Lecithin bottling line

Order a Lecithin Filling Line for Drums from the Manufacturer (Ukraine)

Description

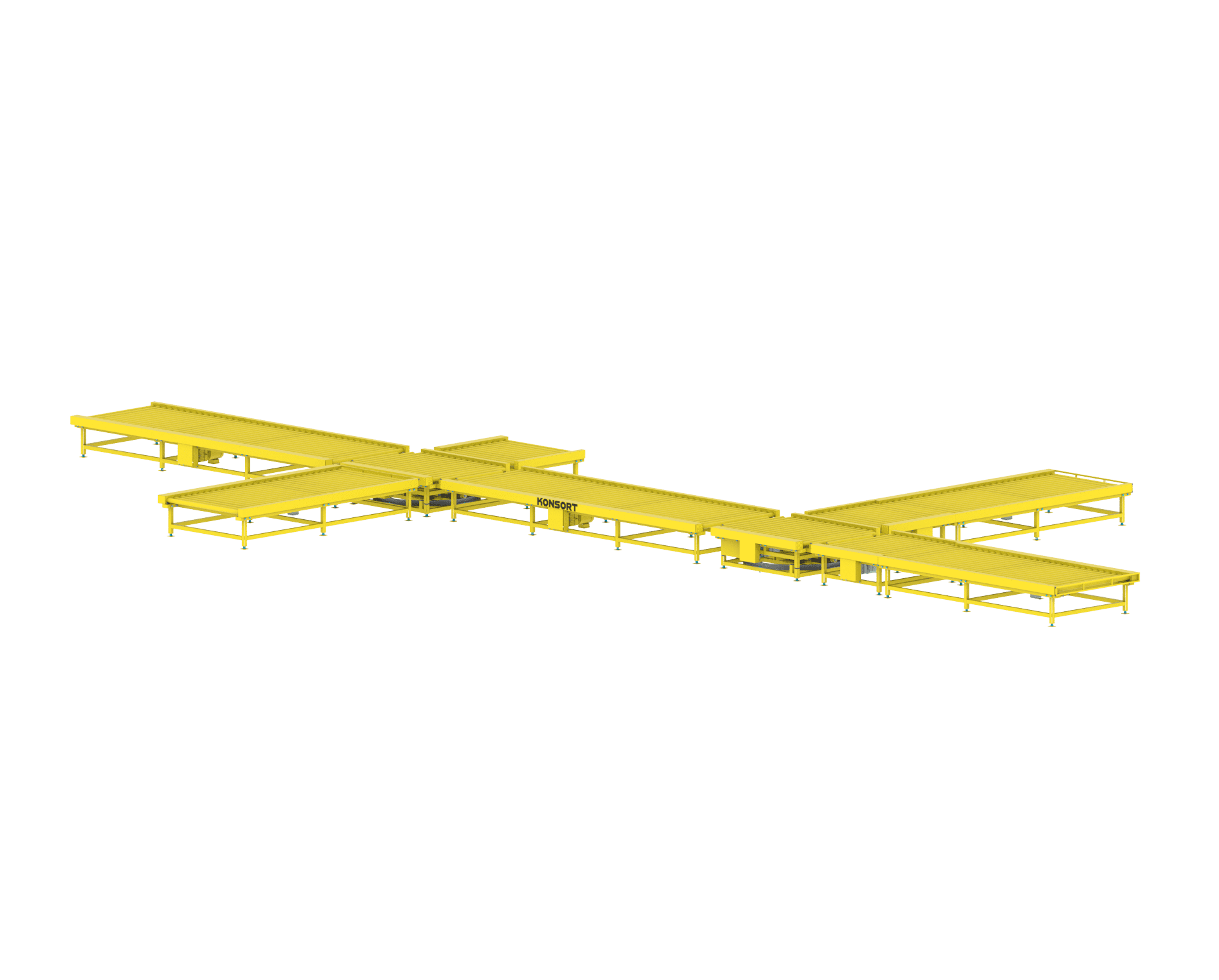

The lecithin filling line for drums from the Ukrainian manufacturer KONSORT is a modern automated solution for efficient and safe filling of liquid lecithin into metal or plastic drums of various volumes. The equipment ensures high productivity, precise dosing, and stable operation, which is especially important for food industry enterprises and production facilities where uninterrupted product supply and high-quality filling are required.

Components:

The line consists of a system of roller conveyors and a turntable. Materials: roller conveyor frame — cold galvanizing, rollers — electro-galvanizing. The equipment is equipped with gear motors from 1.5 to 3 kW and frequency converters with similar specifications. Power supply connection — 380 V.

Installed electrical equipment includes: control cabinet, motion control sensors, power cables, emergency stop system, controller, audio-visual alarm, push-button control station.

Operating principle:

The operator places a pallet on conveyor N1 and presses the Start button on the push-button control station. The station is located in the dirty zone and equipped with an emergency STOP button that immediately stops all conveyors if necessary.

Next, the operator presses the “Pallet Feed” button on the filling machine. This activates conveyor N4, which delivers the pallet to the filling position. Once the pallet from conveyor N4 reaches the filling machine, conveyors N3, N2, and N1 are automatically engaged.

When it is necessary to remove the finished product, the operator presses the “Full Drum Discharge” button. At this moment, conveyor N5 starts, transporting full drums and automatically stopping once the filling sensor is triggered. The next start of conveyor N5 is only possible after the operator presses the “Full Drum Discharge” button again on the filling machine.

This automation system allows you to:

✅Reduce loading and unloading time

✅Minimize manual labor

✅Ensure safe and controlled operation of the entire line

✅Optimize the lecithin filling process into drums

Order your lecithin filling line for drums from KONSORT today! Ensure stable production performance, reduce costs, and increase efficiency!

Improving in the organization of production and management by 55%

Improving in the organization of production and management by 55%  Productivity increase up to 80%

Productivity increase up to 80%  Lower production costs by 40%

Lower production costs by 40%  Reduction in human-related risks by 20%

Reduction in human-related risks by 20% - Enterprises producing oil and fat products

- Enterprises producing food additives

- At enterprises of the oil refining industry

- Automation of the filling process — significant reduction of manual operations and operator errors

- High dosing accuracy — control of lecithin quantity in each barrel

- Compatibility with production lines — easily integrates with conveyors and feeding systems

- Equipment made of high‑quality materials resistant to viscous liquids