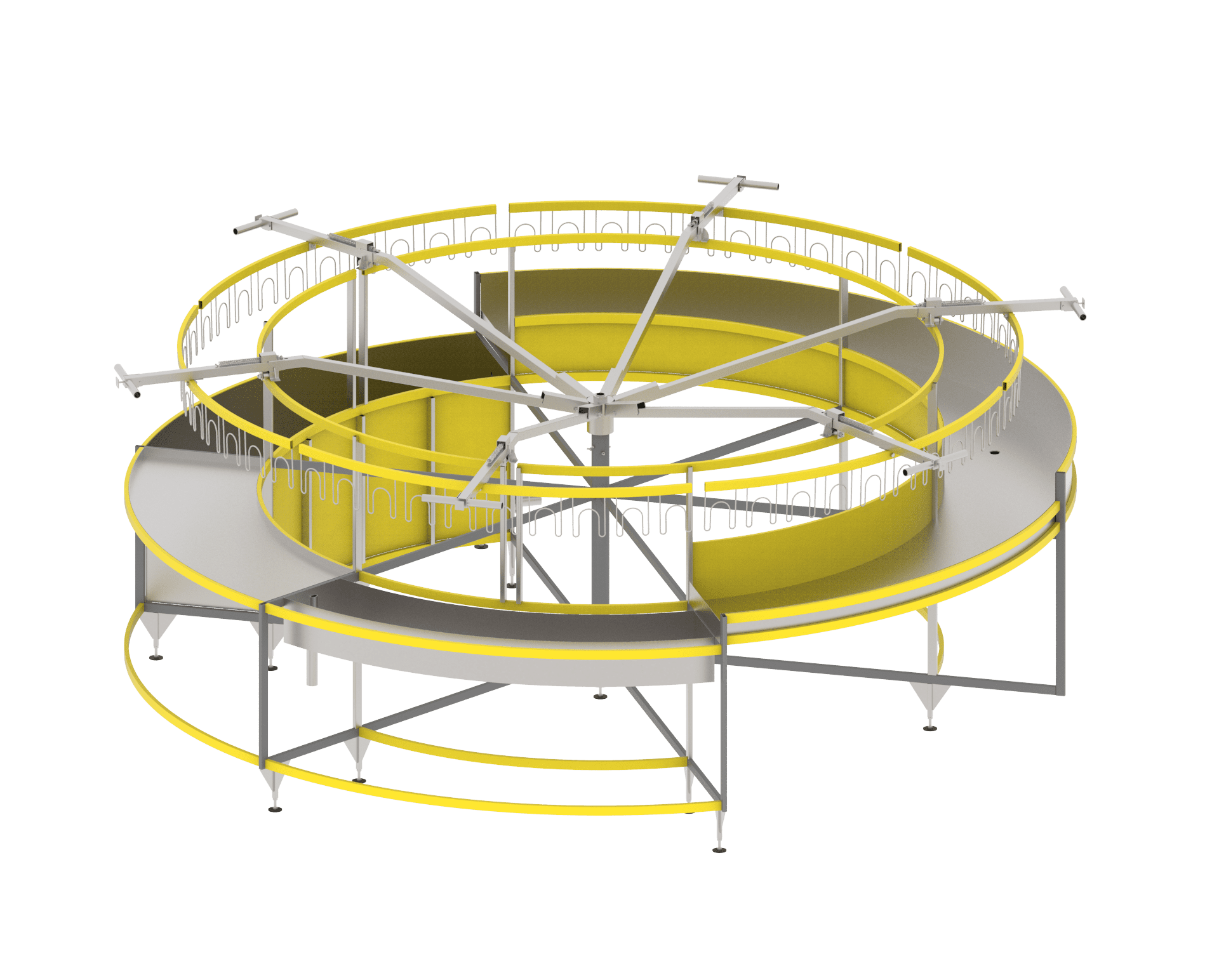

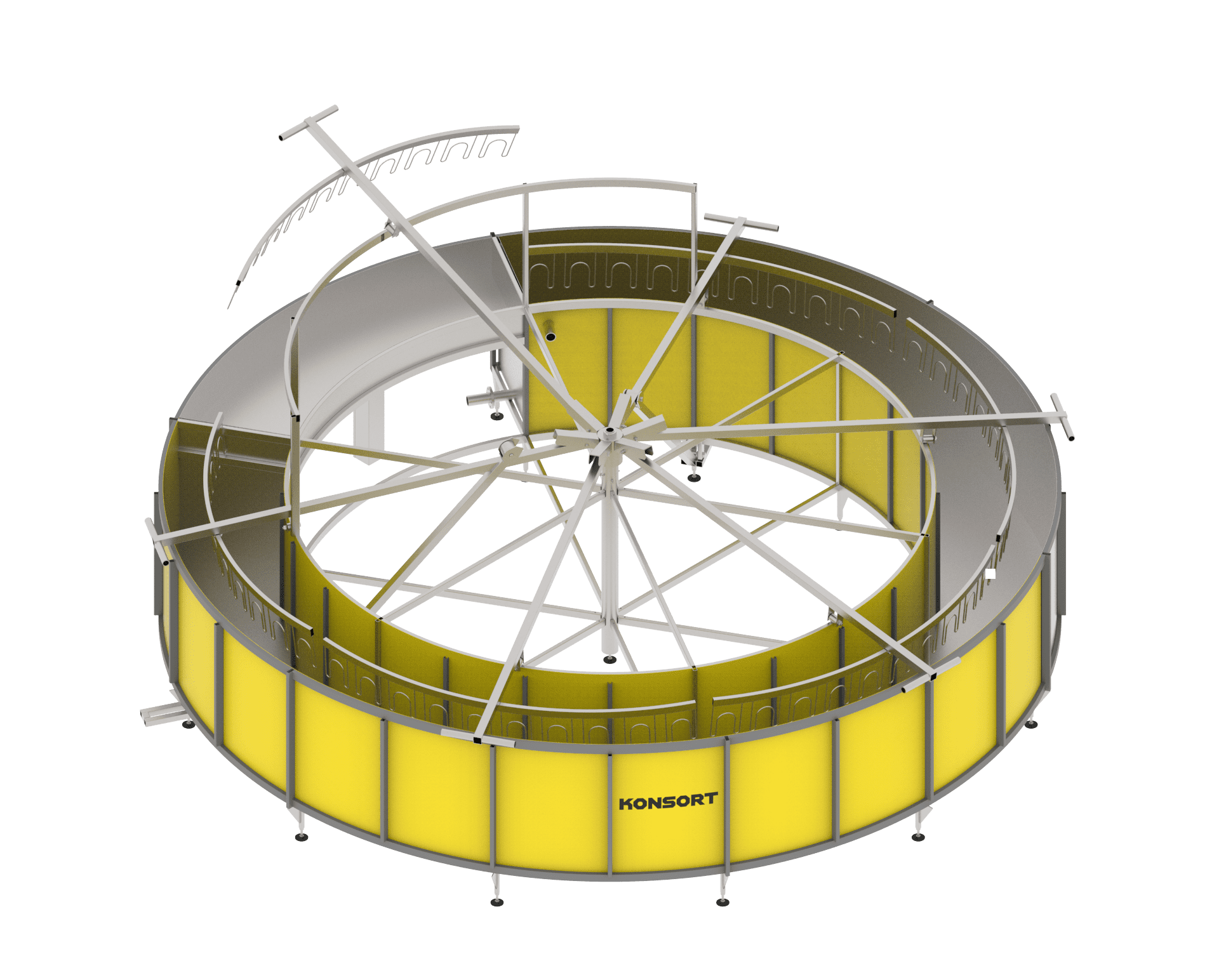

Poultry sorting and processing line

Order a poultry slaughtering and processing conveyor line from the manufacturer (Ukraine)

Description

The poultry slaughtering and processing line is a modern automated solution for enterprises specializing in meat processing and looking to improve production efficiency. The equipment is designed for complete automation of operations at poultry farms, meat processing plants, and food production facilities. The system performs bird transportation, slaughtering, processing, sorting, and delivery of the finished product. This reduces manual labor, minimizes raw material losses, and improves final product quality.

Purpose and capabilities:

The line is intended for meat-processing enterprises, poultry farms, and production facilities that handle chicken, turkey, or duck. The system provides:

- Full processing cycle — from intake to chilling and delivery to the packaging zone

- Consistent product quality due to precise and controlled processing

- Reduced human factor impact and compliance with hygiene standards

- Production optimization — reduced downtime and increased operational efficiency

Why choose a poultry processing line from KONSORT?

✅ Warranty up to 18 months

✅ Over 7000 implemented projects in Ukraine and abroad

✅ Export to more than 18 countries

✅ Service support available in every region of Ukraine

Place your order now for an automated poultry slaughtering and processing line directly from the manufacturer!

Improving in the organization of production and management up to 70%

Improving in the organization of production and management up to 70%  Productivity increase up to 90%

Productivity increase up to 90%  Lower labour costs up to 50%

Lower labour costs up to 50%  Reduction in human-related risks by 20%

Reduction in human-related risks by 20% - Enterprises exporting meat products

- Local feed mills or cooperative enterprises

- Poultry farms and agricultural producers

- Meat processing plants

- European design provides a professional and clean look

- Made of certified food grade stainless steel

- There is possibility to complete the line with extra components if necessary

- Production process is automated