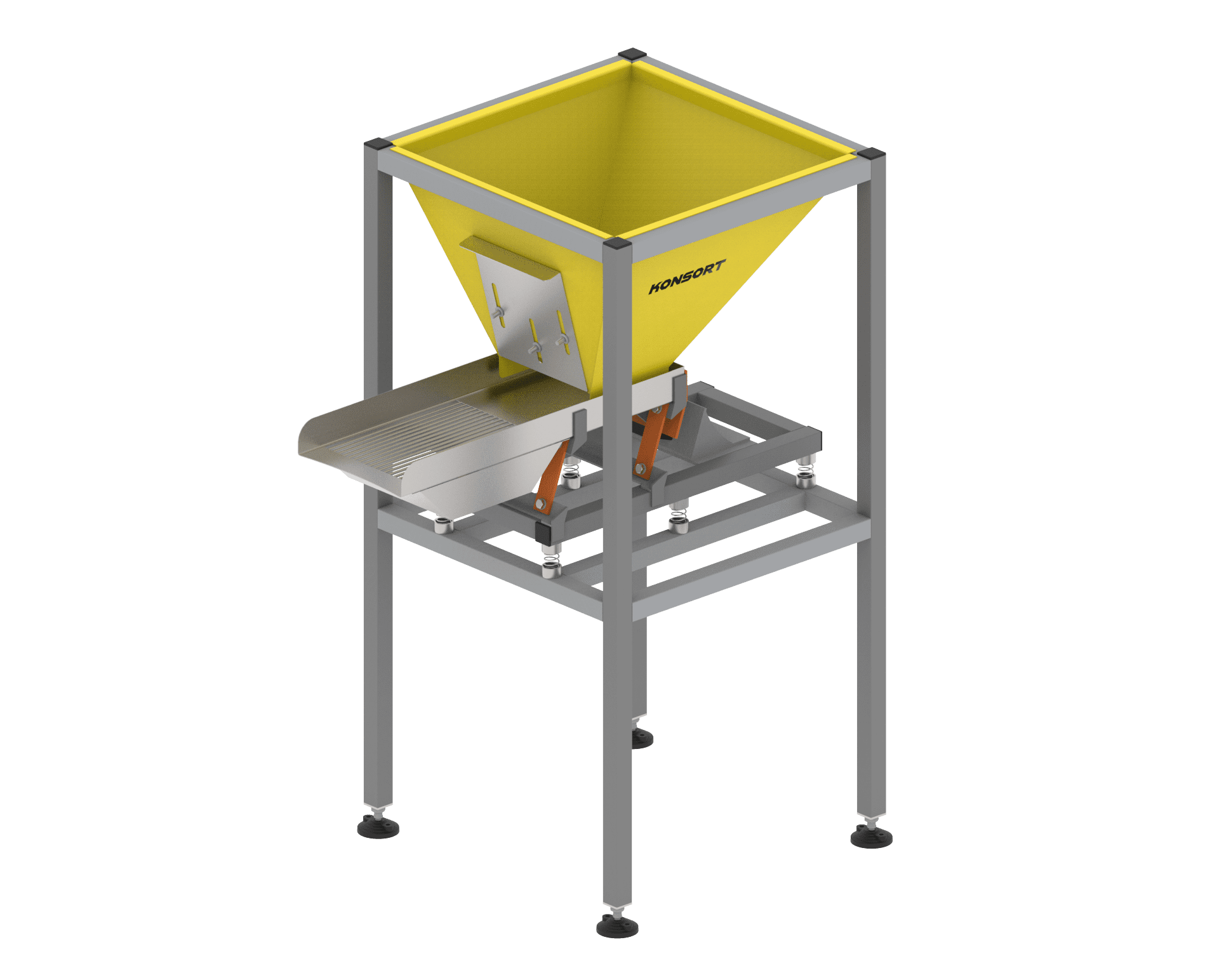

Vibrating hopper

The vibratory hopper is a specialized piece of equipment designed for the uniform feeding, sorting, and accumulation of bulk or discrete materials in production lines.

KONSORT, a Ukrainian manufacturer of vibratory hoppers with over 15 years of experience, offers reliable and energy-efficient equipment that can be ordered directly from the manufacturer at an affordable price.

Functionality:

-

Automatic feeding of raw materials or semi-finished products;

-

Product flow leveling;

-

Preliminary sorting and distribution;

-

Accumulation and buffering before the next processing stage.

Applications:

-

Vibratory hopper for the food industry — feeding nuts, dried fruits, grains, seeds, tablets, etc.;

-

Packaging lines — for even loading of filling equipment;

-

Sorting systems — for pre-classification by size or weight.

Advantages:

-

Manufactured in Ukraine — no extra costs for imports;

-

Durable construction made of food-grade stainless steel (AISI 304);

-

Low energy consumption;

-

Adjustable vibration intensity;

-

Easy maintenance and long service life.

You can order a vibratory hopper at a low price today and receive an effective solution for food or other industrial applications — saving your time and resources.

KONSORT manufactures vibratory hoppers in Ukraine according to custom specifications: volume, vibrator type, feed height, construction material, and integration with existing lines — all considered during design.

Call us now or leave a request on the website to buy a vibratory hopper directly from the manufacturer at a competitive price.

Improving products quality and grade

Improving products quality and grade  Reducing product damage and waste

Reducing product damage and waste  Productivity increase up to 70 %

Productivity increase up to 70 %  Workforce optimization

Workforce optimization - Enterprises and factories specialized in processing, packing, and freezing berries, fruit, vegetables, mushrooms and nuts

- Wholesale warehouses and depots

- European design

- Productivity process automation

- Payback in 9 months