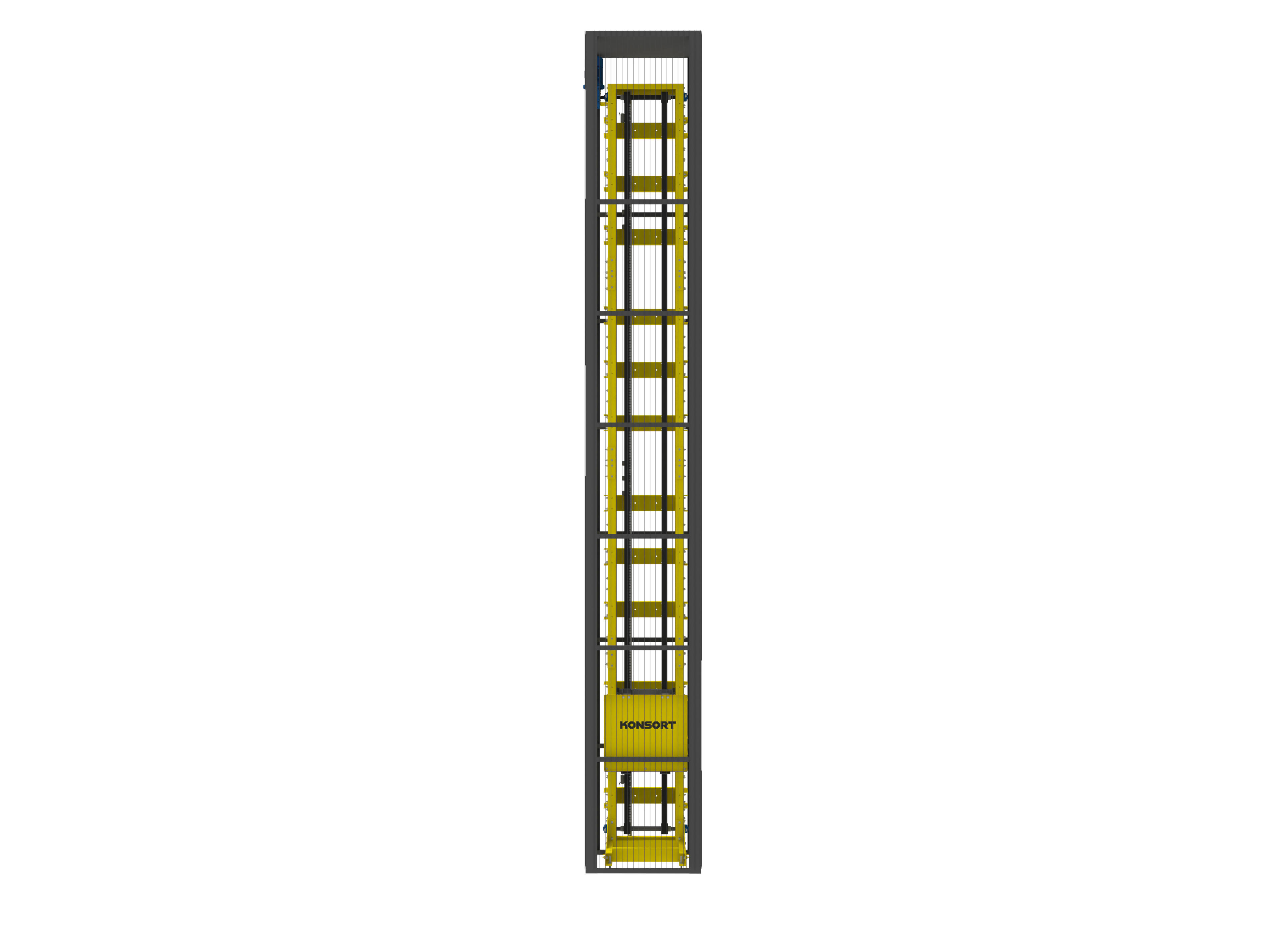

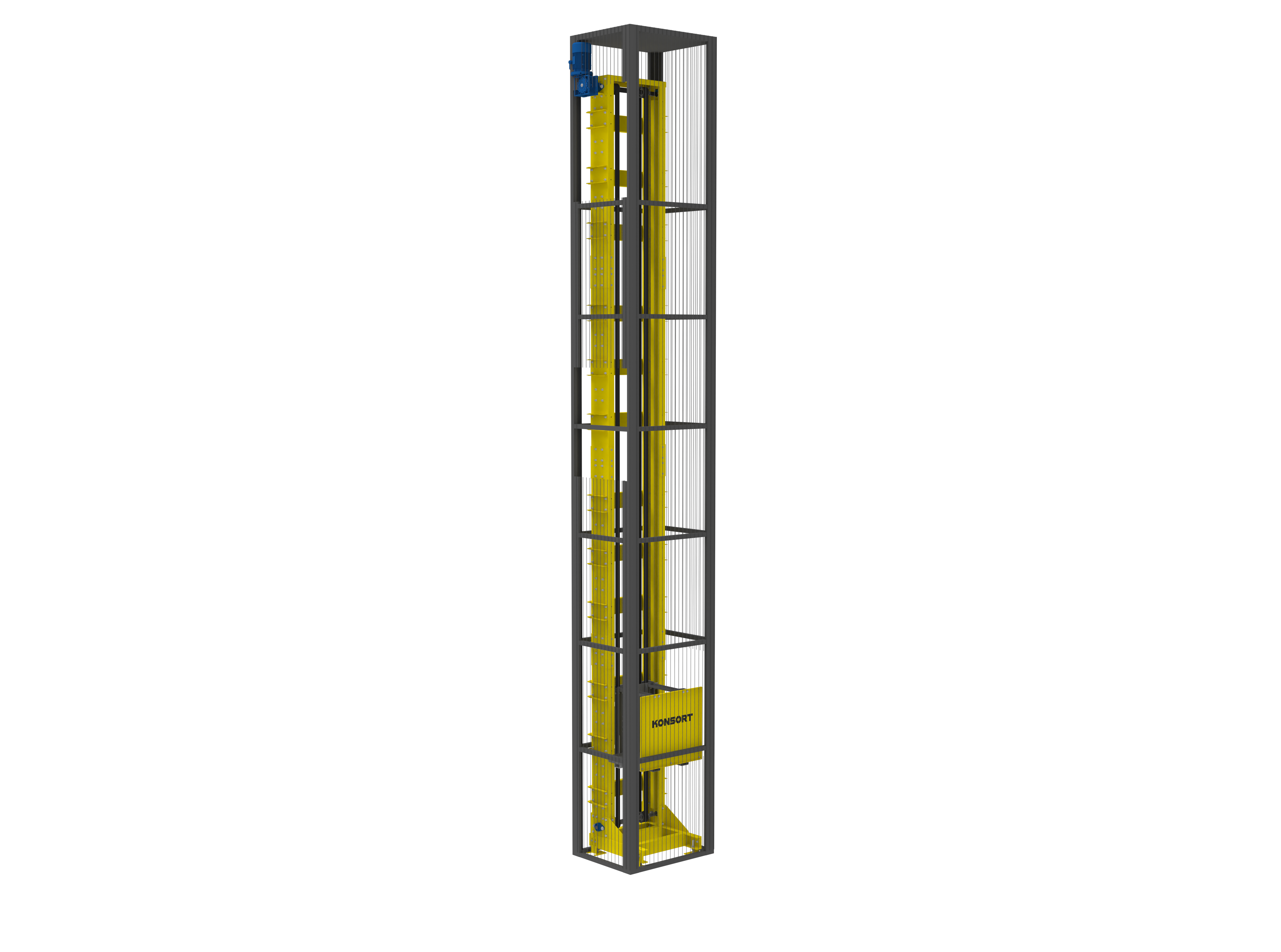

Vertical cantilever conveyor

Vertical cantilever conveyor – an efficient solution for production transport automation

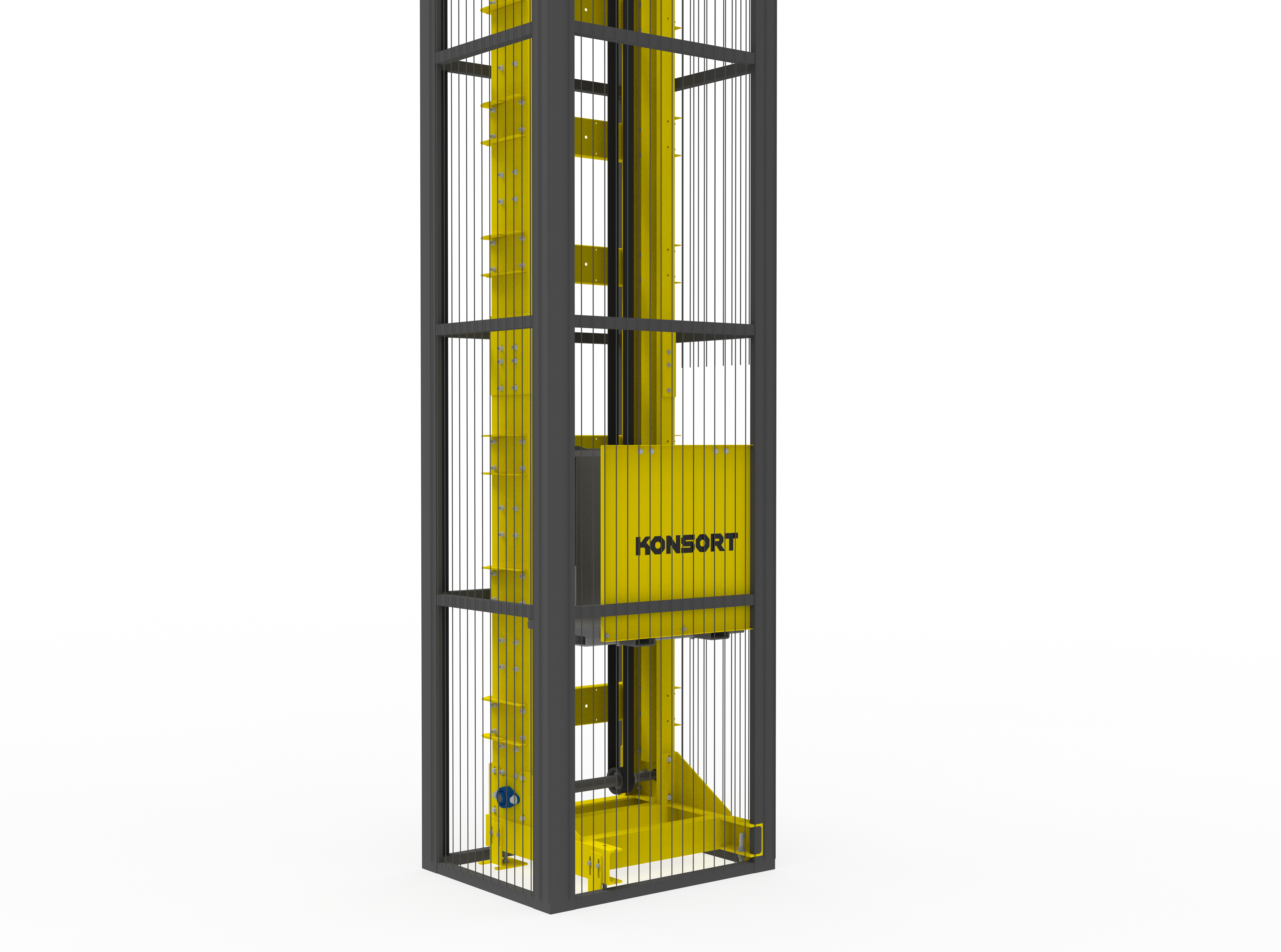

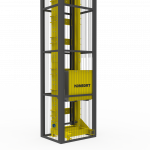

The vertical cantilever conveyor by KONSORT is a modern industrial solution designed for vertical transfer of goods between different levels of the production process. This equipment helps to optimize space utilization and ensures uninterrupted product flow without the need for complex lifting mechanisms.

Key Advantages of the Vertical Cantilever Conveyor

- Space optimization: Ideal for facilities with limited floor space — maximizes vertical layout.

- High performance: Ensures consistent and reliable product transport even under intensive operation.

- Reduced human error: Process automation minimizes the risk of operator mistakes.

- Resource efficiency: Reduces labor costs and accelerates production workflows.

- Durability and reliability: Manufactured from high-grade materials compliant with ISO and CE standards.

- System integration: Easily connects with horizontal conveyors, sorting lines, and packaging equipment.

Products suitable for vertical conveying

The conveyor is engineered for handling a wide range of items, including:

- Packed goods in boxes or crates

- Light to medium-sized pallets

- Bagged materials (e.g. flour, sugar, granulated ingredients)

- Finished products at the sorting and packing stage

Why Choose KONSORT Conveyors?

✅ Over 18 years of experience in conveyor system manufacturing

✅ Custom engineering based on specific client requirements

✅ ISO and CE certified materials and components

✅ 18-month equipment warranty

✅ Nationwide service and support across Ukraine

The KONSORT vertical cantilever conveyor is more than just equipment — it’s a long-term investment in your business’s productivity, reliability, and automated growth.

Space optimization, resource saving

Space optimization, resource saving  Integration with other systems

Integration with other systems  Strength and durability, high performance

Strength and durability, high performance  Reducing the risk of the human factor

Reducing the risk of the human factor - Logistics and warehousing

- Wholesale and retail

- Food industry

- Pharmaceutical industry

- Production of building materials

- European design and certification

- High quality at affordable prices

- Speed of order production

- Warranty on equipment and service