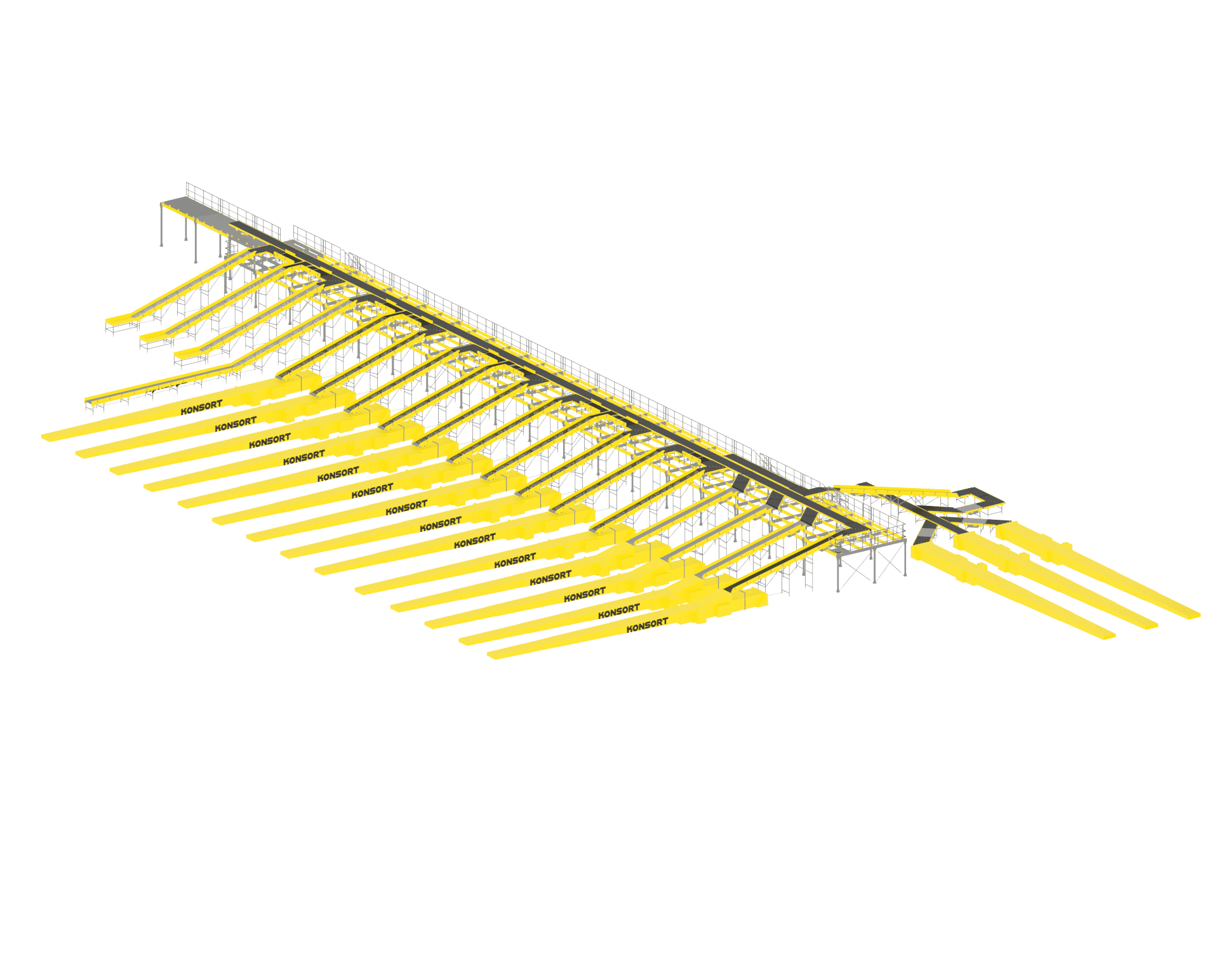

Cargo sorting line (from 2 to 60 kg)

Order a Cargo Sorting Line (from 2 to 60 kg) from the Manufacturer (Ukraine)

Description

The Cargo Sorting Line (from 2 to 60 kg) is an innovative automated solution from Ukrainian manufacturer KONSORT that enables fast, accurate, and continuous sorting of a wide range of cargo. The system is designed for handling and transporting goods across various industries where high processing speed, minimal manual labor, and increased productivity are required.

Implementing this line optimizes workflows, reduces the time needed for logistics operations, and ensures accurate delivery of cargo to the next stages of packaging, dispatch, or storage.

Operating principle:

The sorting line operates on a pneumatic principle, where cargo is distributed by compressed air supplied from a compressor to drop mechanisms actuated by pneumatic cylinders.

The system supports sorting of cargo and parcels into up to 120 destinations (three branches with 40 ports each). During transportation, cargo passes through pre-sorting, identification, and barcode scanning stages, after which it is automatically directed to the appropriate sorting branch according to the destination code. The cargo is then delivered to the corresponding port.

The throughput capacity of a single level is up to 3,600 items per hour, with the total system capacity reaching up to 7,200 items per hour.

The configuration of the line can be adapted to meet specific capacity and destination requirements.

Components:

- Loading conveyor – 1 pc.

- Conveyor with pneumatic diverter – 3 pcs.

Why choose KONSORT’s Cargo Sorting Line?

✅ Over 18 years of experience in conveyor system manufacturing

✅ In-house production in Ukraine — guaranteed quality and tailored solutions

✅ Customization to client needs — designed to match specific business requirements

✅ Professional installation and servicing — full project cycle from design to commissioning

✅ Technical support and expert consultation

Order your cargo sorting line today and take a step towards full business automation!

KONSORT’s modern sorting system will help you increase order processing speed, reduce manual labor costs, and eliminate sorting errors. It is an investment that will quickly pay off by boosting productivity, optimizing logistics, and ensuring consistent customer service quality!

Improving in the organization of production and management up to 80%

Improving in the organization of production and management up to 80%  Productivity increase up to 70%

Productivity increase up to 70%  Lower production costs up to 30%

Lower production costs up to 30%  Reduction in human-related risks up to 35%

Reduction in human-related risks up to 35% - For order processing optimization and reduction of dispatch time

- For cargo sorting at postal company terminals

- Easily connects to existing product transportation and handling systems

- Suitable for various types of products and integrates into existing lines

- Minimizes manual sorting, reduces the impact of human factors and errors

- Possibility of manufacturing according to individual specifications

- European components are used