Garlic crushing equipment

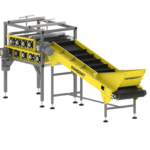

The garlic clove separating machine by KONSORT is a reliable, high-performance piece of equipment designed for the mechanical separation of garlic bulbs into individual cloves.

Purpose and advantages of the garlic separating machine

This garlic processing machine is specifically developed for enterprises seeking to optimize manual labor and improve production efficiency. The equipment automates the separation process, significantly reducing manual handling and accelerating the processing of large volumes of garlic.

Key advantages:

✅ High throughput — up to several hundred kilograms per hour

✅ Durable construction made of food-grade stainless steel (AISI 304)

✅ Minimal clove damage

✅ Easy to clean and maintain

✅ Low energy consumption

How does the garlic clove separating machine work?

Garlic bulbs are loaded into the transporter’s hopper, from where the product is evenly fed into the crushing section. The separation into cloves is carried out using two pressing conveyors. The gap between them, as well as the feed speed, can be adjusted depending on the raw material type. This mechanism ensures the integrity of the cloves while minimizing damage during processing.

A profitable investment in your production line

By investing in modern equipment, you benefit from:

-

Reduced labor costs

-

Increased processing speed and product quality

-

Compliance with sanitary regulations

-

Reliable operation under heavy workloads

Why buy the garlic separating machine in Ukraine directly from KONSORT?

-

Own manufacturing — you buy directly from the producer

-

Guaranteed quality — modern technologies and certified materials

-

Competitive pricing — affordable without compromising quality

-

Fast delivery across Ukraine

-

Professional service and support

Improving the quality of product processing, avoiding waste

Improving the quality of product processing, avoiding waste  Productivity increase up to 70 %

Productivity increase up to 70 %  Workforce optimization up to 30%

Workforce optimization up to 30%  Reduction in human-related risks

Reduction in human-related risks - Agricultural enterprises

- Enterprises specialized in pre-sale product preparation

- Wholesale warehouses and depots

- Enterprises specialized in food preservation and freezing

- European design and quality

- Productivity process automation, faster results

- Easy to use and operate

- Preservation of product qualities