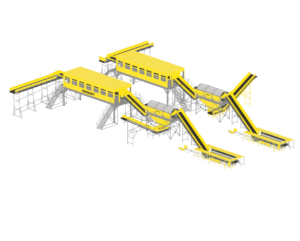

01. Automation of the waste processing landfill

At the waste processing site in the Dnipropetrovsk region, several key challenges were observed, with which the client turned to us with a request for automation, modernization and optimization of processes.