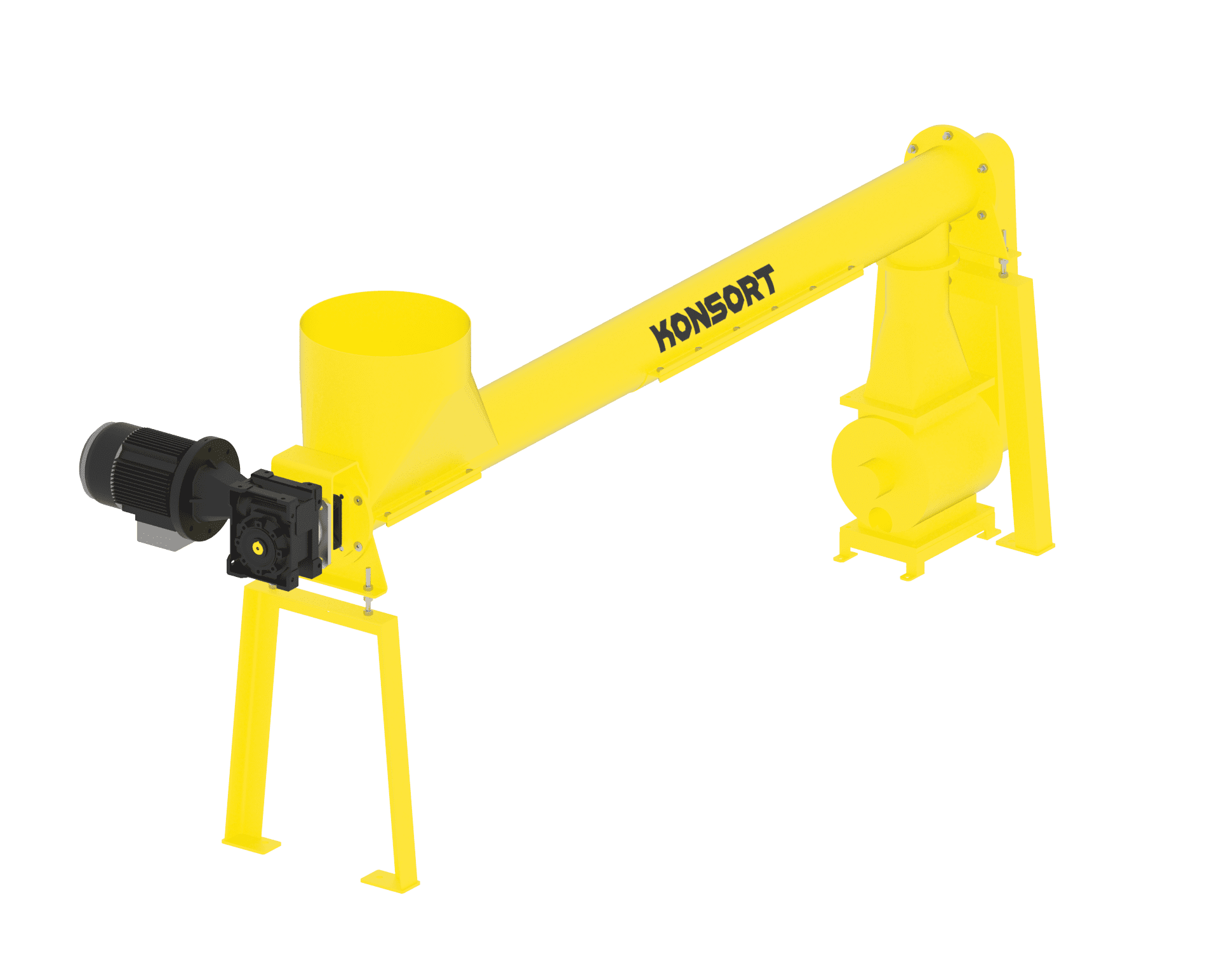

Berry stem separator

Berry stem separator by KONSORT — a reliable solution for automating berry processing

The berry stem separator is a specialized piece of equipment designed to efficiently and delicately remove the stems from berries. It is widely used in processing plants, berry farms, and in the production of juices, jams, frozen berries, and other berry-based products. This machine significantly increases the processing speed while reducing the need for manual labor.

Operating principle

The separator works using a rotational or vibrating mechanism that gently removes the stem while the berry moves through the processing area. The design takes into account the specific characteristics of different berry types — such as blueberries, bilberries, currants, honeysuckle, and others. Thanks to precisely calculated gaps and bearing assemblies, the machine preserves the commercial appearance of the berries.

Advantages of the KONSORT berry stem separator

✅ High productivity — processes large volumes of berries quickly

✅ Gentle separation — minimizes berry damage and preserves structure

✅ Food-grade materials — all contact parts are made of food-grade stainless steel (AISI 304)

✅ Compact and mobile — easily integrates into existing production lines

✅ Customizable — tailored settings for different types of berries

✅ Energy-efficient — low power consumption

✅ Service and warranty — full support throughout the equipment’s life cycle

Why buy a berry stem separator in Ukraine from KONSORT?

- We are an experienced manufacturer specializing in automation equipment

- We offer tailor-made solutions for every client

- We provide service, warranty, and operator training

- You can buy directly from the manufacturer at an affordable price — no intermediaries

- We work with businesses across Ukraine and internationally

Improving products quality and grade

Improving products quality and grade  Productivity increase up to 70%

Productivity increase up to 70%  Lower labour costs up to 30%

Lower labour costs up to 30%  Reduction in human-related risks

Reduction in human-related risks - Presale product preparation enterprises

- Freezing and packaging factories

- European design

- Process automation

- Preservation of the properties and qualities of the product