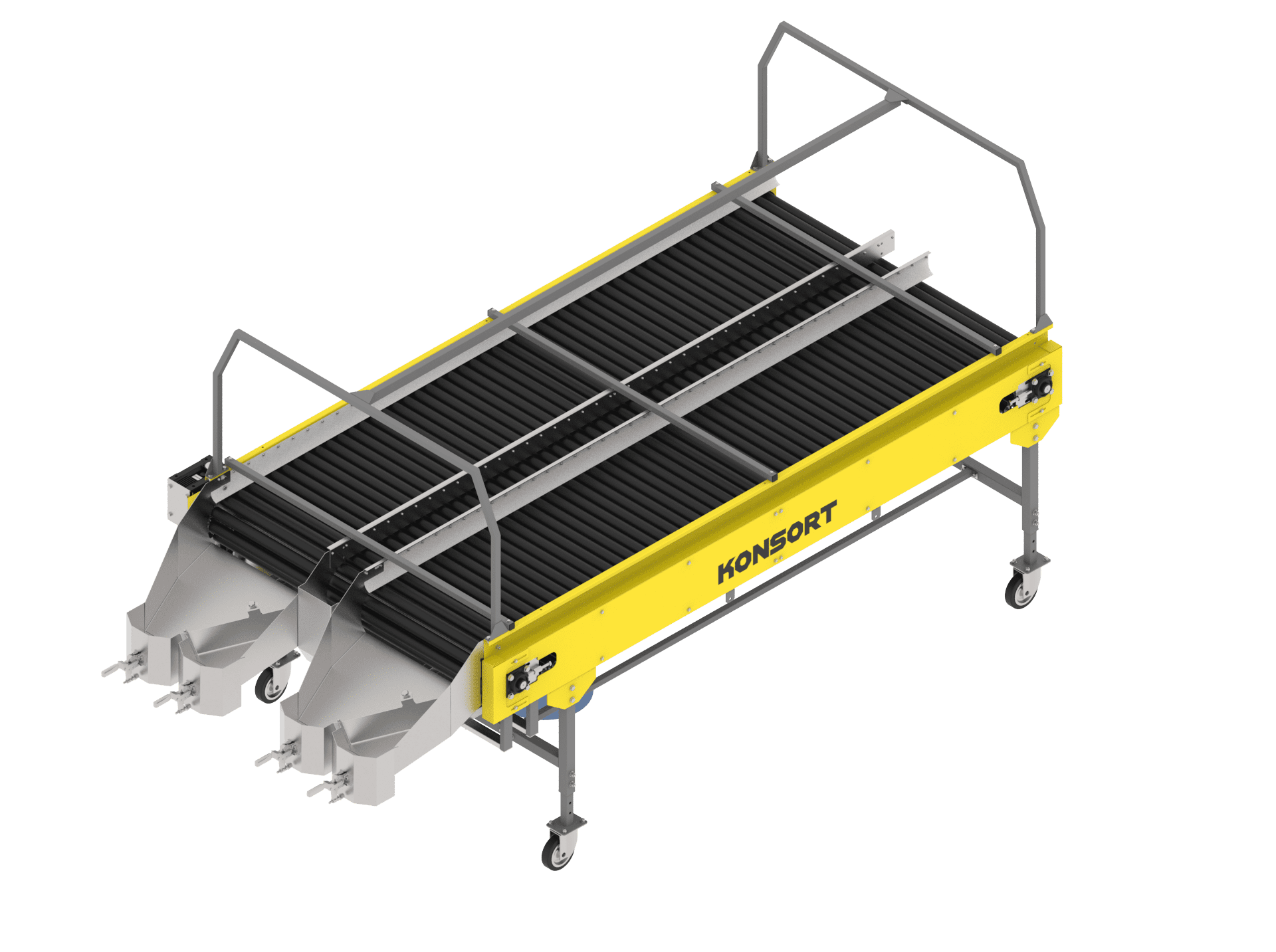

Roller inspection table

Roller inspection table – an efficient solution for quality control and product sorting

The roller inspection table by Ukrainian manufacturer KONSORT is modern professional equipment designed for visual inspection, sorting, and manual removal of defective products. It is widely used in the food and processing industry, on farms, in logistics centers, and production facilities.

This equipment is ideal for quality control and sorting of raw materials such as berries, fruits, nuts, and other food products. Thanks to its simple and reliable design, the table ensures operator convenience and stable performance.

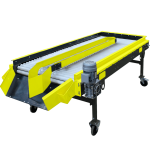

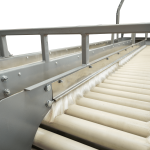

Operating principle of the roller inspection table

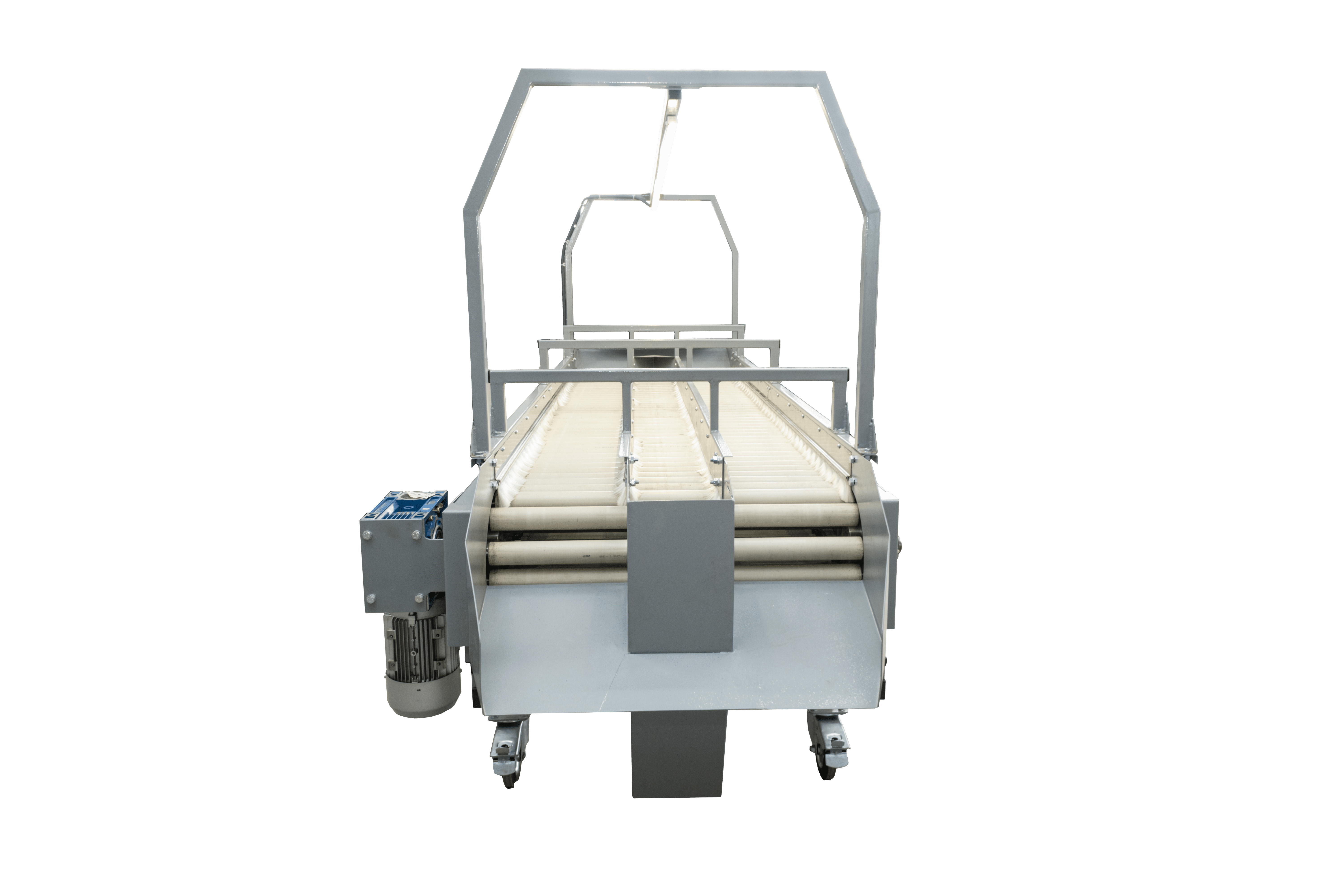

The table operates by moving products along a roller surface, which ensures smooth and even product movement and provides operators with easy access for inspection.

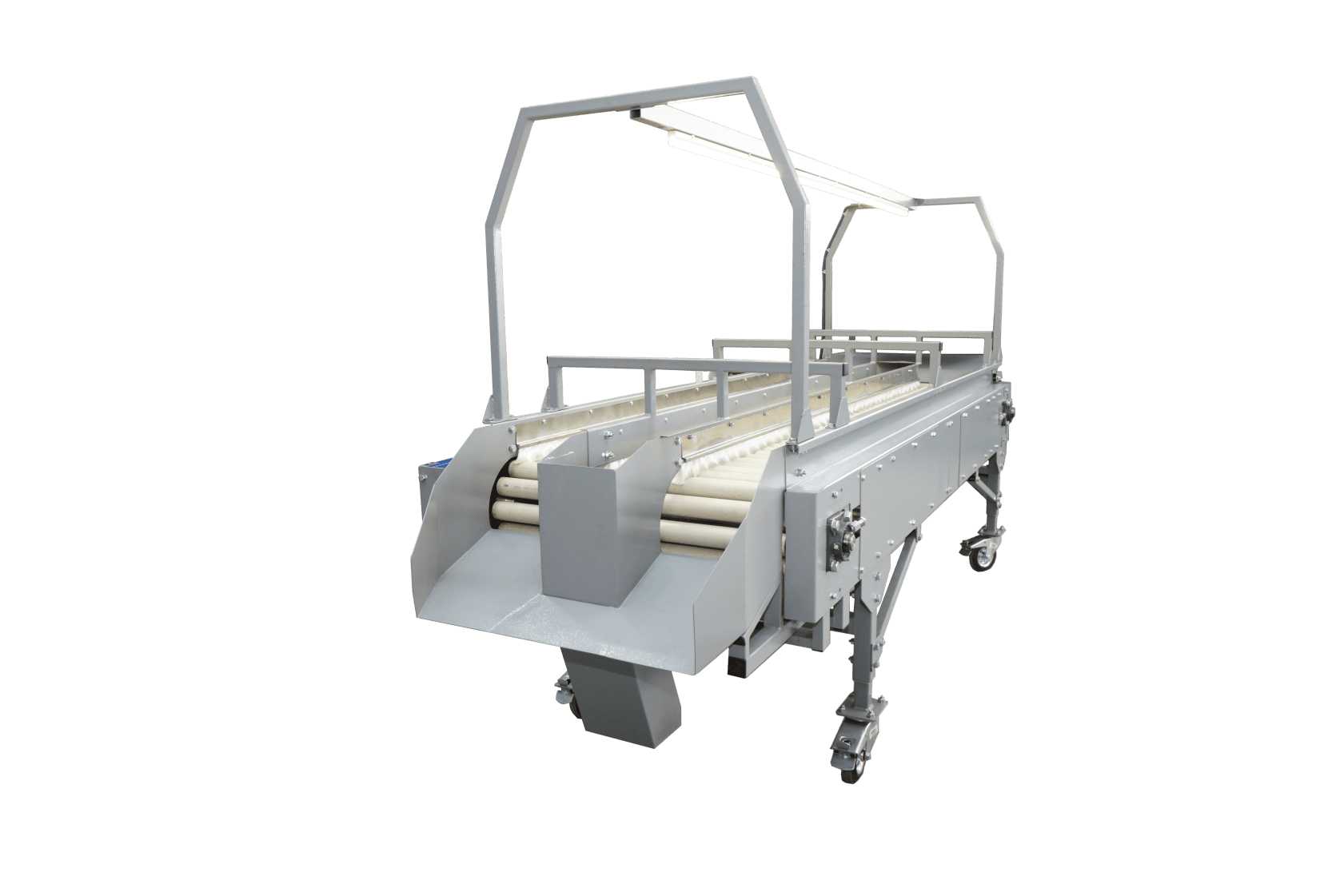

- Product Feeding – raw material is fed onto the roller section from the previous production stage

- Visual Inspection – operators visually check the condition of each unit of the product

- Manual Sorting – defective, damaged, or non-standard items are removed from the surface

- Transfer to the Next Stage – quality products continue along the line for further processing (washing, drying, packaging, etc.)

This approach allows defective raw materials to be removed at the early stages of processing, significantly improving the quality of the final product.

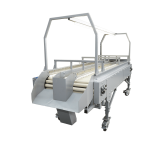

Advantages of the KONSORT roller inspection table

✅ High sorting efficiency – enables quick and accurate selection of quality products

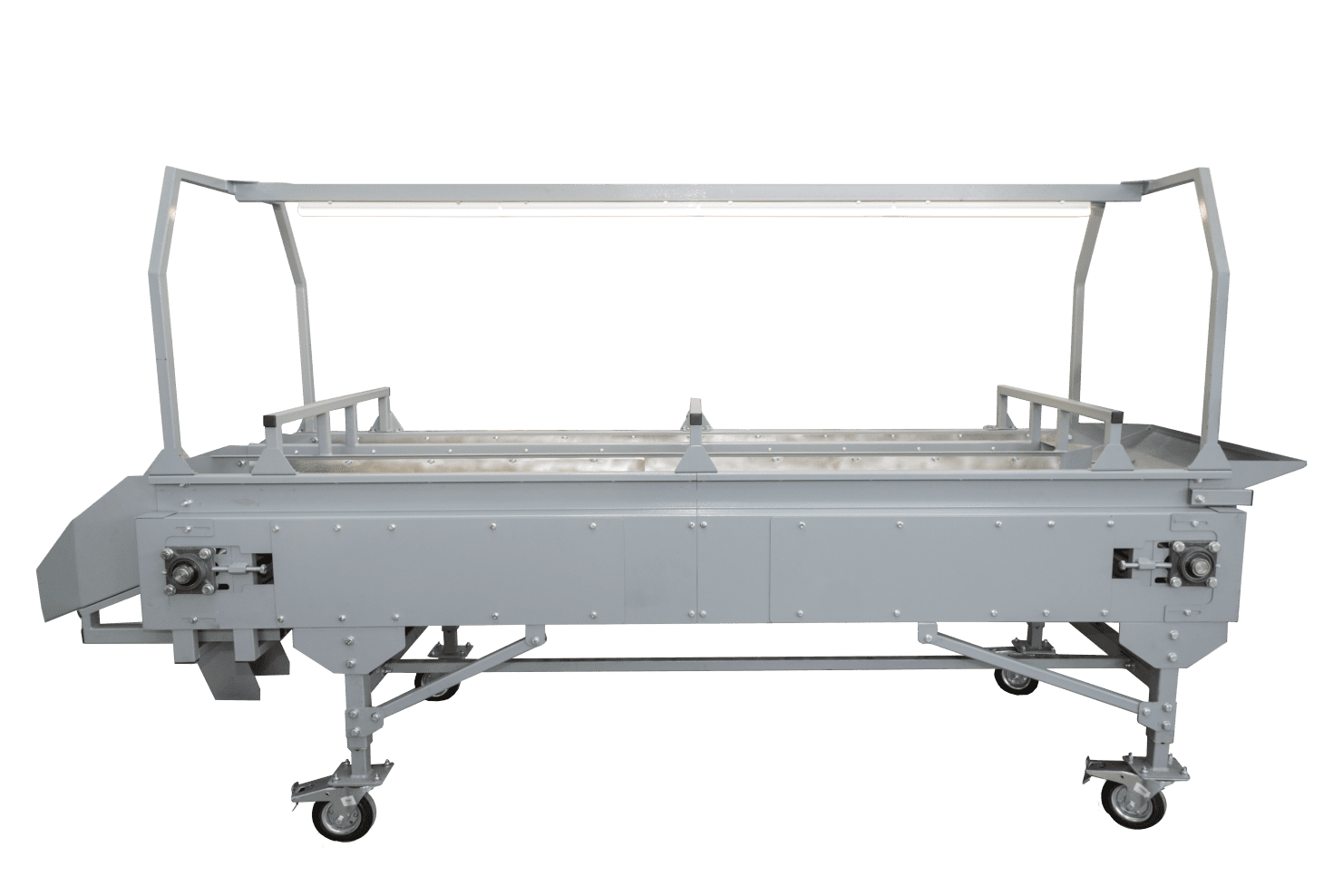

✅ Operator-friendly design – ergonomic structure and optimal working height for comfort

✅ Easy integration – can be incorporated into any production or packaging line

✅ Reliability and durability – manufactured from high-quality, wear-resistant materials

✅ Low maintenance – minimal time and resource requirements for servicing

✅ Custom manufacturing – dimensions and design tailored to specific production needs

Why buy a roller inspection table from KONSORT

KONSORT is a Ukrainian manufacturer specializing in industrial equipment for production automation. We offer:

- Direct manufacturing without intermediaries – best price from the manufacturer

- Quality assurance and after-sales service

- Custom-built solutions tailored to your production needs

- Proven experience in supplying equipment across Ukraine and internationally

How to order a roller inspection table

- Submit a request on our website or contact us by phone

- Agree on technical specifications and delivery terms

- Receive your equipment with delivery and installation options

Order now and boost your production efficiency with the KONSORT roller inspection table!

Improving products quality and grade

Improving products quality and grade  Productivity increase up to 90%

Productivity increase up to 90%  Lower labour costs

Lower labour costs  Reduction in human-related risks

Reduction in human-related risks - For quality control and sorting of raw materials — berries, fruits, nuts, vegetables, and other agricultural products

- For automation of production processes in the food, processing, and agricultural industries

- For manual removal of defective products without damaging the remaining raw material

- For use in farms, logistics centers, warehouses, and production facilities

- European design provides a professional look

- Certified European components

- The equipment is designed in accordance with all the rules and regulations put forward to the food industry equipment

- There is possibility of modification according to individual parameters