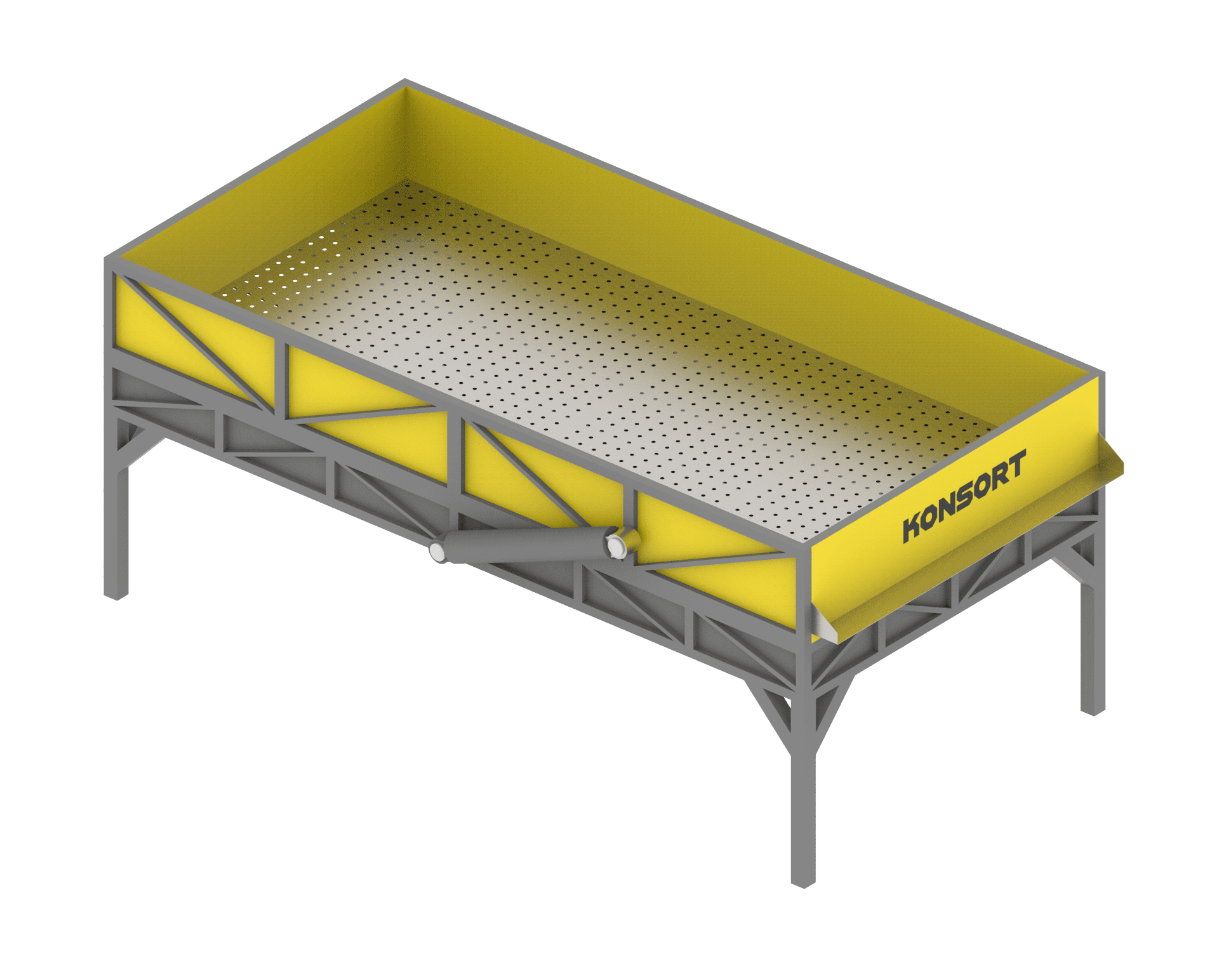

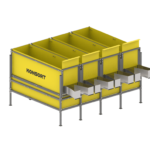

Drying chamber for nuts

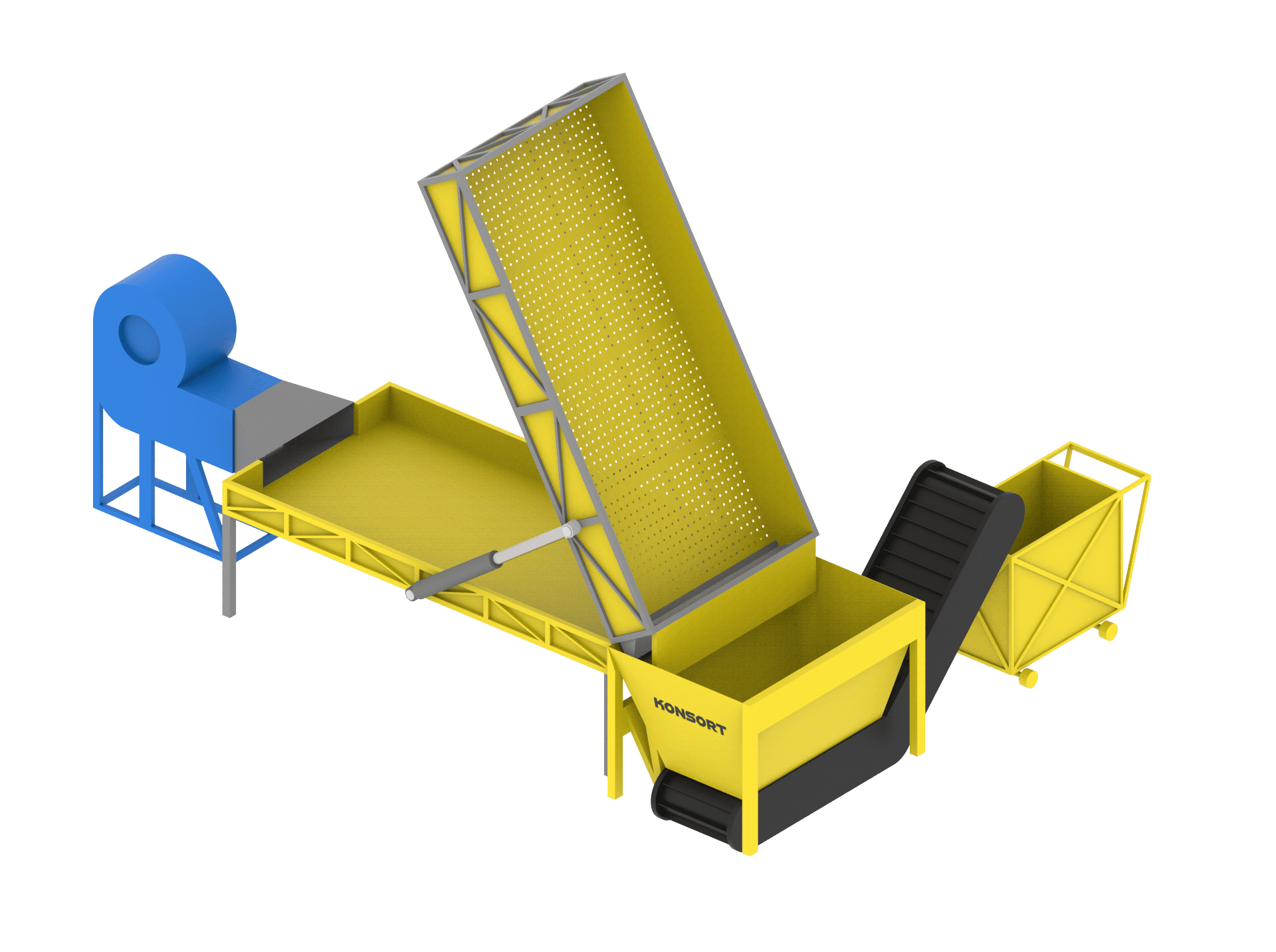

The nut drying chamber by Ukrainian manufacturer KONSORT is a professional piece of equipment designed for the efficient drying of nuts (such as walnuts, hazelnuts, peanuts, and others), as well as various other food products. The chamber preserves the flavor, texture, and quality of raw materials without compromising the final product.

Purpose of the drying chamber:

The chamber is intended for:

-

Industrial nut drying — even moisture removal without overheating;

-

Drying of berries, vegetables, fruits, and seeds;

-

Use in food processing facilities;

-

Increasing shelf life and reducing product moisture content.

This is a universal solution suitable for both small farms and large-scale manufacturing enterprises.

Advantages of the KONSORT drying chamber:

✅ High energy efficiency — minimal power consumption with maximum productivity;

✅ Drying process automation — control over temperature, humidity, and time;

✅ Uniform drying — specialized design ensures even treatment of all product batches;

✅ Food-grade materials and quality construction — made from safe materials compliant with food industry standards;

✅ Adjustable for different products — easily configured for various types of raw material.

Why buy a nut drying chamber in Ukraine from KONSORT?

KONSORT offers:

-

Over 15 years of experience in food industry equipment manufacturing;

-

In-house production in Ukraine with the option to order directly from the manufacturer at a competitive price;

-

Guaranteed quality, full technical support, and consultation at every stage.

Purchasing a nut drying chamber in Ukraine today means investing in reliability, energy efficiency, and consistent product quality. We offer factory-direct pricing with no markup.

Reducing product waste

Reducing product waste  Productivity increase up to 70 %

Productivity increase up to 70 %  Workforce optimization up to 30%

Workforce optimization up to 30%  Reduction in human-related risks

Reduction in human-related risks - Farming enterprises — for seasonal drying of walnuts, hazelnuts, and almonds

- Processing plants — for large-scale product preparation before packaging

- Agricultural companies — for drying raw materials prior to storage or transport

- Healthy food factories — for gentle drying of natural snacks

- European design

- Process automation

- Preservation of product taste