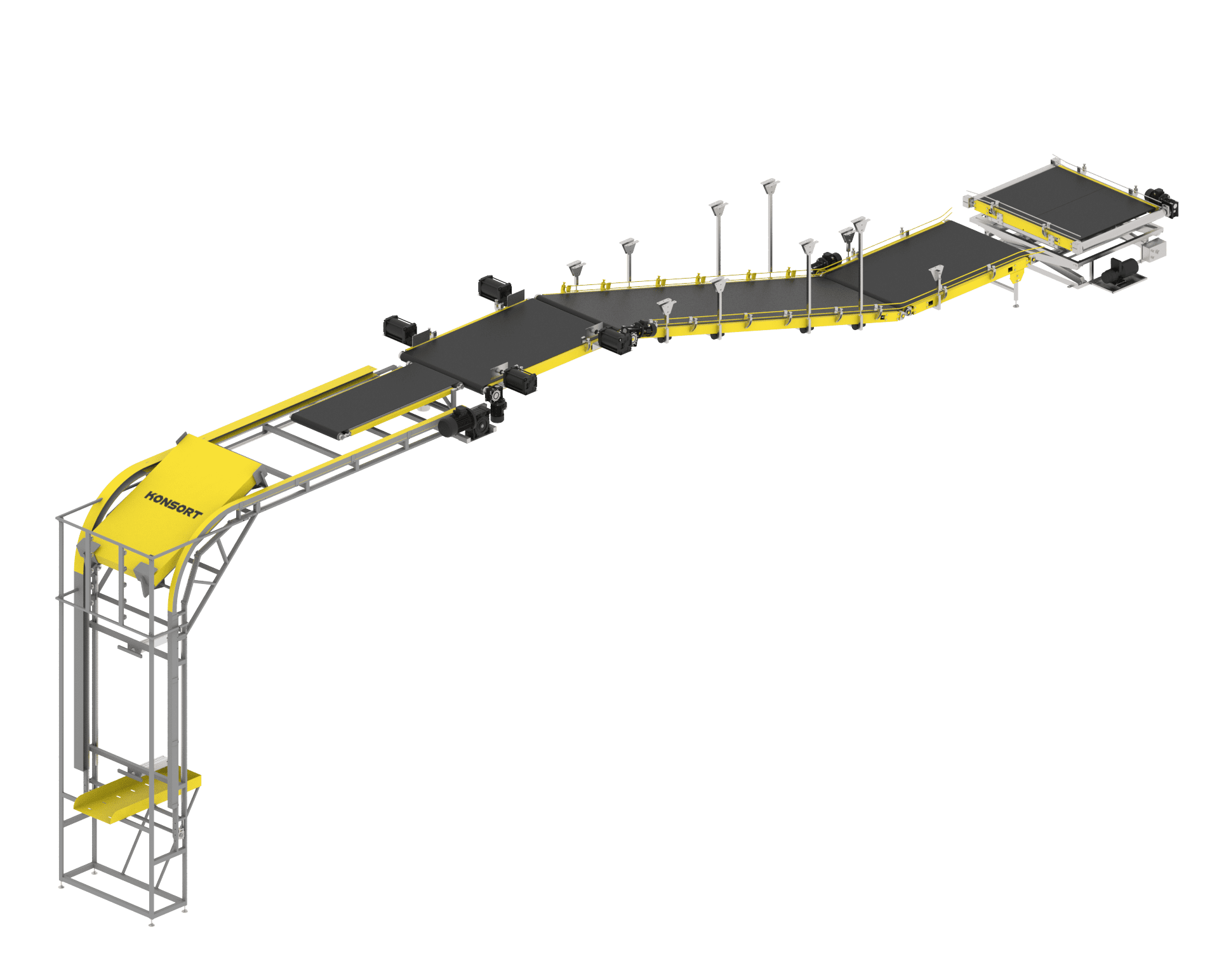

Line for door transportation and positioning

Order a Door Transporting and Positioning Line from the Manufacturer (Ukraine)

Description

The Door Transporting and Positioning Line from the Ukrainian manufacturer KONSORT is a modern, high‑efficiency solution for companies aiming to automate the feeding, moving, and precise positioning of door panels in production lines. Designed for continuous operation in industrial workshops, the equipment ensures high positioning accuracy and consistent operational quality.

The equipment is made of structural steel with a powder‑coated finish (RAL 7046). Power supply connection — 380 V. Drive is provided by a gear motor with a power range of 0.55 kW to 0.75 kW. A smooth green PVC belt is used for transportation.

Two operation modes

First mode: Doors are automatically received from the customer’s packaging machine. Maximum feed rate — 1 unit/minute.

Second mode: Doors are manually fed onto the lifting‑turning conveyor no more than 1 unit/minute.

The electrical control cabinet is located on the second floor. The control panel features a mode selector switch (first/second mode), start/stop buttons, audible and visual alarms, an intercom system, and an emergency stop button with mechanical latching.

Components:

- Lifting‑turning conveyor

- Belt conveyor ×2

- Belt conveyor with door centering system

- Belt conveyor with lowering and accumulation system

Advantages:

✅ Customized design — tailored to the specifics of your production

✅ Automation reduces manual labor costs and increases productivity

✅ Smooth transport without jerks or damage, ensuring product quality preservation

Order the Door Transporting and Positioning Line today and make your production process faster, more precise, and more cost‑efficient!

Improving in the organization of production and management by 75%

Improving in the organization of production and management by 75%  Productivity increase up to 80%

Productivity increase up to 80%  Lower production costs by 40%

Lower production costs by 40%  Reduction in human-related risks by 20%

Reduction in human-related risks by 20% - For transporting door leaves or other panels

- Production workshops in the furniture and construction industries

- Automation of feeding and positioning door leaves during the assembly and finishing process

- Reduction of human factor influence — fewer positioning errors

- Increased productivity — continuous operating cycle

- There is possibility to complete the line with extra components if necessary

- Two-mode operation line

- European components are used