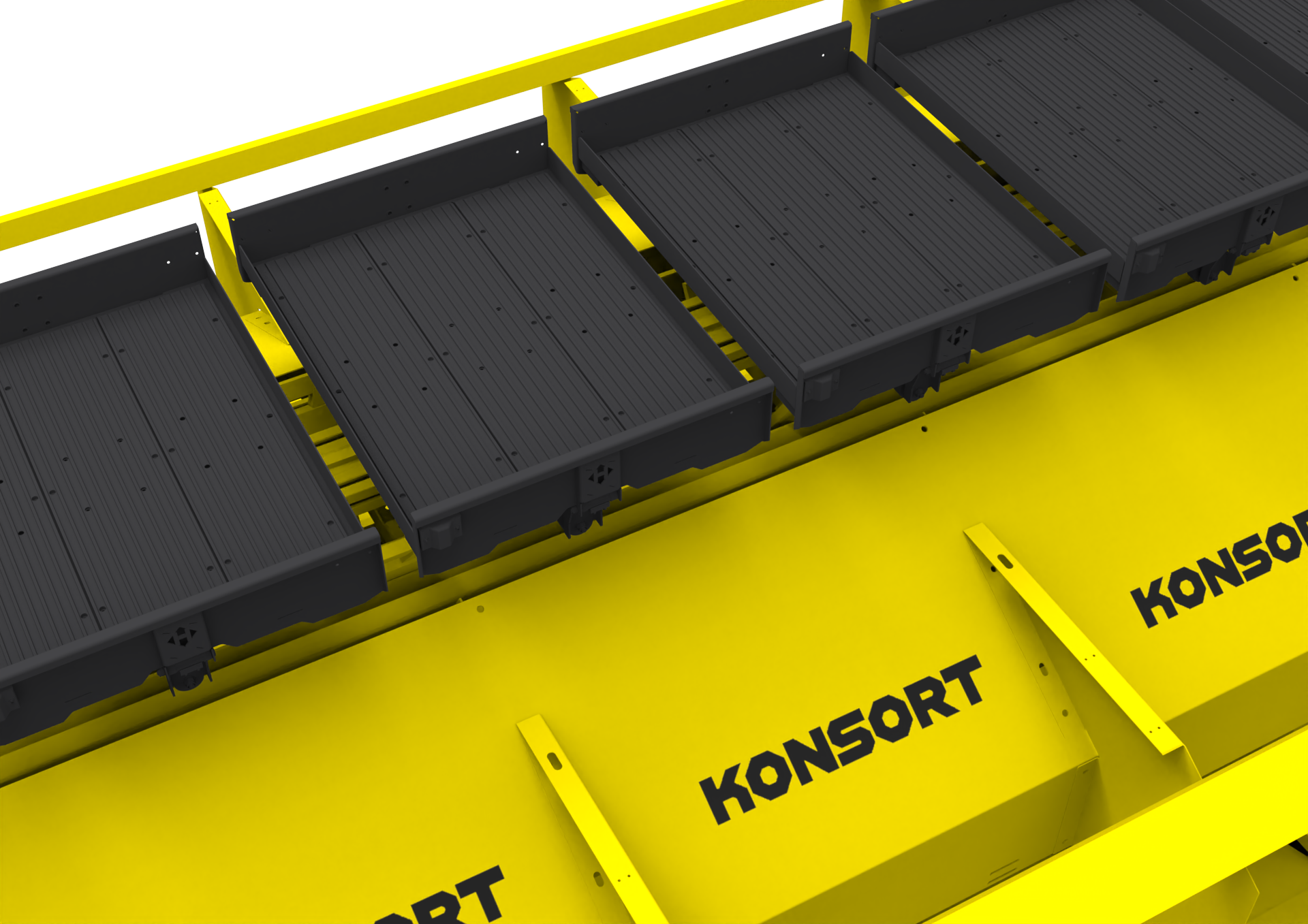

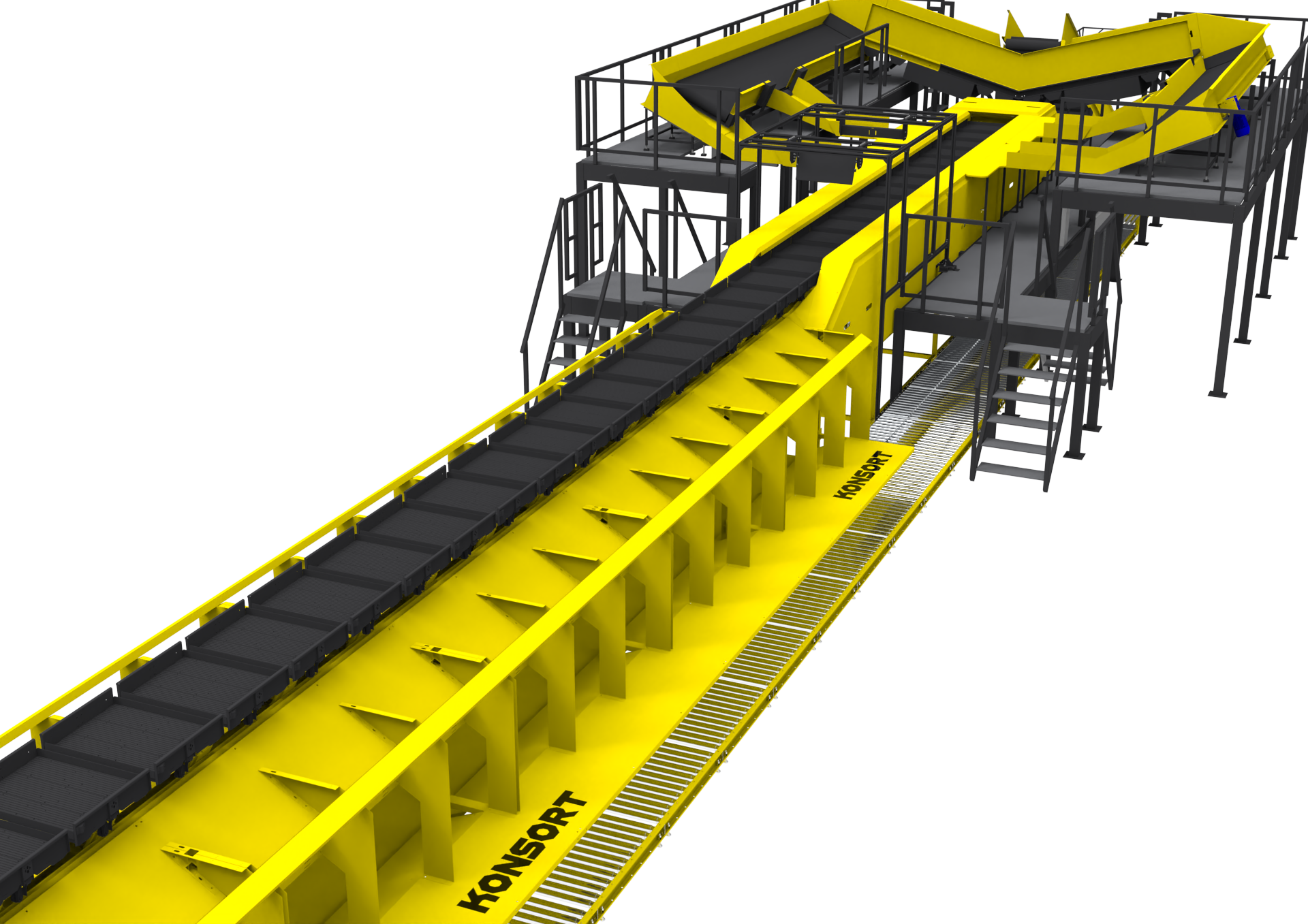

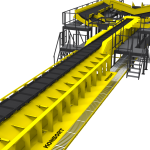

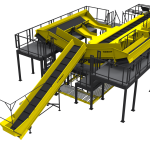

LR-sorter (modular sorting system with sliding trays)

LR-sorter – modular sorting system with sliding trays for logistics automation and parcel distribution

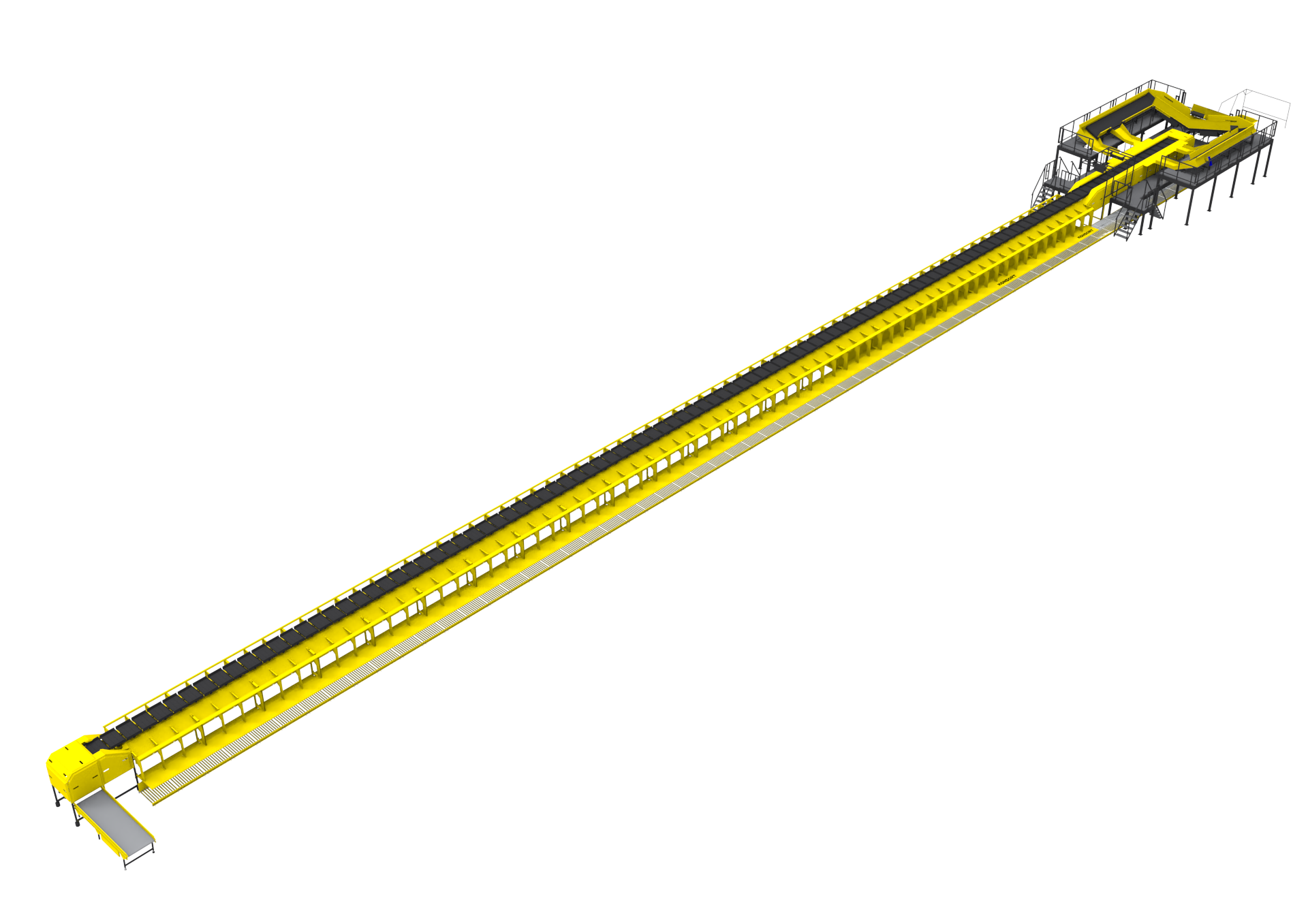

Looking for an efficient solution to streamline your parcel sorting process? The LR-sorter from KONSORT is a modern, high-performance modular sorting system designed for automated parcel distribution at warehouses, fulfillment centers, postal hubs, and production facilities. It adapts to your operational needs and delivers fast, accurate, and space-efficient sorting for high volumes of small shipments.

What is the LR-sorter used for?

The LR-sorter is designed to sort a wide range of small packages into designated output ports with minimal manual intervention. Thanks to its modular construction and smart scanning system, it integrates easily into existing logistics workflows and warehouse layouts.

You can buy the LR-sorter directly from the manufacturer in Ukraine, ensuring competitive pricing, expert consultation, and full after-sales support.

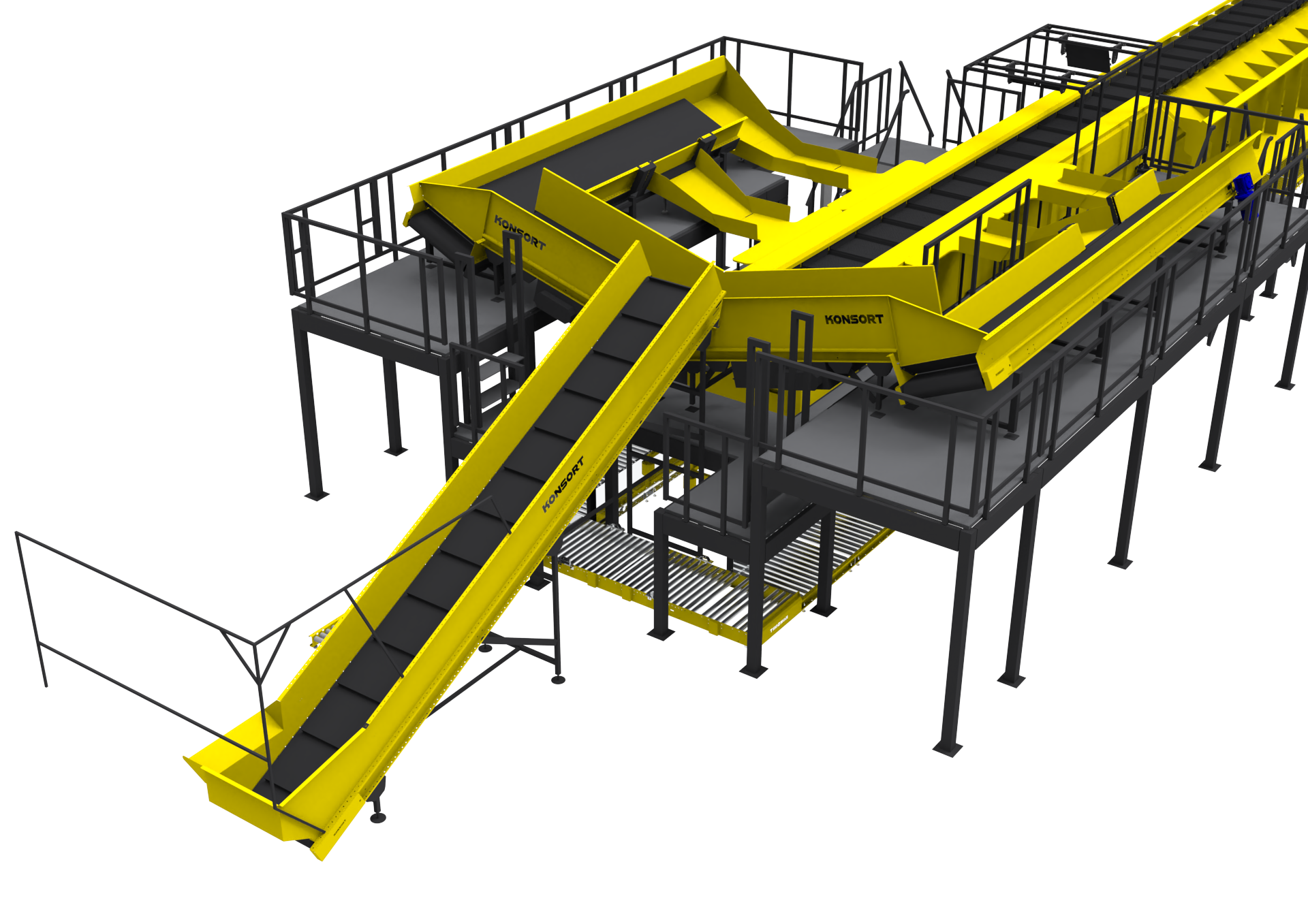

How the LR-sorter works — step by step

The system operates through a fully automated process:

-

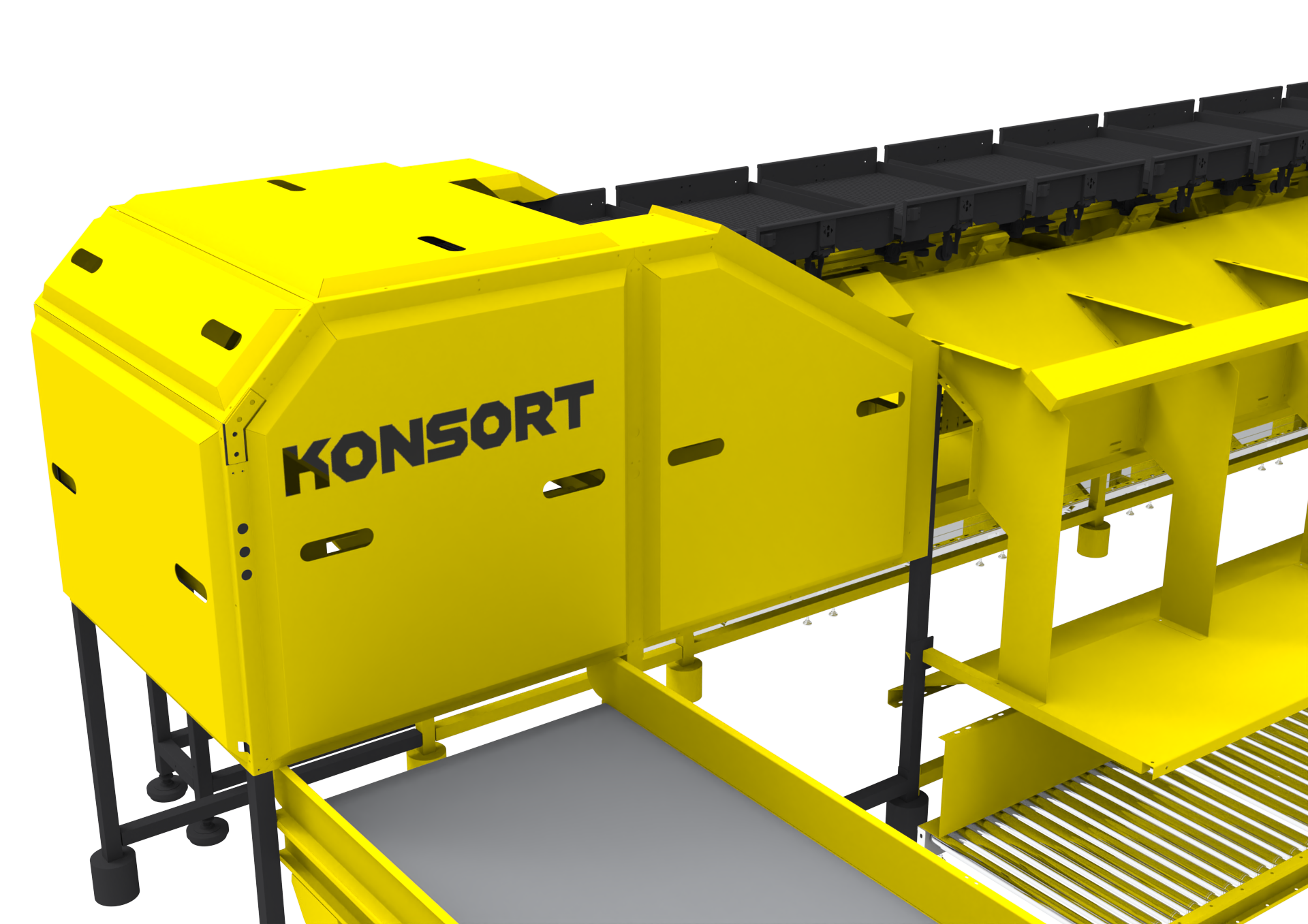

A polybox with unsorted parcels is transported by a roller conveyor to a dumping unit.

-

The dumping unit unloads parcels onto the main belt conveyor.

-

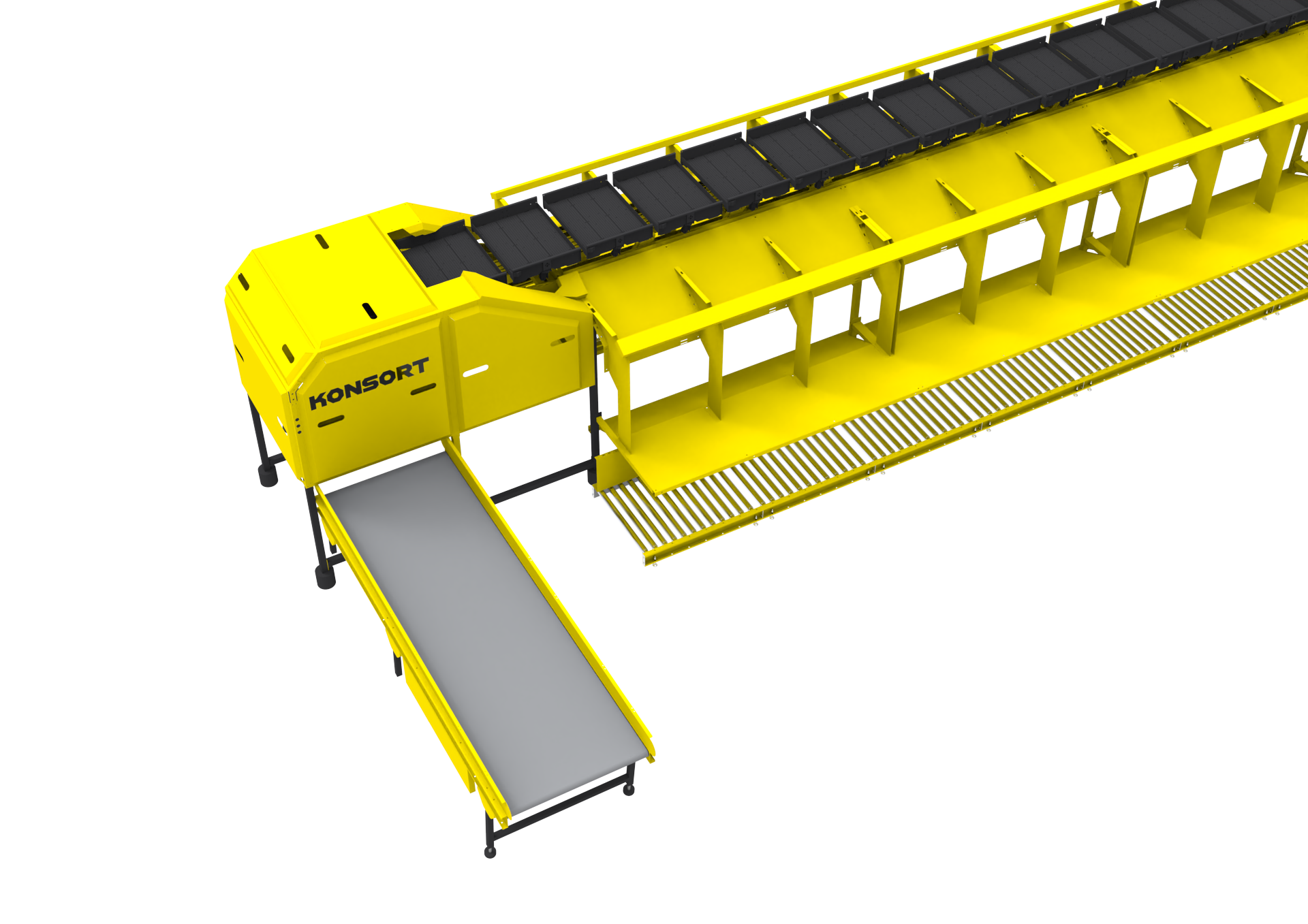

The conveyor lifts the parcels up and splits them into two flows — left and right.

-

8 operators (4 on each side) place the parcels barcode-side up on the sorting line.

-

A barcode scanner automatically scans each parcel and sends the data to the control system.

-

Each scanned parcel is automatically routed to the correct output port, where a sliding tray guides it into the appropriate polybox.

-

Once the polybox is full, the operator pushes it onto the outbound conveyor and replaces it with a new one supplied by the automated feed system.

-

The filled polybox is sent to the correct dispatch direction and continues its journey to the destination city.

⏱️ Average processing time per parcel: up to 3 minutes — enabling high-throughput parcel handling with minimal delay.

✅ Key advantages of the LR-sorter

-

Space-saving design — the dual-side sorting setup makes maximum use of your terminal’s available floor area.

-

Modular configuration — scale the system easily by adding sorting ports or modifying the layout.

-

Quick route reconfiguration — adapt port assignments in minutes to meet changing logistics needs.

-

Flexible parcel handling — supports various shapes and sizes, from soft mailers to rigid boxes.

-

Fully automated sorting process — reduces labor costs and human error.

-

Robust, reliable, service-ready — engineered by Ukrainian professionals to meet real-world logistics demands.

-

Custom-built for your business — whether you run an e-commerce fulfillment center or a high-volume sorting hub.

Where is the LR-sorter already used?

LR-sorters are actively operating in logistics terminals across:

-

Ternopil

-

Lviv

-

Kyiv region etc.

These systems have proven their reliability in environments with thousands of daily shipments, including during peak load hours.

Custom engineering & project implementation

Our engineers at KONSORT design each LR-sorter based on your specific operational needs. We evaluate:

- Available warehouse or terminal space

- Parcel volume and shipment types

- Number of required destinations and output ports

- Speed and automation level needed

✅ We deliver the best warehouse automation solution tailored to your business.

Buy LR-sorter — price directly from the manufacturer

With KONSORT, you can order the LR-sorter at factory-direct prices, with no intermediaries. We offer:

-

Free expert consultation

-

Turnkey project execution

-

On-site installation and commissioning

-

Warranty and after-sales support

We work with logistics companies, postal operators, online marketplaces, and industrial warehouses of all sizes.

Get your LR-sorter today

Ready to boost your parcel sorting performance? Fill out the request form on our website or call us directly — our team will help you configure the optimal modular sorting system with sliding trays for your warehouse or logistics center.

Improvement of production organization and management by up to 80%

Improvement of production organization and management by up to 80%  Increase in productivity by up to 70%

Increase in productivity by up to 70%  Reduction of production costs by up to 30%

Reduction of production costs by up to 30%  Reduction of risks related to the human factor by up to 35%

Reduction of risks related to the human factor by up to 35% - For sorting small parcels at logistics centers and warehouses

- For sorting small parcels at postal and retail company terminals

- European design ensures a professional and clean appearance

- Possibility to expand the sorting line

- Automation of the cargo sorting process

- Custom manufacturing based on individual parameters

- Use of European components