The world of conveyor systems is changing faster than we used to think. If earlier a conveyor was associated only with a moving belt, today it is a complex system with energy-efficient drives, robotic modules, artificial intelligence, and mobile stations.

For more than 18 years, KONSORT has been manufacturing conveyor systems in Ukraine. Our analytical department has collected the most exciting innovations and global examples to show where the market is heading and which solutions will soon set the rules of the game.

📦 Warehouses and Logistics: Energy Efficiency and Flexibility

1. Smart Roller Conveyors

How it works: motorized rollers are activated only when a box appears in front of a sensor.

Global examples:

-

At the Zalando warehouse (Germany), after switching to “smart” conveyors, energy consumption decreased by almost 30%.

-

Amazon uses similar systems to optimize peak loads during Black Friday.

👉 For Ukrainian e-commerce warehouses, this means: buying a conveyor in Ukraine that works on an “on-demand” principle is a real saving on energy bills and ensures longer equipment life.

2. Quiet Operation

How it works: new polyurethane belts and rollers with special inserts reduce noise and vibration.

Global examples:

-

In the DHL distribution center in Poland, after modernizing conveyor lines, the noise level dropped so significantly that employees could work without protective headphones.

👉 This is a critical factor for warehouses with night shifts in Ukraine — employee comfort directly impacts productivity.

3. Mobile Modules

How it works: conveyor sections on wheels can be moved and connected within 10 minutes.

Global examples:

-

In UPS logistics centers in France, mobile conveyors are used during peak delivery seasons.

👉 For local players (Nova Poshta, Rozetka), this is a chance to quickly scale the warehouse during seasonal demand.

🏭 Manufacturing: Hygiene and Adaptability

4. Flexible Routes

How it works: conveyors with turntables and gates redirect product flow into different zones.

Global examples:

-

At the Bosch plant in the Czech Republic, such a system reduced production changeover time by 25%.

👉 For Ukrainian manufacturers, this means the ability to quickly switch between product batches without stopping the entire line.

5. Hygienic Monolithic Belts

How it works: seamless TPU belts are easy to clean, leaving no room for bacteria.

Global examples:

-

At Parmalat (Italy), hygienic belts reduced sanitation breaks by 40%, giving +2 hours of production every day.

👉 For Ukraine’s food industry, this is the key to entering European markets where hygiene is a critical standard.

6. Quiet and Smooth Drives

How it works: gear motors with smooth start-up and reduced noise levels.

Global examples:

-

Nestlé invested in “low-noise” packaging lines for workshops with large numbers of employees.

👉 An example of how “employee comfort = higher productivity.”

🍏 Agriculture: Delicacy and Compactness

7. Gentle Sorting

How it works: brushes and soft guides replace metal paddles.

Global examples:

-

In the Netherlands, agricultural cooperatives reduced berry losses by 12% by using soft sorting modules.

👉 For Ukrainian apple, berry, and tomato producers, this means more harvest reaching the consumer without damage.

8. Spiral Coolers

How it works: the product moves upward in a spiral, cooling in the process.

Global examples:

-

Magnum (Poland) cools ice cream in spiral towers, saving up to 100 m² of floor space.

👉 Ukrainian confectionery and dairy producers can save significant space in their workshops.

9. Mobile Washing Stations

How it works: compact containerized lines that can be delivered directly to the farm.

Global examples:

-

In Spain, such stations help cooperatives wash and pack vegetables directly at harvest sites.

👉 A solution for Ukrainian farmers who need mobility and seasonal flexibility.

♻️ Waste Recycling: Durability and Automation

10. Optical Sorting

How it works: cameras detect the type of material, and the pneumatic system “shoots” it into the right bin.

Global examples:

-

In Slovakia, a municipal landfill increased the amount of sorted plastic by 20% thanks to this technology.

11. Durable Belts

How it works: reinforced rubber belts withstand impacts from scrap metal and glass.

Global examples:

-

Plants in Romania increased belt lifespan from 4 months to 1 year after switching to heavy-duty designs.

12. Mobile Sorting Stations

How it works: conveyor lines inside 40-foot containers that can be transported between sites.

Global examples:

-

In Germany, mobile sorting units are used even on construction sites.

👉 For Ukraine, this is highly relevant for modernizing municipal enterprises.

🔮 Three Strategic Innovations of the Future

-

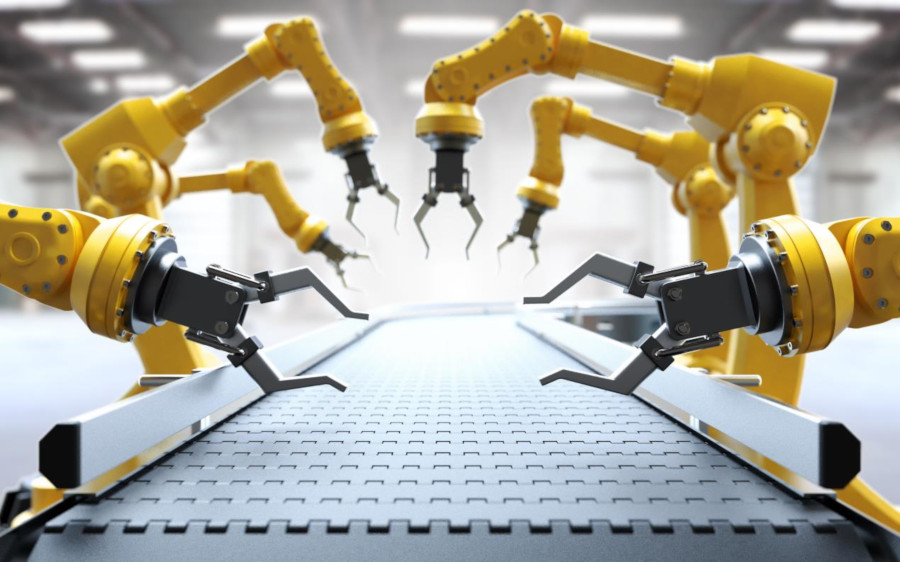

Conveyors with Integrated Robots: not just transportation, but full workstations (pick & place, palletizing).

-

AI-Flow Management: artificial intelligence predicts load and adjusts conveyor routes on the fly.

-

Flexible Transformer Conveyors: telescopic and expandable conveyors for logistics.

👉 Over the next 3–5 years, these innovations will become mandatory standards for modern enterprises.

🚀 KONSORT: Keeping Up with the Times

We are proud that many of these solutions are already implemented in KONSORT products:

-

energy-efficient drives;

-

mobile and foldable conveyors for warehouses and production facilities;

-

hygienic solutions for the food industry;

-

heavy-duty belts for waste recycling;

-

sorting systems for the agricultural sector.

Our approach is simple: we don’t wait for the future — we build it together with our clients.

👉 If you want to order a conveyor solution in Ukraine, contact the experts at KONSORT. We will help you implement projects of any complexity — from small farms to international warehouses.

🚀 What This Means for KONSORT and Our Clients

-

We already use most modern technologies — from energy-efficient drives to hygienic solutions for the food industry.

-

Next steps: invest in AI-driven control, robotic integration, and mobile solutions.

-

For enterprises assembling electronics, we are ready to provide:

🔹 anti-static conveyors for manual assembly;

🔹 compact in-plant conveyor lines;

🔹 mobile solutions for quick production reconfiguration.