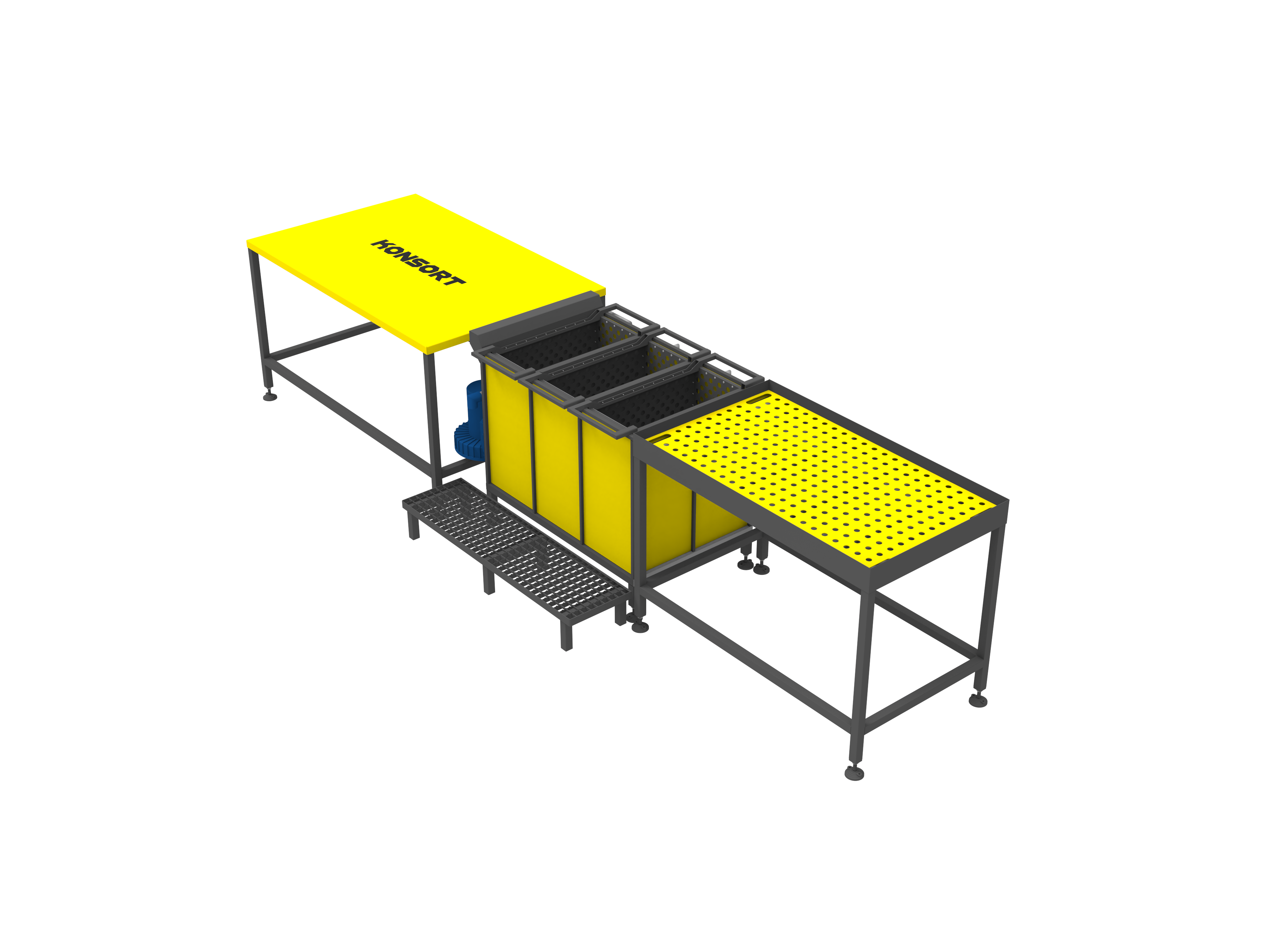

Bubble washer for egg disinfection

The bubble washer for egg disinfection is a specialized piece of equipment designed for gentle and efficient cleaning of eggs from dirt and microorganisms prior to packaging or further processing. It is an essential washing machine for the food industry, ensuring compliance with hygiene and food safety standards.

Purpose and Operating Principle

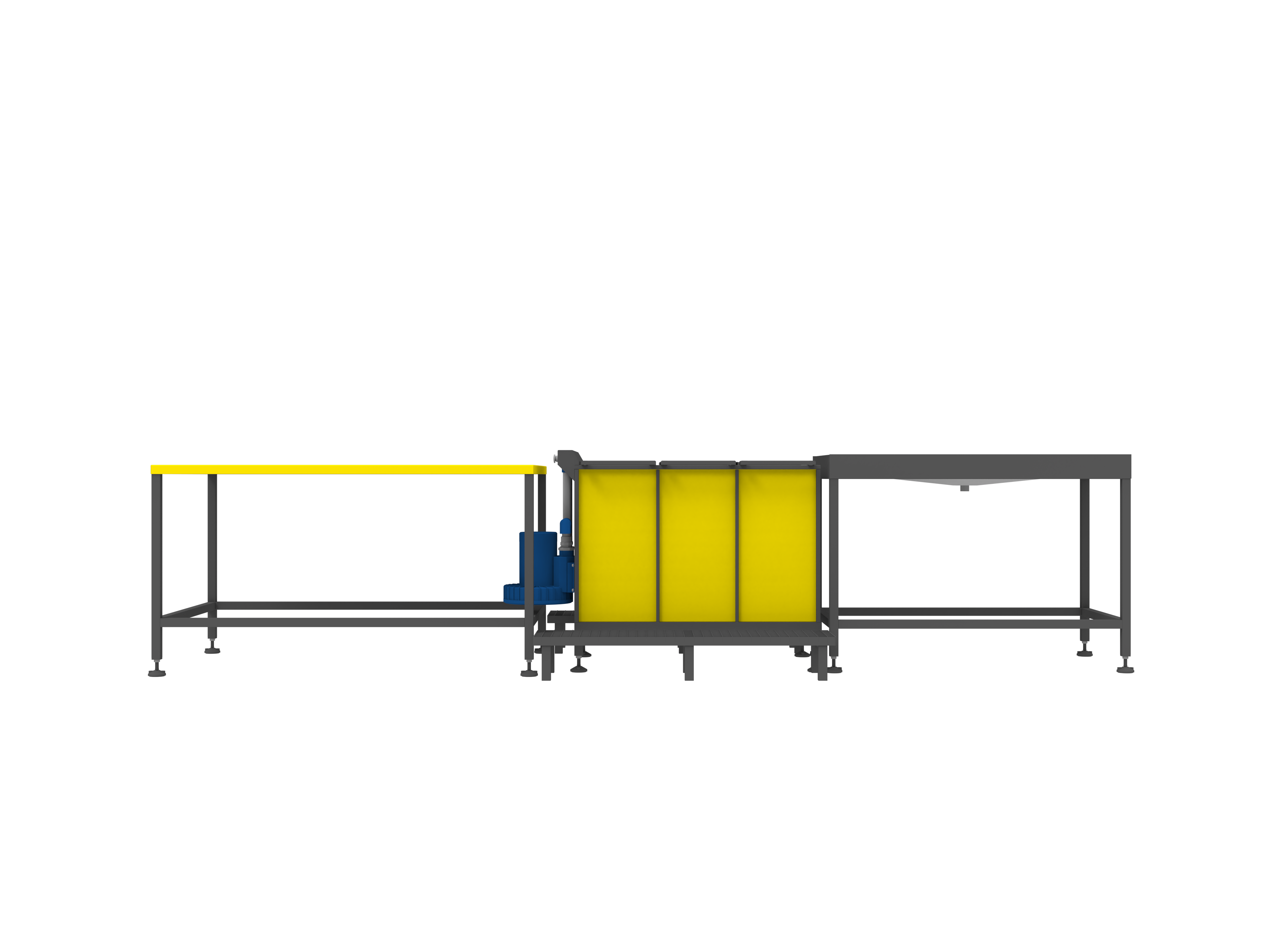

This washer is designed for delicate cleaning and disinfection of eggs. The structure is divided into three independent sealed sections using stainless steel partitions. Each section has its own drainage, preventing cross-contamination.

Once activated, the barbotage system engages in all three sections simultaneously, generating millions of tiny air bubbles that gently clean the product surface.

Product Loading and Treatment

Eggs are preloaded into plastic trays, which are stacked two rows high, with 10 units per row.

The trays are placed into a mesh shelf, offering stability and easy access to each tray level.

The degree of washing is manually controlled — the operator moves the shelf between sections based on the required disinfection time.

Adjustment and Additional Equipment

-

Airflow intensity (bubble strength) can be adjusted to suit the cleaning requirements.

-

The operator may set the power level depending on the product type or contamination degree.

-

Optional accessories such as service tables and ladders are available for safer and easier operation.

If you’re looking for industrial food-grade washing equipment that ensures effective egg cleaning, long-lasting performance, and compliance with international standards — trust KONSORT.

Order directly from the manufacturer — no middlemen, guaranteed quality, and a custom-tailored approach.

Contact us today to get a personalized offer!

Improving the washed product quality, reducing damage of raw materials

Improving the washed product quality, reducing damage of raw materials  Productivity increase up to 70%

Productivity increase up to 70%  Workforce optimization up to 30%

Workforce optimization up to 30%  Reduction in human-related risks

Reduction in human-related risks - Enterprises specialized in pre-sale vegetables and berries preparation

- Enterprises and factories specialized in processing, packing, and freezing products

- European design

- Manufacturing process automation, high-quality result

- Thorough and gentle cleaning

- Payback in 9 months