In the modern world of warehouse logistics, efficiency and accuracy at every stage of order processing are crucial. KONSORT offers innovative solutions for automating the operations of receiving, accounting, moving, and shipping goods using advanced warehouse equipment. We specialize in conveyor systems that optimize logistics processes and significantly improve productivity.

Problems in warehouse operations without automation:

- High labor costs: A large number of employees is required for handling goods, which increases costs.

- Delays: Delays in receiving, accounting, and shipping can result in lost efficiency and customer service quality.

- Goods damage: Manual handling of goods increases the likelihood of damage.

- Poor inventory control: Without an automated system, accurate inventory management becomes challenging.

Solution from KONSORT:

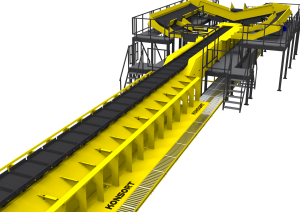

KONSORT offers a comprehensive solution for automating warehouse operations using state-of-the-art conveyor systems, specialized conveyors, and other warehouse equipment. We focus on improving goods movement, accounting, and shipping processes, ensuring a continuous flow of materials and accurate inventory management.

Key components of the solution:

- Conveyor systems for receiving goods:

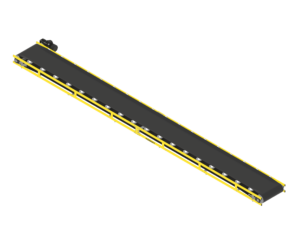

- Belt conveyors for transporting goods from trucks or containers to storage or redistribution areas.

- Rotary conveyors for changing the direction of goods flow, allowing for more efficient use of warehouse space.

- Automated material feeding systems to quickly distribute goods to appropriate sections of the warehouse for storage.

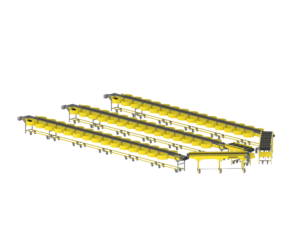

- Conveyors for inventory and sorting:

- Roller conveyors for fast sorting of goods by size, weight, or other parameters.

- Vibration tables and calibration systems for precise sorting and calibrating goods, improving warehouse efficiency.

- Conveyor systems for moving goods:

- Chain and roller conveyors for transporting heavy or large goods that require handling without additional manipulation.

- Inclined and horizontal conveyors to optimize vertical warehouse space and improve goods transport efficiency.

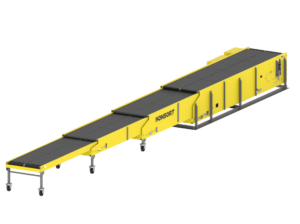

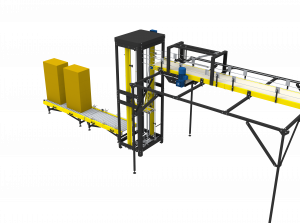

- Conveyors for shipping goods:

- Automated systems for delivering goods to shipping areas ensure quick and safe loading into transportation vehicles, minimizing time and effort.

- Robotic systems for packing and loading automate the packing of goods and deliver them to the appropriate section of the vehicle.

- Improved inventory accuracy:

- RFID systems for automatic identification of goods on the conveyor, allowing for precise inventory management and full control over stock levels.

Key benefits of automating warehouse operations:

- Reduced labor costs: Automation significantly reduces the need for manual labor.

- Increased inventory accuracy: All operations are automatically recorded, ensuring precise inventory management.

- Faster processing times: Receiving, moving, and shipping goods are carried out much more quickly.

- Improved safety: Less physical labor for employees and reduced risk of goods damage.

- Space optimization: Conveyor systems allow for maximum use of warehouse space.

Implementation Case #1

Company: LLC “Logistics-Expert”

Industry: Logistics and warehouse storage

Solution: Installation of an automated conveyor system for moving and shipping goods.

Description:

To automate the processes of moving goods from trucks to the warehouse and shipping, “Logistics-Expert” turned to KONSORT for installing modern conveyor systems. Installed belt conveyors and roller conveyors significantly accelerated receiving and shipping operations.

Results:

- Increased processing speed: Receiving goods time reduced by 30%.

- Cost optimization: Labor costs decreased by 20%.

- Improved inventory control: Automated inventory management introduced.

Implementation Case #2

Company: LLC “TechnoLogistics”

Industry: Warehouse storage and shipping

Solution: Installation of an automated goods movement and sorting system.

Description:

“TechnoLogistics” contacted KONSORT to automate goods movement and sorting in their warehouse. Conveyor systems for transporting goods of various types improved order processing speed and sorting accuracy.

Results:

- Increased productivity: Logistics processes improved by 40%.

- Reduced processing time: Time to complete operations reduced by 25%.

- Improved customer service: Delivery time reduced by 20%.

Automating warehouse operations with state-of-the-art conveyor systems from KONSORT significantly enhances the efficiency, safety, and accuracy of warehouse processes. Our equipment ensures the continuous flow of goods at all processing stages and helps companies optimize costs and improve productivity.

For businesses aiming for effective warehouse inventory management and automation of receiving, accounting, moving, and shipping goods, KONSORT’s solutions are a reliable partner for achieving high performance.