Fish processing line

Fish processing line

Description

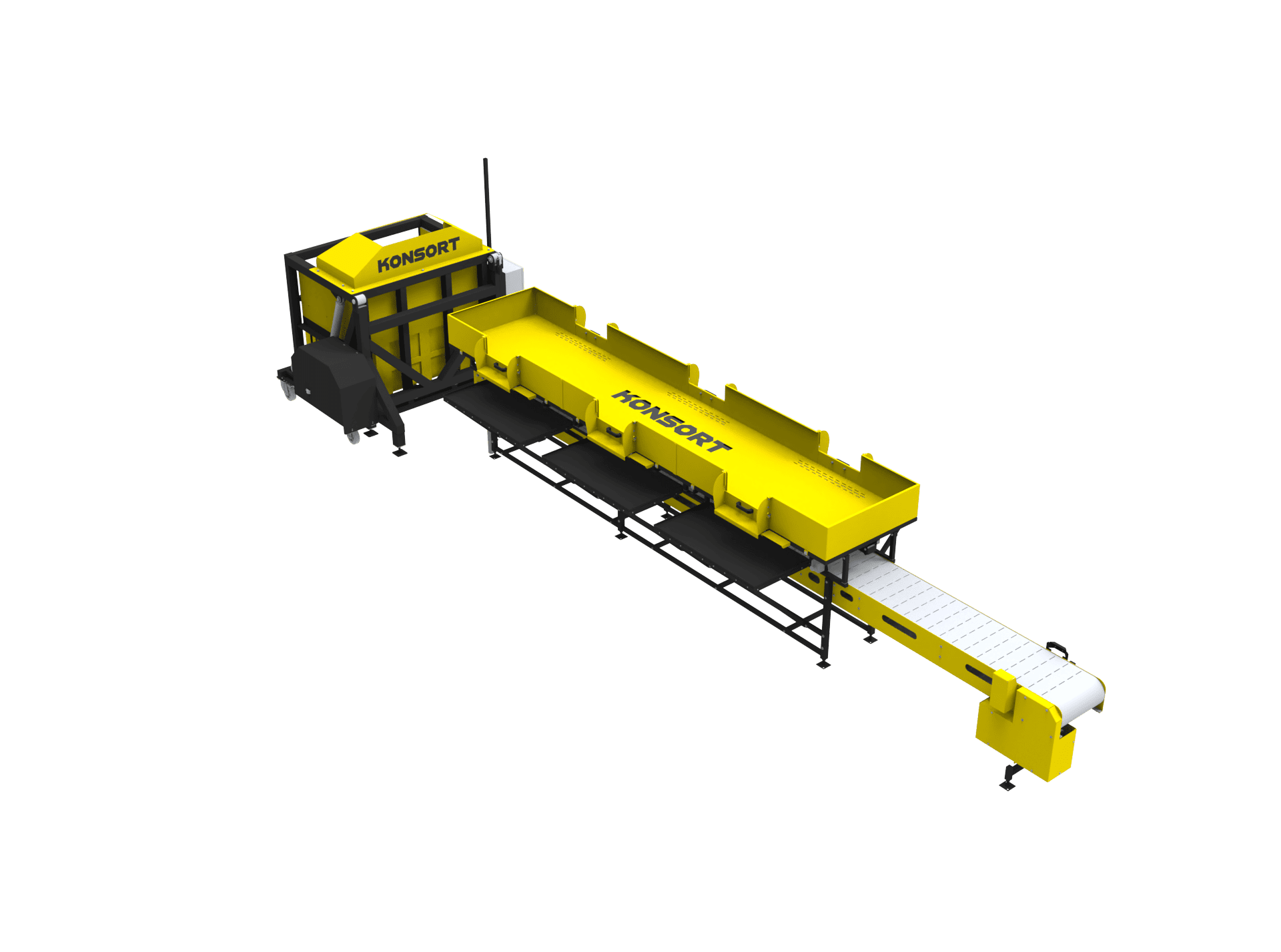

The fish processing line is an efficient solution for automating the sorting, gutting, and transportation of fish in the food processing industry. It reduces processing time and improves the quality of fish preparation for packaging or further processing.

The process starts with the gradual unloading of fish from a container onto the upper tier of the inspection table using a tipping unit. Operators then manually select and gut the fish on stainless steel tables. After processing, the cleaned fish is placed on a modular conveyor for further transportation to storage boxes.

Components:

- Container tipper – automated fish unloading

- Upper tier of the inspection table – for sorting and processing fish

- Lower tier of the inspection table – for accumulation and further processing

Advantages:

✅ Automation of the fish unloading and processing process

✅ Stainless steel construction for compliance with sanitary standards

✅ Optimization of the workflow, reducing manual labor

✅ Reliable and durable design

✅ Easy integration into existing production lines

Order your fish processing line directly from the manufacturer – efficient fish handling for your enterprise at the best price!

Improving in the organization of production and management by 65%

Improving in the organization of production and management by 65%  Productivity increase up to 60%

Productivity increase up to 60%  Lower labour costs by 78%

Lower labour costs by 78%  Reduction in human-related risks by 40%

Reduction in human-related risks by 40% - Pharmaceutical companies

- Fish processing plants

- Fish canning plants

- European design provides a professional and clean look

- Durable powder coating

- There is possibility to complete the line with extra components if necessary

- European components are used